High project maintenance costs? That’s because you touched the “red bar line” of engineering quality

The cost of project maintenance mainly concentrated in waterproof, stone, wood finish, glass brick, and other sub-items, to the company, caused greater economic losses, serious impact on the company’s brand.

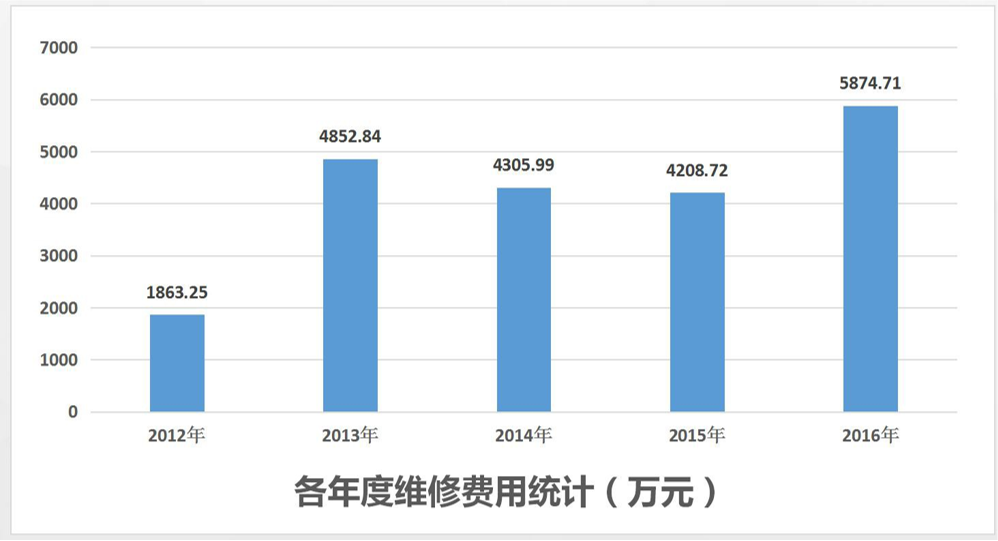

Let’s start with a set of data: (Annual maintenance cost statistics for a company)

To this end, this article combs the “quality red bar line” problem, compiles practical technical plan, ensures the construction quality, effectively controls the project cost.

01

Waterproof sub-items

1.1

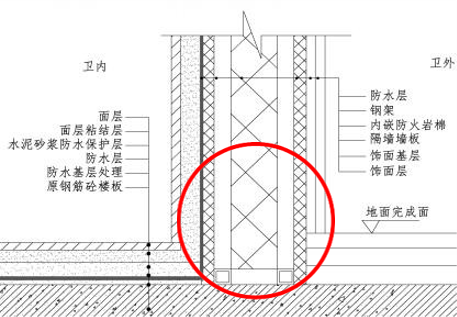

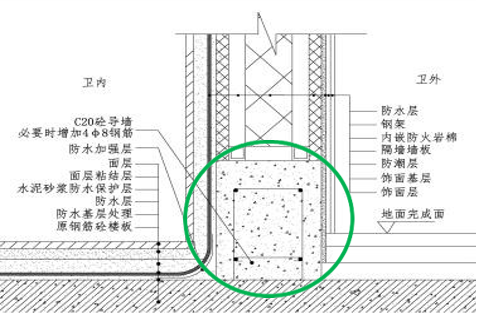

Lightweight partition wall and wet space partition wall practice

Wrong practices . . . the right practices…

Lightweight partition wall and damp space partition wall lower part must be set up following the specification requirements of the concrete guide wall, the height should be at least higher than the adjacent room building, ground finish layer above 200mm, width according to design requirements, concrete strength level is not less than C20.

1.2

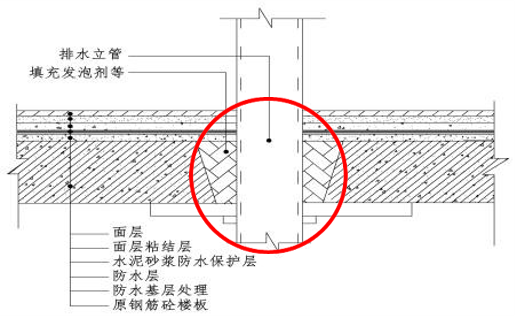

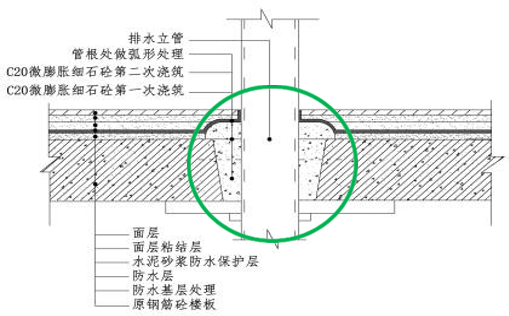

The practice of wearing floor pipe parts

Wrong practices . . . the right practices…

(1) The gap between the floor pipe and the original structure should be filled with micro-expansion C20 fine stone concrete, or other leak prevention measures;

(2) Concrete must be poured twice, the first pouring to 2/3 of the thickness of the floor, the molding process should be used in the finished mold tool.

1.3

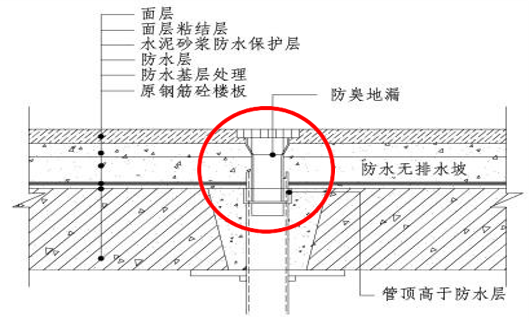

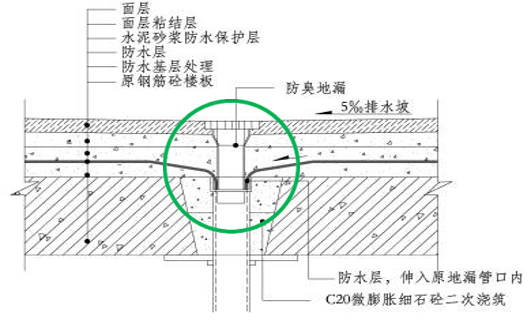

Ground leakage site practices

Wrong practices . . . the right practices…

(1) The in situ leaks must be flush with the original structure floor, not higher than the surface of the structural floor;

(2) Shower floor should be 10mm lower than other ground and do ≥ 5 inches drainage slope, ground leakage is located at the lowest point of the slope, conditions allow, it is appropriate to set double ground leakage, to ensure that no water.

1.4

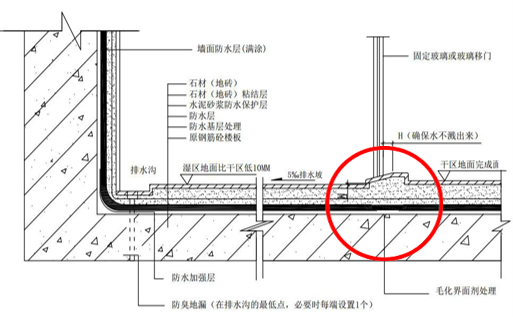

Shower interval off the lower water stop practice

Wrong practices . . . the right practices…

(1) Before the flat construction must be in the bathroom, shower door and shower space broken glass lower part with fine stone concrete and steel bars (recommended to use steel plate water stop) to make a stop water tank, should be made into an equal width or narrow lower width form, water stop bar top distance from the bottom of the finish 5 to 10mm;

(2) The water stop must be closely integrated with the connected concrete base to form a closed ring without leakage.

01

Stone sub-items

2.1

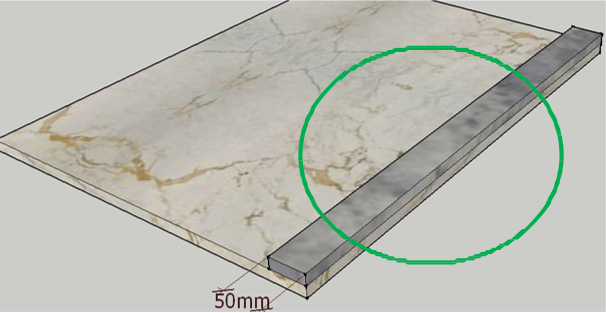

Dry hanging stone back strip reinforcement practice

Wrong practices . . . the right practices…

(1) Stone thickness is less than 20mm, must be added back bar, back bar prohibited the use of beige loose material stone, back strip width 50mm, suitable for long;

(2) Dry pendants, back bar fixation must be epoxy AB adhesive paste, the use ratio is 1:1, cloud stone glue can only do temporary point solid.

2.2

Dry hanging stone steel frame grass-roots requirements

Wrong practices . . . the right practices…

Dry hanging stone steel frame must be firm, steel frame should be fixed in the concrete structure, if you can not avoid with the lightweight block partition wall fixed, should take measures such as through the wall gold anchor plate, strictly prohibited with expansion bolts directly fixed to the lightweight block, steel surface must be anti-corrosion treatment, wet areas must be 304 stainless steel dry pendants;

2.3

Over-top stone dry hanging requirements

Wrong practices . . . the right practices…

Over-top stone dry hanging must be reinforced and reinforced treatment, increase the strength of stone, it is recommended to use aluminum honeycomb composite stone.

2.4

Wet paste stone back-net treatment method and protective construction requirements

Wrong practices . . . the right practices…

(1) Stone unsaturated polyester back mesh glue must be removed before brushing the protective agent in the stone factory, such as beige loose stone can be used cement-based back mesh glue;

(2) Stone must adopt oily protection, to prevent oily protection from affecting bonding strength, the bottom surface should be enhanced treatment;

(3) Light-colored stone dry hanging with AB dry hanging, to prevent stone spit oil, red and yellow, the knife site must be treated with the same protective agent.

2.5

Ground wet paste stone dry mixed mortar layer and maintenance requirements

Wrong practices . . . the right practices…

(1) Dry-mixed mortar layer thickness should not exceed 50mm if more than 50mm need to be leveled twice;

(2) Stone construction after 3 days is not allowed to get on,7 days are not allowed to load, the stone paste should be 14 days after the filling process.

2.6

A large area of stone wet patch retention requirements

Wrong practices . . . the right practices…

(1) When laying a large area or narrow plate stone, find the flat layer, the surface layer must be set the telescopic seam, the telescopic seam spacing should match the building structure, material performance, surface material layout, the maximum, not more than 10m set a telescopic seam;

(2) Artificial stone plate between the appropriate 1.5mm seam,10m must be left within 10mm telescopic seam, suitable for the use of finished elastic telescopic seam treatment.

03

Common items

3.1

The wooden base skeleton is fixed

Wrong practices . . . the right practices…

The wood base skeleton is prohibited from using nail fixation, must be fixed with self-tapping screws.

3.2

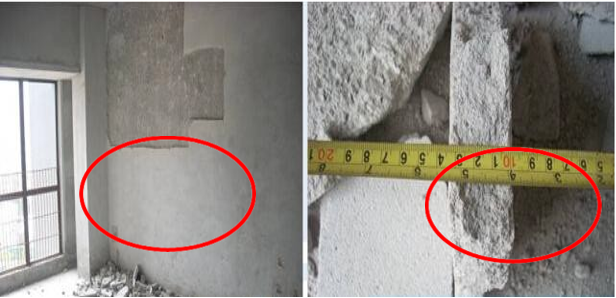

The practice of plastering layers

Wrong practices

The right thing to do

The plastering works should be carried out in layers, and when the total thickness of the plastering is≥ 35mm, strengthening measures should be taken.

3.3

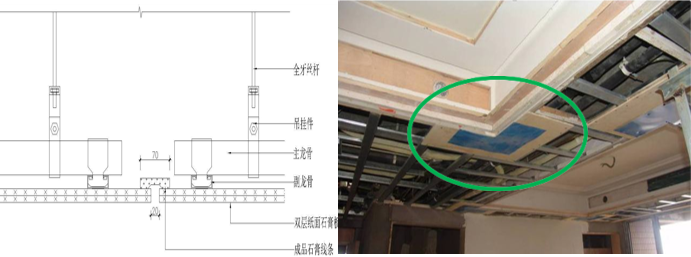

Large area or narrow long ceiling practice

Wrong practices

Wrong practices

Large area or narrow shape of the overall ceiling, tight stitching processing plate ceiling area ≥ 100m2, or one-way length of ≥15m should be set the telescopic seam, the shape of the ceiling corner should be set anti-cracking measures.

3.4

Lamps, air vent equipment fixed

Wrong practices . . . the right practices…

Lamps, air vents, and other equipment should not be installed directly on mineral cotton or fiberglass board.

04

Hydropower special

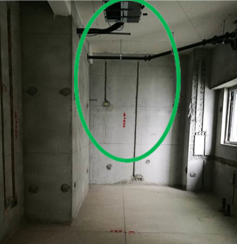

4.1

Wire laying must prohibit “naked wire”

Wrong practices . . . the right practices…

Wire laying must not be exposed, must be protected by casing, prohibited “naked wire”.

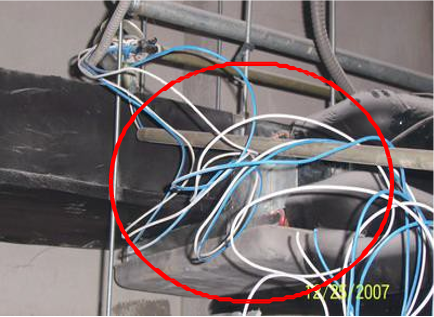

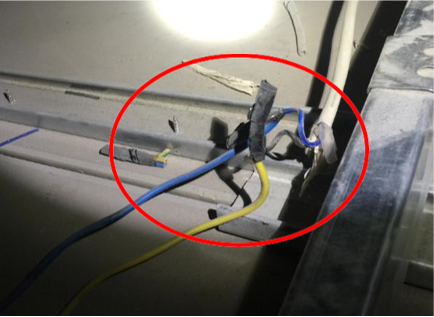

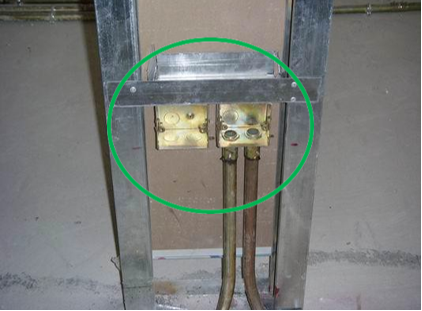

4.2

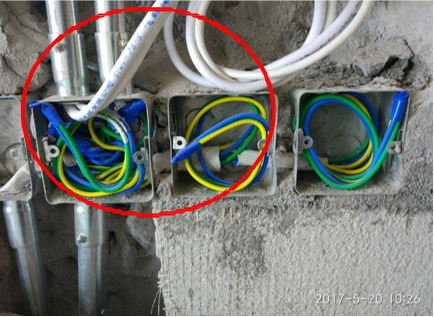

Wire connectors should not be exposed outside the online box

Wrong practices . . . the right practices…

Wire connectors should not be exposed outside, and the head should be inside the online box, wire boxes between the joints are strictly prohibited.

4.3

The electric work industry is strictly prohibited to live operation

Wrong practices . . . the right practices…

In the ceiling operation of the first power cut, power inspection, and someone to monitor, hang up the warning signs, and then operate, “strictly prohibited live operation.”

4.4

When the wire is laid through the tube, there must be no joint kink in the tube

Wrong practices . . . the right practices…

When the wire is laid through the pipe, there must be no joints or kinks in the tube.

4.5

Wood finishes, soft packages on the installation socket, switches must do a good job of fire prevention measures

Wrong practices . . . the right practices…

Wood finishes, soft bags on the installation of sockets, switches must do a good job of fire prevention measures, should use the corresponding metal frame plus and decorative surface flush, otherwise, there should be fire cloth and other isolation measures.

4.6

Sockets, switch bottom boxes must not be fixed with flammable materials

Wrong practices . . . the right practices…

Sockets, switch bottom box shall not be fixed with flammable materials, the use of flame retardant materials fixed.

4.7

Line pipes are not allowed on the bathroom floor

Wrong practices . . . the right practices…

The bathroom floor is prohibited to lay wire pipe, the heating pipe should be from the corner of the bathroom over the water sill.

4.8

It is strictly forbidden to share a tube or a back box

Wrong practices . . . the right practices…

Strong and weak power should be separated from the line, it is strictly forbidden to use strong and weak power to share a tube or a back box.

4.9

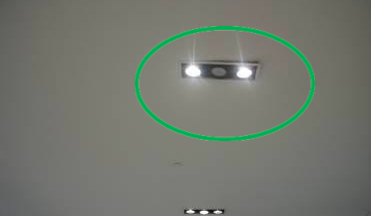

The way the lamps are installed and secured

Wrong practices . . . the right practices…

Lamps weighing less than 1kg, quartz spotlights and other facilities can be installed directly on the ceiling surface of light steel keel gypsum board, lamps weighing less than 3kg should be chain or pipe hanging, lamps weighing more than 3kg, air conditioning, ceiling fans, etc., should be hung directly on the building load-bearing structure.

Wrong practices . . . the right practices…

Lamps with a mass greater than 10KG, fixtures, and suspension devices shall be tested for strength at a constant average load of 5 times the weight of the lamp, and shall not last less than 15min.

The implementation of the quality red bar line will be advanced from the following aspects:

1, training propaganda

Companies, branches to organize exchanges, learning;

Use the online learning platform, push to the project department to learn;

Add “Quality Red Bar Line” related content to the Quality APP Check module;

During the inspection process, the inspection is carried out in comparison with the project department to discuss and communicate.

2, the process of implementation of supervision

Within three months after the release of inspection, notification, training-oriented: through the district supervision inspection score, the implementation of the “quality red bar line” and feasibility of the investigation, and the results of the inspection feedback to the company’s assessment, further optimization, and adjustment;

To organize targeted training for the problems found in the inspection;

Three months after the release will be based on the results of the inspection to be held accountable, and following the company’s red and yellow card system to enforce the punishment;

One year after the release of the “Quality Red Bar Line”, according to the results of the inspection and the annual maintenance costs re-evaluation, for better implementation, lower maintenance costs to general inspection items;

“Quality red bar line”, is the bottom line of construction quality management, lifeline, no department, personnel can not violate!

The formulation of “quality red bar line” and floor implementation, through rolling sales management, the overall improvement of the company’s project construction quality, effectively reduce the cost of project maintenance, maintain the company’s brand image.