Large-scale commercial projects fine decoration project 14 control points, quickly master the core control system

The following is a large shopping mall project “control points” to do the key explanation.

High-quality implementation – quality control

01.

Develop line requirements

Hardcover repair area Shop glass partition is the mostly circular or irregular arc, so according to the civil survey axis and control points to prepare the “line release guidelines” document, the formulation of unified line principles to ensure the vertical unity of the plane, façade.

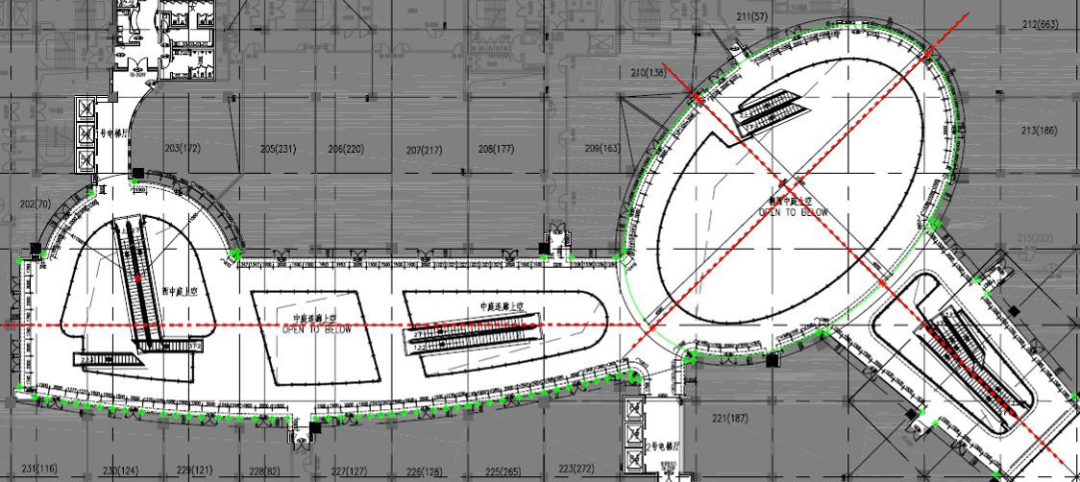

Shop glass line control point and central axis diagram

Ground-based splicing shape and shop arc key control point diagram

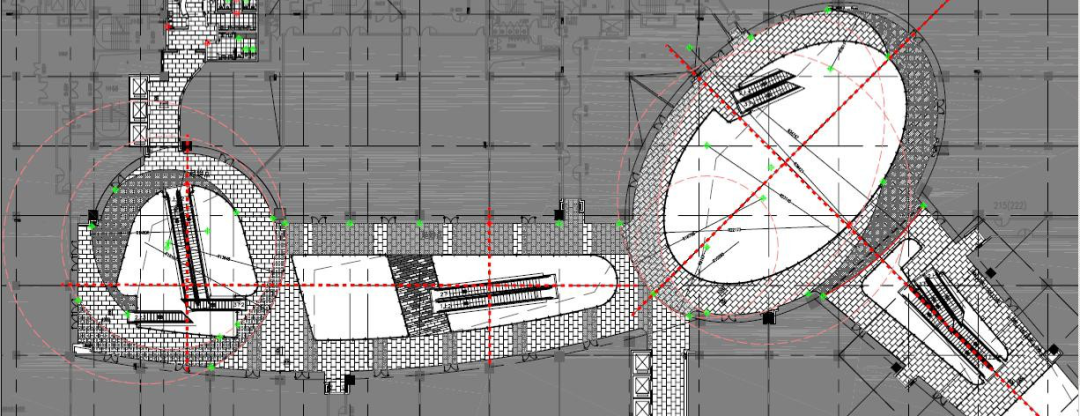

The vertical orientation of the atrium is the focus of our control:

1, in the bidding stage, suggested that the owner will be the vertical direction of the linework with the top section to complete, other review results;

2, each subcontracting construction using unified line drawings, and from the upper level down the hanging line inspection;

3, can be measured by the total package measurement group using the latitude instrument to assist in verifying the verticality of the façade line.

02.

Model first system

Fine decoration project to implement the “model first” system, to model as a large area of construction guidance, the site problems promptly exposed to the model construction stage, for the later construction to provide a basis, but also better control of the site.

The selected areas are densely populated and high customer attention areas, in the fine decoration subcontracting into a large area of work surface with the handover conditions of the stage, the construction between the models.

Note:

1, control glass verticality, flatness;

2, according to the design requirements to leave the seam size uniform, filled with smooth;

3, for the curved glass wall, the door head and the door side of the two pieces of glass are not in the same plane;

03.

Railing works

Glass railing project for the construction of the key areas must meet the requirements of high-quality, about the standard section division of the project, there are currently the following contract evaluation methods, respectively, analysis of the following advantages and disadvantages:

The entire railing project is constructed by one unit:

Advantages:

To ensure the consistency of vertical direction, material quality unity;

Weaknesses:

1, railing construction unit’s progress on the fire acceptance of large, especially in the case of more floor standards, unified coordination difficulty increased;

2, supplier’s product quality as the focus of control.

The entire railing project is constructed by several units:

Advantages:

Railing works are scattered to the construction of each standard section, which can control the progress of materials to the site;

Weaknesses:

1, each bid price is inconsistent, the model quality is different, need to be unified identification;

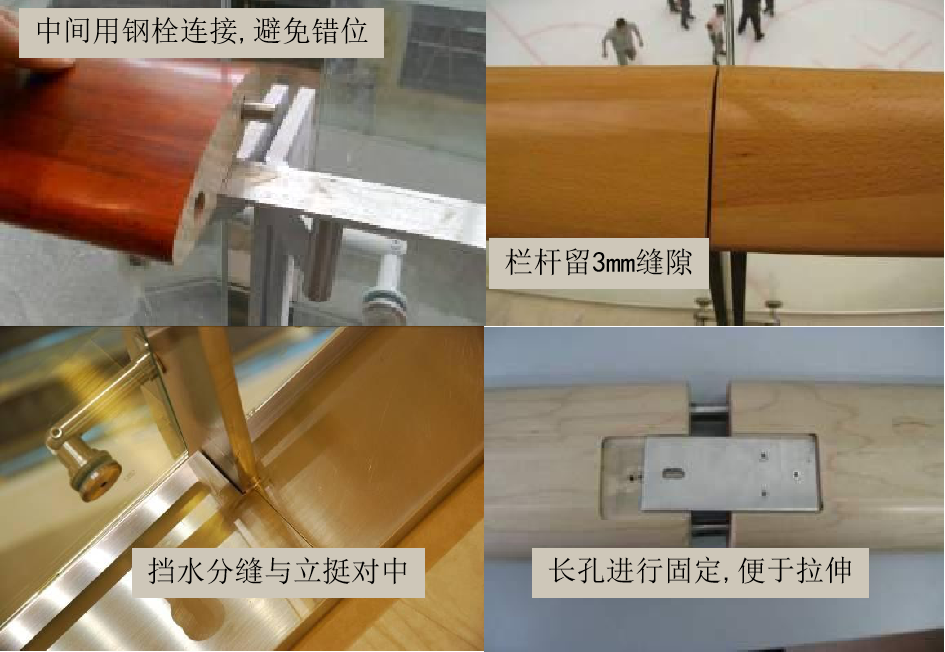

2, the need for a unified vertical direction to block the river stand up positioning points and orientation, each unit unified line, and the scene hanging line, the use of professional measurement group and latitude instrument for auxiliary line;

3, each section has cross-construction site key monitoring, prone to ripping events.

Stand up control points:

1, railing stand up with the direction, arc-type part of the stand-up positioning line map must be strictly controlled, by the general package unified audit;

2, do a good job of pre-buried railings rust removal work, all the selection of hot galvanized products, strictly control the quality of welding, to ensure that welds full;

3, railings stand up the quality, technology must provide a model, and to the manufacturer to examine the production capacity;

4, unified setting of the starting point position of the railing, requiring top-down through the line, and by the upper hanging wire or with the latitude instrument inspection, to ensure that the vertical position of stainless steel stand-up is accurate.

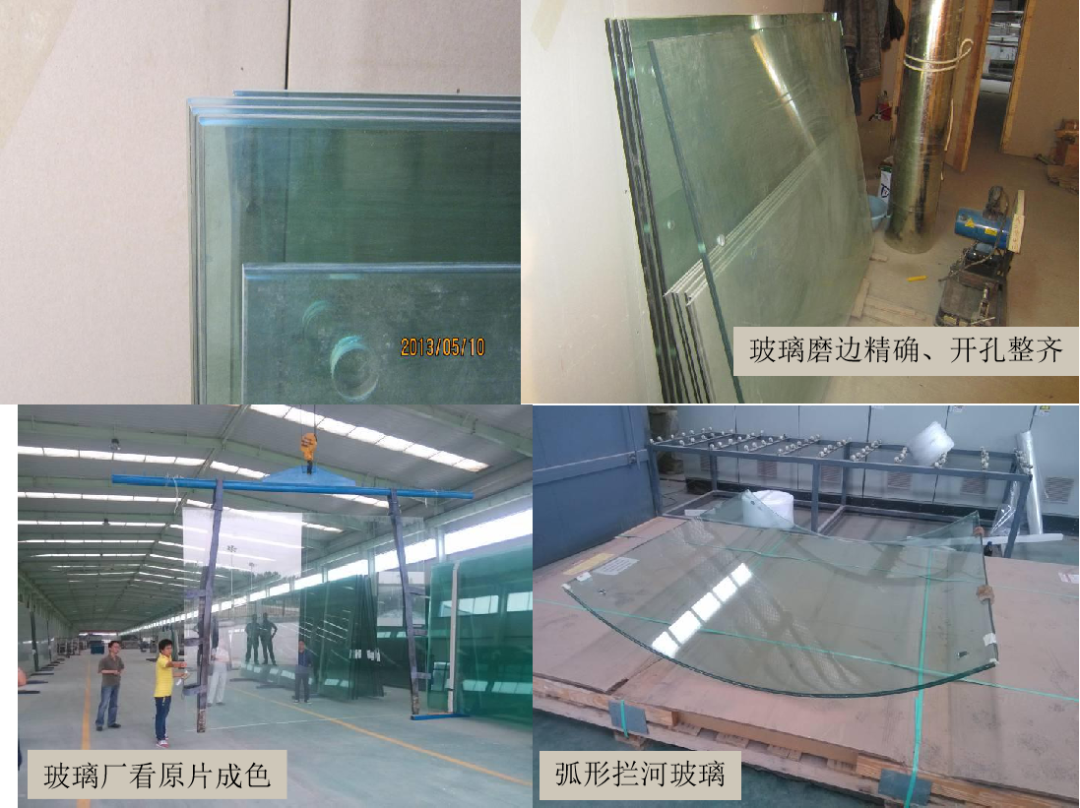

Glass control points:

1, clamp glass four-sided control do not appear high and low difference, especially when the arc glass tempered after the closing of the hole alignment, to prevent the claw installation after uneven stress caused by glass rupture;

2, the use of large factories to produce glass originals, inspection and selection of strong glass deep processing plant, and manufacturers processing quality requirements, strict factory and entry acceptance link;

3, fine grinding four sides, surface no scratches, collapse edge;

Railing material: stainless steel handrail simple atmosphere, easy to construct and maintain, slightly low-grade, the northern winter and spring festival should produce “static electricity”, Zhengzhou dry weather choose wooden armrests.

Water-blocking materials: stainless steel processing is simple, construction is convenient, most of the choice of stainless steel materials;

The following image shows how to handle the four corners of the river:

04.

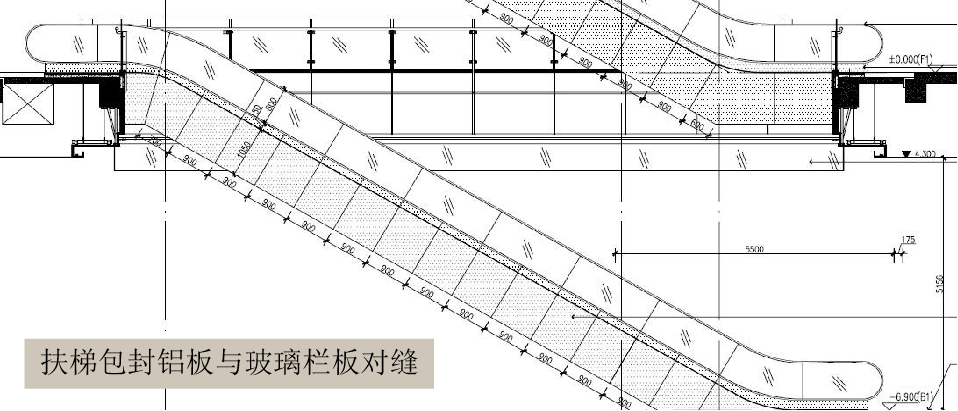

Escalator encasing control points

Atrium escalators are an important component and an important channel for customers to shop, so they should be controlled:

1, fine decoration subcontracting for the middle line, edge line, escalator at both ends of the use of plant-based way to complete the surface elevation;

2, escalator lifting should be completed before scaffolding in place, because the ladder envelope aluminum plate requirements and glass railings to the seam, the need for ladder professional ejection of glass dividers on steel beams.

05.

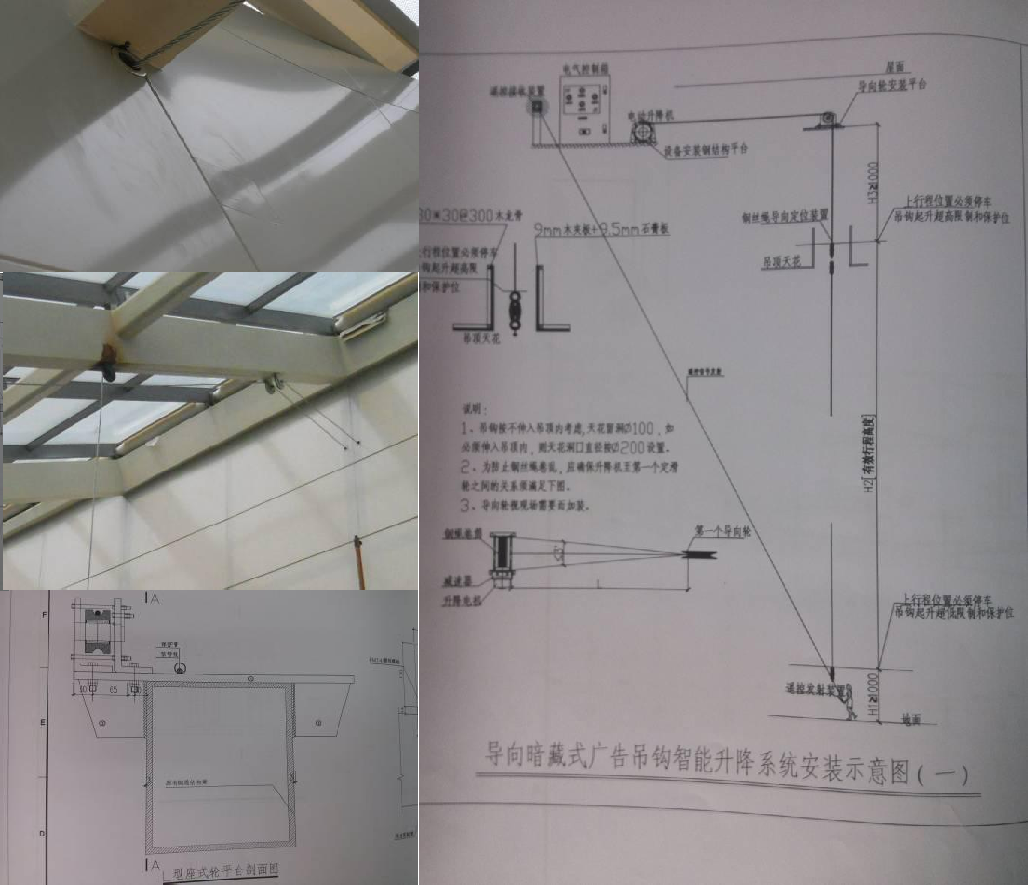

Electric hook attention point

Key points of control:

1, hook wire rope free swing angle is less than 3 degrees, the active travel must be controlled in a hidden position, pay attention to avoid the impact of the ceiling internal equipment, in the line position plus sheave change direction;

2, sheave bracket and curtain wall, the steel structure of the cooperation, the process should be arranged in the steel structure to complete the finish of finishing treatment and window glass installation before;

3, insert the deepening design in advance, optimize the selection and position of the coiling machine, the power supply, control box installation position is hidden;

06.

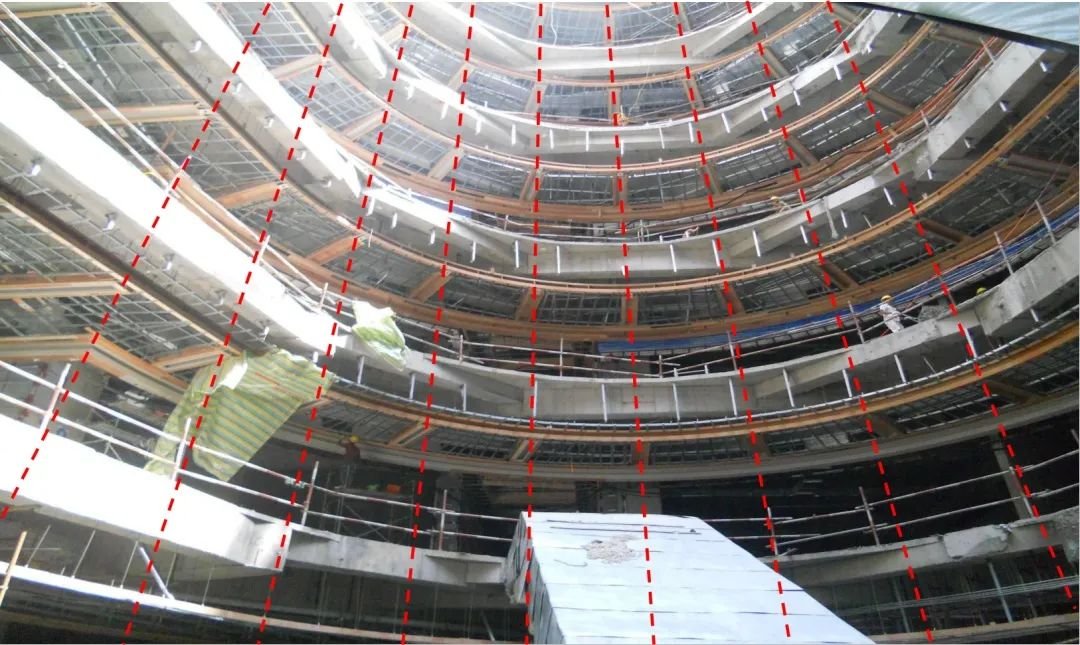

Soft film smallpox structure construction improvement

Soft film B-grade soft film smallpox material: nano-PVC.

Features: clean surface, better luminescence effect, low cost, easy construction, low fire level;

Class B fire-resistant soft film smallpox adapts to temperature: -25 to 45 degrees C.

Soft film Class A fireproof soft film smallpox material: special treatment of fiberglass and fluorine resin and velum fiber.

Features: clean surface, better luminous effect, higher cost, than B-grade film per square meter increase of nearly 1800 yuan cost, high fire level;

Class A fire-resistant soft film smallpox adapts to temperature:-50 to 100 degrees C.

Soft-film smallpox contrasts with ordinary smallpox

Soft film smallpox if the construction design and construction of quality control are not good, in practical application is more prone to problems, installation of about half a year will appear, as shown in the picture of the problem.

In response to such problems, the soft film structure is improved during the implementation phase of the sample area:

1, increase the opening device, easy access to the upper lamp;

2, lighting arrangement rules, average spacing, lamp is-head hooking;

3, the lightbox internal space height control between 250-300mm;

4. Consider transformer bypass to avoid shadows.

07.

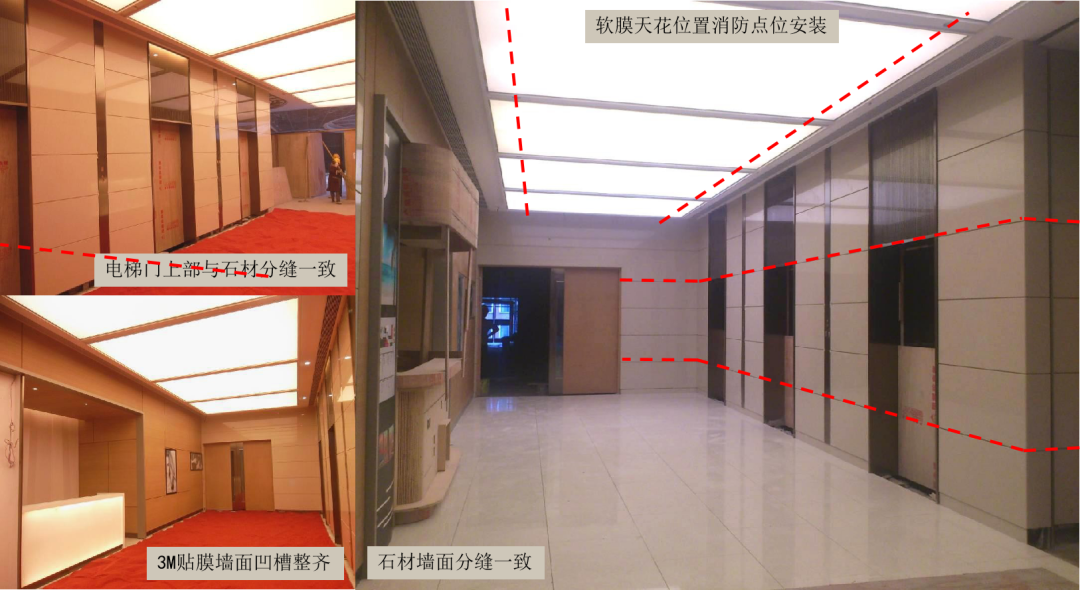

Fire-resistant curtain closing

At present, the overall construction level of the fire curtain construction unit is not high, roll curtain due to scrolls, curtains, and other structural compositions led to the fire curtain accuracy is not high, each lift after the bottom plate plane will change, so the fire curtain bottom plate closing is somewhat unattrespite the problem, which is a major problem that the fine decoration project needs to overcome.

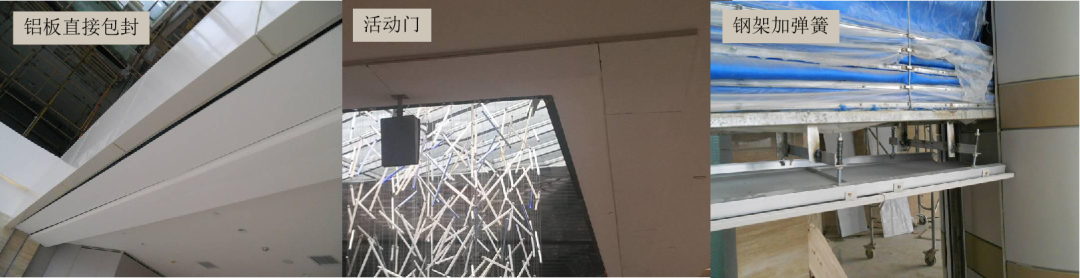

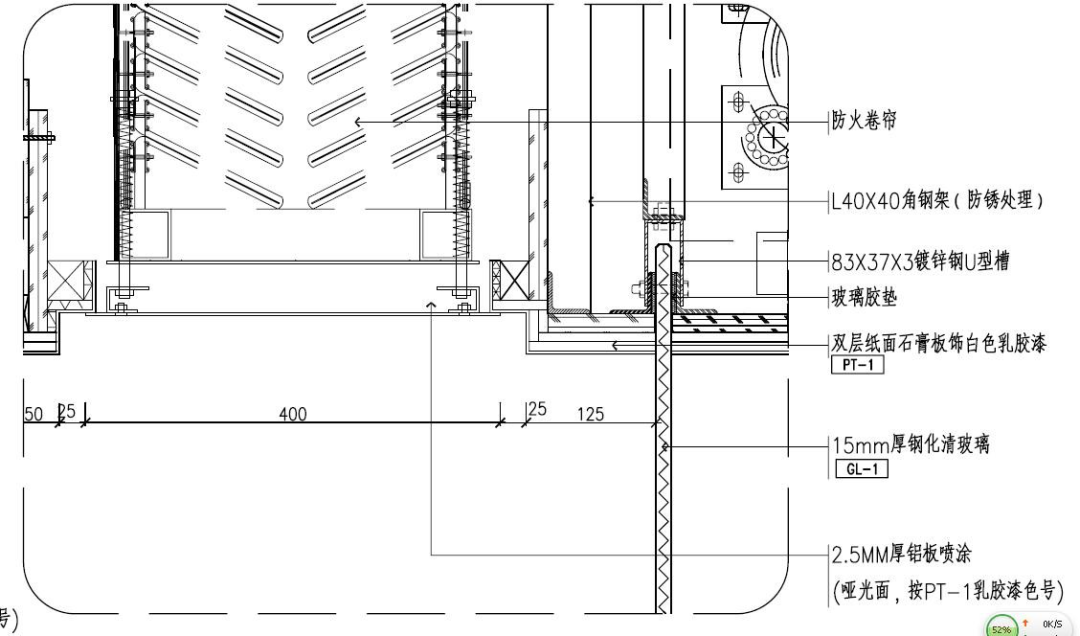

Because of the common quality problems of the curtain closing, the existing structure is improved, and the groove is added based on the curtain closing structure, so that the gap between the aluminum plate and the gypsum plate is closed in the groove, weakening the gap in the closing, and ensuring the external visual beauty.

A large sample of the closing at the bottom of the curtain