Want to do a good job of batch fine decoration, first understand these decoration key processes to say

Because of the large number of hardcover repair and construction units, the overall management requirements are relatively high, project managers often face these difficulties:

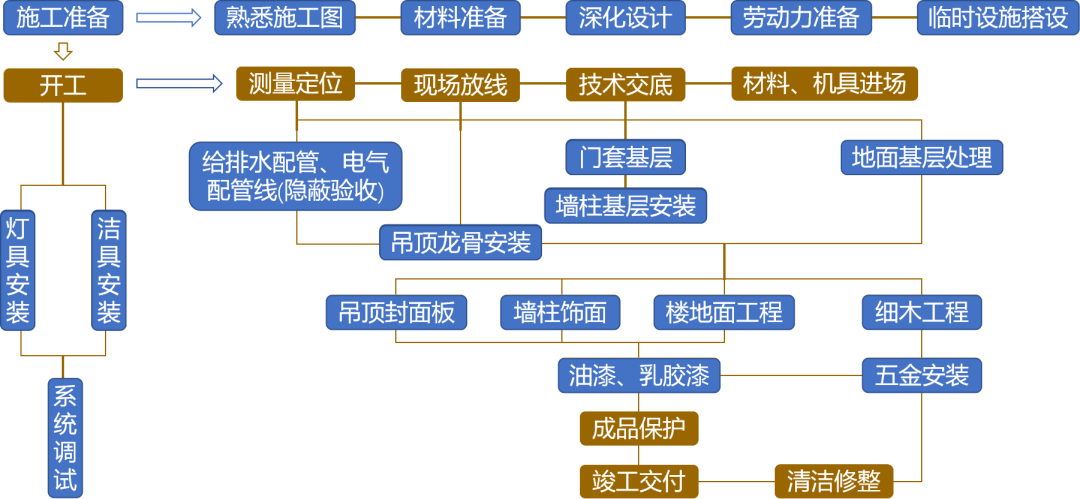

1, hardcover repair and construction units, a variety of projects and processes cross-operation, high process arrangement requirements, control difficulty are also large, the need for detailed pre-planning and overall command.

At the same time, because each floor implementation process is different, the need for building materials is also different, such as can not do strict on-site control, it is easy to appear the overall collapse of the project, quality problems frequently.

2, the owner of the construction quality of the sensory requirements are high, the degree of refinement of the construction is relatively strict, the details are not up to standard, affecting the completion of acceptance.

3, the project side has direct contact with the customer, the customer is very concerned about the integrity of the finished product, resulting in the current fine decoration has become a complaint “heavy disaster area” …

Based on the previous problem, next, we will interpret the following 4 points, the key process of fine decoration project control practices, to do a good job of fine decoration, not only to control costs, rush the duration but also to maintain quality, the construction requirements are very high.

01

With the implementation of the “model first” system, the site problems will be exposed on time, for the later construction to provide a basis, but also better control of the site

1.1

Drawing triage, team leader contract signing, technical bottom

1, site, drawings, pre-sales model three comparison for the problem summary, to ensure the normal construction of bulk decoration;

2, the project department to the monitor to take the “clearing” mode, the project mud working, carpentry, hydropower, paint sub-professional contractors, to ensure that the quality of the hidden projects meet the standards when entering the field to sign a labor contract, do not use the large dry dry mode, to ensure that the project can be controlled management;

3, before the start of the monitor, workers for construction quality, safety, progress to the bottom, to avoid rework in the construction phase, delays in the work period matters.

1.2

Build a library of material models

1, material sample confirmation, to meet the requirements of the United States materials, on-site materials for material model library comparison, to ensure material quality standards.

2, the material model must be installed, to keep and check, labeled with the name of the material and the location of use, the finished model must have the signature of the person in charge of the designer to confirm before bulk material.

1.3

With civil total package indoor handover

Hardcover repair units before the construction of the main contractor for handover acceptance, one room, one inspection, acceptance of the main content, and qualified standards as follows:

1.4

Model guidelines

The process model guidelines

Paint process, wall flour brushing process, wall measuring process, tile layout, ceiling process, waterproofing process between kitchens and bathrooms.

Delivery of the model guidelines

Central processing area planning and layout

02

Reasonable arrangement of the construction process and construction process, strengthen the awareness of the protection of finished products, to ensure the quality of the project

2.1

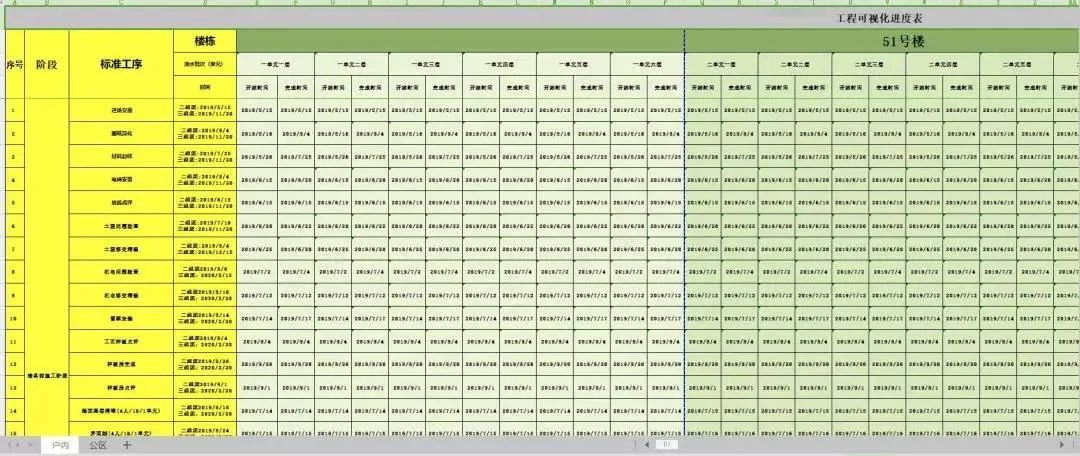

Develop a progress quality visual management table

Develop a visual management table of the progress of each building, better control of each building, easy party A, supervision units at any time to track in place.

Logical planning:

Construction planning:

Related schedule:

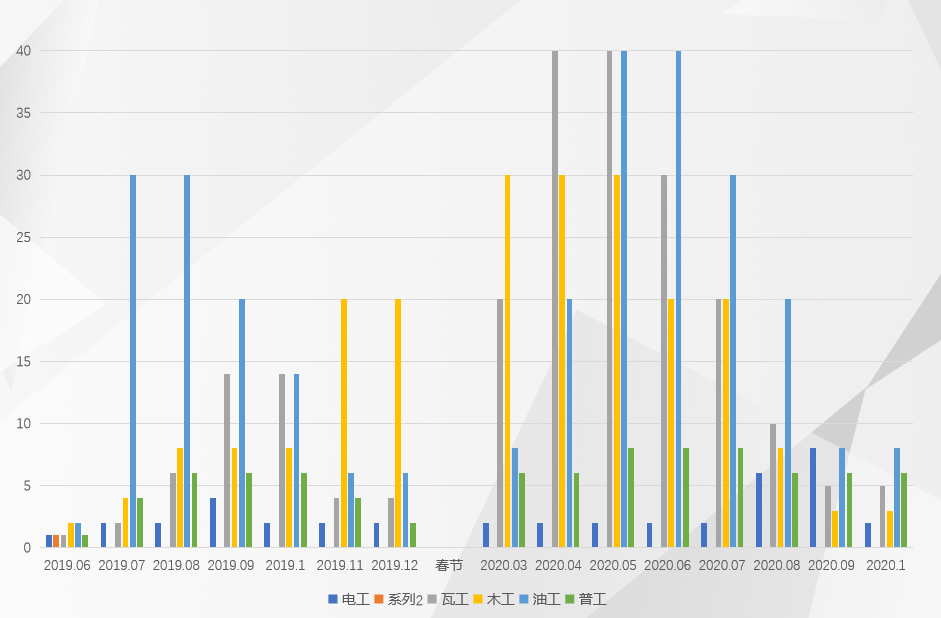

Labor Plan

Visual progress control

2.2

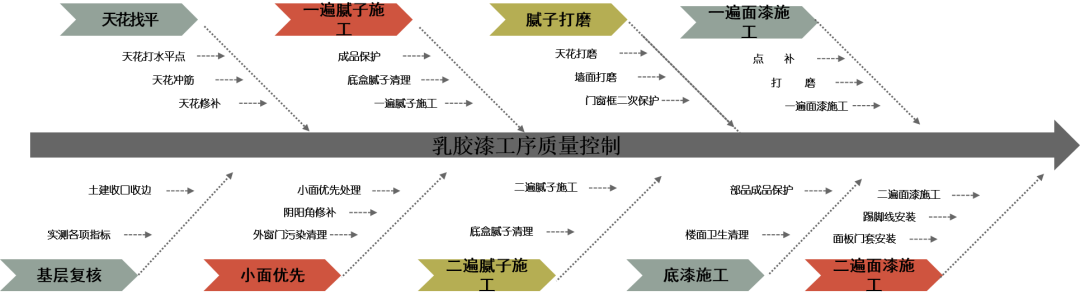

Lot control of latex paint process

Quality control of latex paint construction process

Process requirements:

(1) The and yang joints should be sewn with plaster and should be used with corner guard strips and bandage paper.

(2) When the plaster is greater than 35mm, it needs to be layered with a steel mesh or glass fiber mesh reinforcement to prevent cracking.

(3) Grass-roots gypsum on the wall, different materials between the hanging net (glass fiber net) reinforcement, and up and down the connection width of not less than 100mm.

The area is repaired with infrared radiation on the bullet line and the problem at the yin and angular area

Kicking line part full of testing door cover edge each set of acceptance

2.3

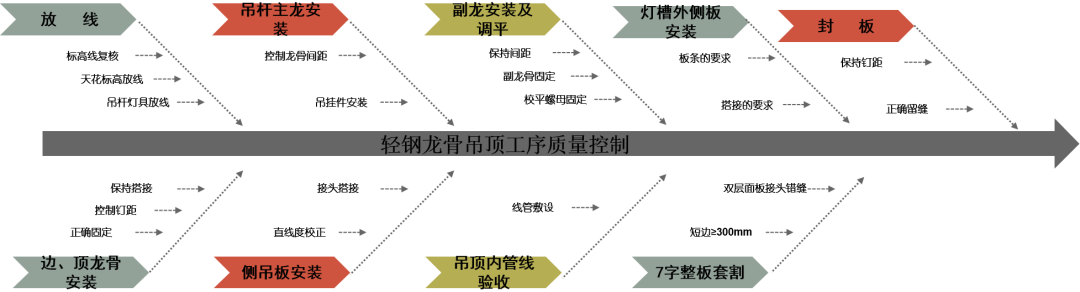

Light steel keel gypsum board ceiling process batch control

Light steel keel ceiling process quality control

Process requirements:

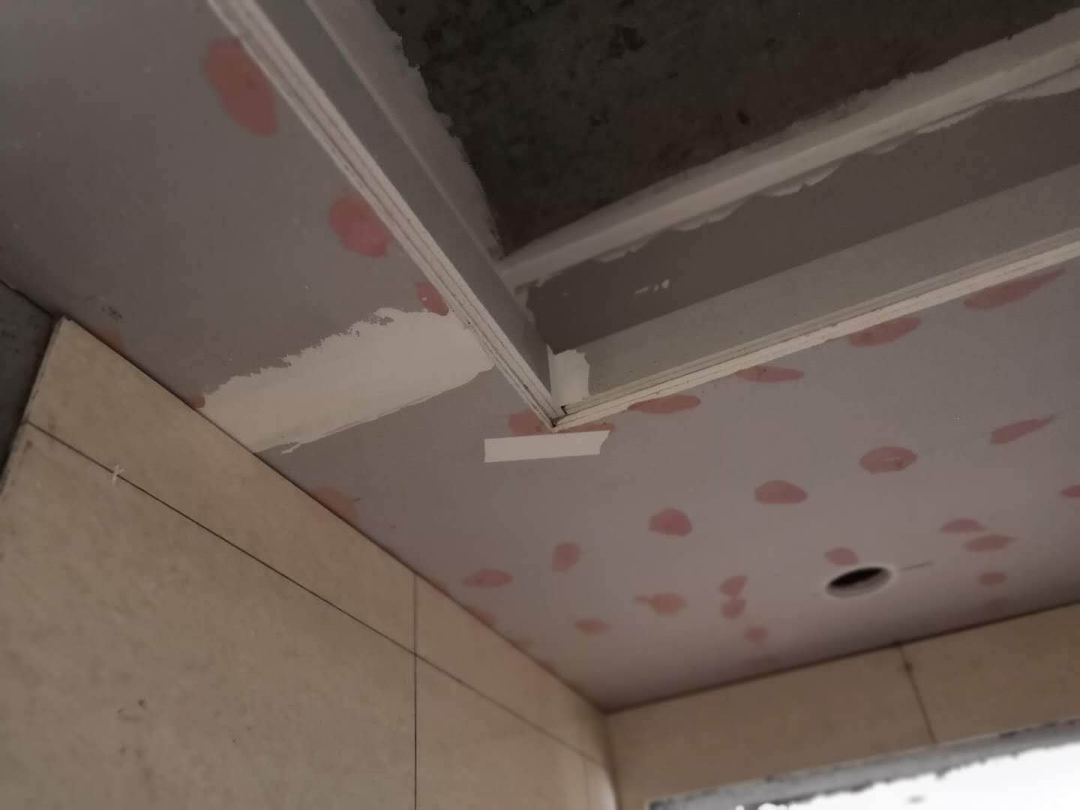

(1) The gypsum plate corner seal must cut L-type, and the width of the first layer of gypsum board on both sides is not less than 600mm, and the width between the two sides of the second layer of gypsum board is not less than 1000mm.

(2) The edge of the plate shall not be seriously damaged, the cutting surface is rough and unrepaired;

(3) Light steel keel and gypsum board in the centralized processing area unified cutting processing, the site is not allowed to cut and secondary deep processing.

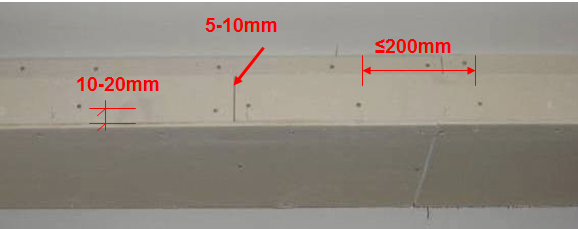

(4) The spacing of the boom < 900mm,300mm from < the wall edge, 1000mm from the main keel spacing < 300mm from the wall edge, < and 400mmfrom the < of the secondary keel, 200mm from thewall<. The first gypsum board screw spacing < 600mm, the second layer gypsum board screw spacing < 200mm.

The T-word corner of the ceiling corner

The T-word corner is pulled obliquely with a bandage

Gypsum board Self-tapping screw spacing

2.4

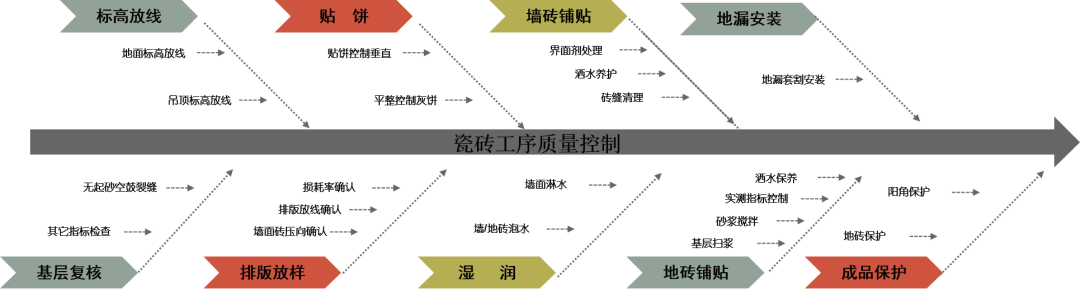

Bulk control of tile operations

Quality control of the tiling process

Process requirements:

(1) Wall tiles should be laid before the deepening layout, the formation of layout to determine the tile loss rate.

(2) Wet paste higher than 1200mm should increase the hanging net to prevent shedding, tiles should be soaked completely before the placement.

(3) When wet on a concrete wall or a concrete slab wall, cement glue should be used to pull the wall.

(4) Yin and yang angle tile must control the verticality of yin and yang angle and yin and yang angle brick seam size is consistent.

Basic empty drums, cracking, etc. check the wall water 1 hour before the paving

Glazed brick Before laying with a water-soaked, glazed brick wipe, drain, and dries

Glue batch scraping uniform, cross grooves, tile patching, glue staining

Tiles are laid to check the thickness and reasonableness of the tiles

After the tiles are laid, the water is watered to maintain the tiles

Empty drum check after 24 hours

Tile wall brick fixed-point bullet line – Tile floor tile fixed-point bullet line

Tiles are left seamed 2mm in the same size . . . after the tiles are finished clean

Tile chamfers are centrally processed

Ground leakage eight-word foot centralized processing

The water pipe opener is open

2.4

Finished product protection

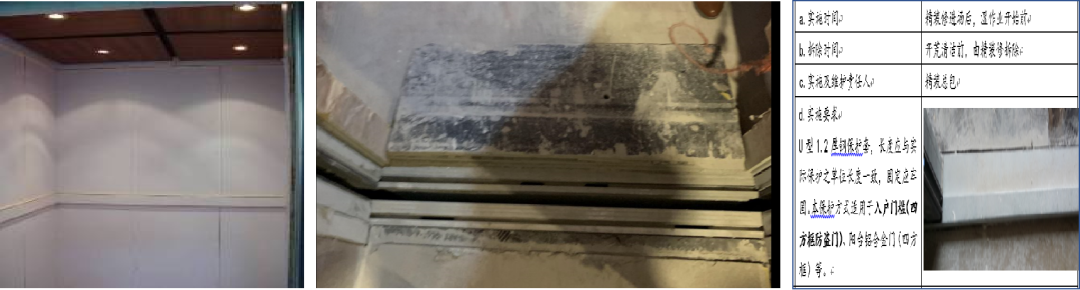

Elevator protection: . .

(1) Elevator threshold with 15mm carpentry board square box, to protect the elevator car bottom sill, the use of carpentry board / nine percent board will be the elevator car box wall, floor, top surface protection, set small flip board. After the handover, a professional elevator driver is equipped with a walkie-talkie. Non-professionals are not allowed to build elevators, elevator drivers at any time every day on the elevator car, floor, and elevator car door grooves to clean up, to maintain the elevator car clean and normal use.

(2) Floor tiles: Protect at any time after completion. The ground is covered with a finished protective film.

(3) Tile yang angle: the use of a special corner guard strip in the middle, 1.2 meters above the ground for protection.

(4) Wall: Complete the putty before it is finished, finish it, finish it two or three times before the hardcover delivery, polishing, and lacquering.

Elevator car protection / elevator door hole protection / threshold stone protection

Door cover, yang angle, stair protection:

9-centimeter wooden splint According to the size of the door cover to make a U-shaped protective case, firmly fixed around the door cover, height is not less than 1.2 meters, U-shaped flip width needs to cover the door cover.

The finished yang angle guard angle is implemented yang angle guard angle, the angle height is not less than 1.2 meters, the width of the wings is not less than 30mm, the installation should be firm.

Protect the finished yang angle guard with a 9-centimeter splint or an L-shaped protective case with a 9-centimeter splint, and install securely.

Flooring, floor tiles, stone, railings, wire box finished product protection:

2.5

Sign the Regulations on the Administration of Large General Packages

1, each subcontracting unit to the total package unit to hand over the deposit;

2, each subcontracting unit progress by the specified time node to complete, if not completed the extension of one day need to have the corresponding disciplinary measures;

3, after the completion of a single process of construction inspection and acceptance, must be timely finished product protection (later if there is damage to the total package must be after acceptance of the finished product protection completed).

4, for each sub-contracting unit in the acceptance at the same time, the household defects should not exceed 5%, more than 5% of the penalty (must be self-tested at the time of inspection).

5, after the completion of all single-operation construction by the total package to control the next single operation start construction time node (not allowed to enter the construction at the same time, such as if found immediately stop work).

6, all subcontracting units in the construction of their garbage to do timely clean downstairs (such as not cleaned, the second day of the total package to clean up).

7, each sub-contracting unit monthly reporting progress must have a total package confirmation before it can take effect (progress payment with finished product protection photos, inspection, and review records).

8, each subcontracting unit in the construction process, such as urging in the problem, timely communication with the total package to avoid causing rework, quality progress problems.

03

In-depth study of the project difficult process, reasonable arrangement of the process, to avoid rework

3.1

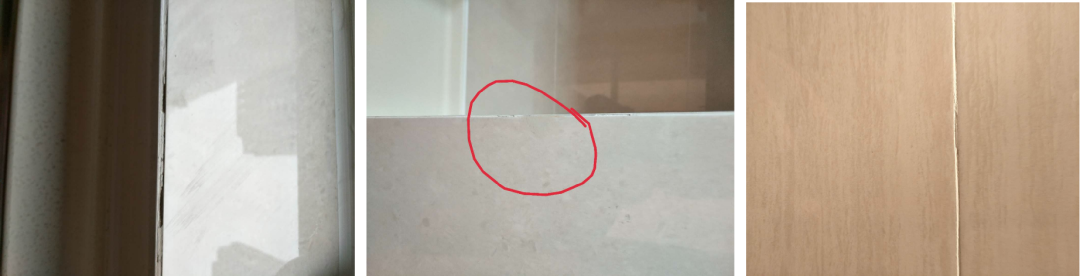

The problem of seams

1, wall tiles sewing ash clean-up is not complete;

2, individual location because the mud cross card mosaic is not deep enough, resulting in the hook after the black print;

3, after the seam, is not cleaned in place, the rear cleaning team with a blade when the individual positions fall off.

Treatment scenarios:

The hook check is the key point of item acceptance control, arrange for someone to check and rectify the place is not in place, wet operation process mud cross card use to do a good job of bottoming and control.

3.2

Paint problems

1, paint comprehensive acceptance after the repair color spots;

2, individual switch panel position after the leak repair color difference (do not exclude the installation of the panel when the bump defects);

3, door covers, kick lines, switch panel position installation of paint pollution marks.

Treatment scenarios:

When the paint is molded and repaired, be sure to apply the primer and then roll the paint, roll paint when the roller pattern should be consistent with large area construction, such as repair-marks serious, must be used the whole wall painted rolling way to repair.

3.3

Cleaning issues

Due to the large volume of delivery, fine cleaning after repeated pollution, the subcontracting units left indoor rectification work is not completed, cleaning personnel business ability mixed uneven, high-volume cleaning management personnel can not keep up with the impact of factors such as.

Treatment scenarios:

Close the cleaning stage to do respond to the people, to ensure that all parts of the acceptance after the closing, the progress of the early stage of control is very important, to give comprehensive acceptance and cleaning to leave sufficient time to avoid cross-operation, closing the door acceptance is the last line of defense, must not relax.

3.4

Three defense “anti-cracking, anti-aircraft drum, anti-leakage”

Anti-cracking measures for walls:

Anti-aircraft drum:

(1) Before the construction, check the original wall for empty drums, shedding and other hidden dangers must not blindly start work;

(2) To prevent the glass brick empty drum and shedding, the glass brick before the paving of its full back glue treatment, so the back glue process is particularly important, focus on inspection (inspection focus: back glue to the edge uniform not exposed bottom), construction using special tile adhesive construction.

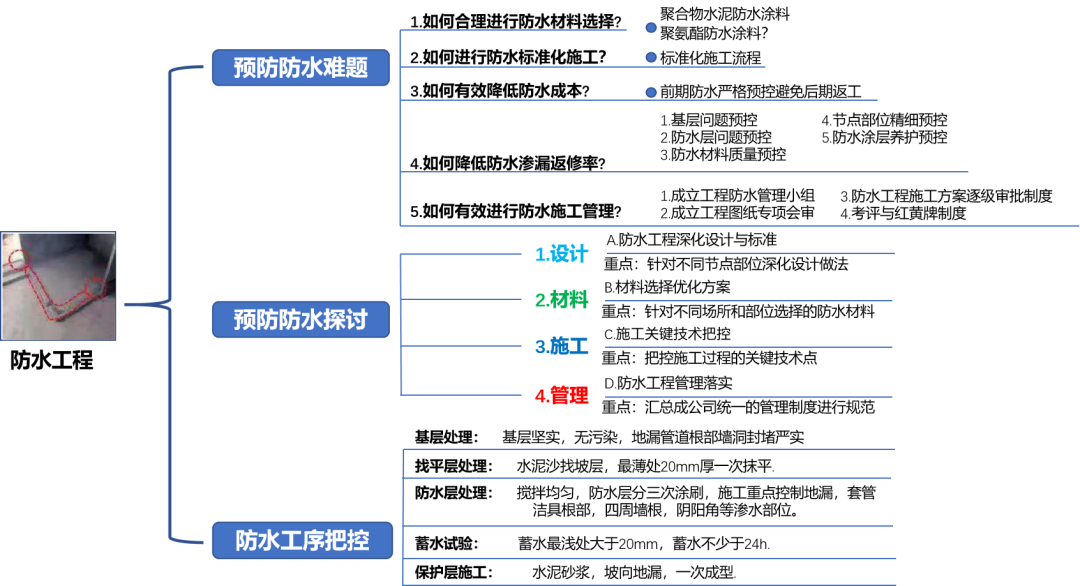

Leak-proof:

Waterproofing process requirements:

(1) Grassroots clean-up; floating dust, mud blocks, impurities around pipe walls, etc.

(2) The angle needs to be done after arc treatment, water does not leak to block.

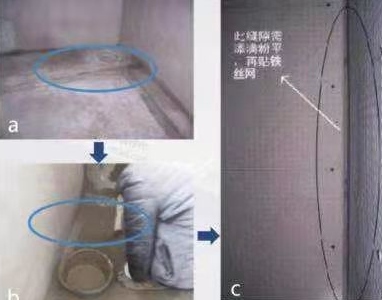

(3) New and old walls sewn wire mesh.

Waterproof control point:

(1) The threshold is waterproof with a water-stopping band brush, waterproofing should be brushed to the dry area (walkway) and turned up 30mm.

(2) The ground leakage position is treated as a funnel.

(3) Shower room water belt.

04

The owner’s sensory requirements for the quality of construction are high, the degree of fine construction is relatively strict, the details are not up to standard, affecting the completion of acceptance

4.1

Fine details

With perfectionist vision with mandatory quantitative indicators, to check and find the quality defects in the field, maximize the quality of practice. Eliminate all defects present on-site one by one to enhance the overall perception.

Door cover edge, wooden floor kick line side of the tight seam display

Switch panel, socket seam, no brush marks around

The tile yang angle of the kitchen bathroom uses arced seams

In the project phased process, is to let us know the phased focus, phase summary, so that in the next stage of adjustment and correction, or a new direction for re-establishment and summary, to find gaps.

Management is not fixed-line, management is changeable, at any time to adjust the way and management program, this is because of people and discusses things, all adjustments are for our ultimate goal, safety, quality, management.