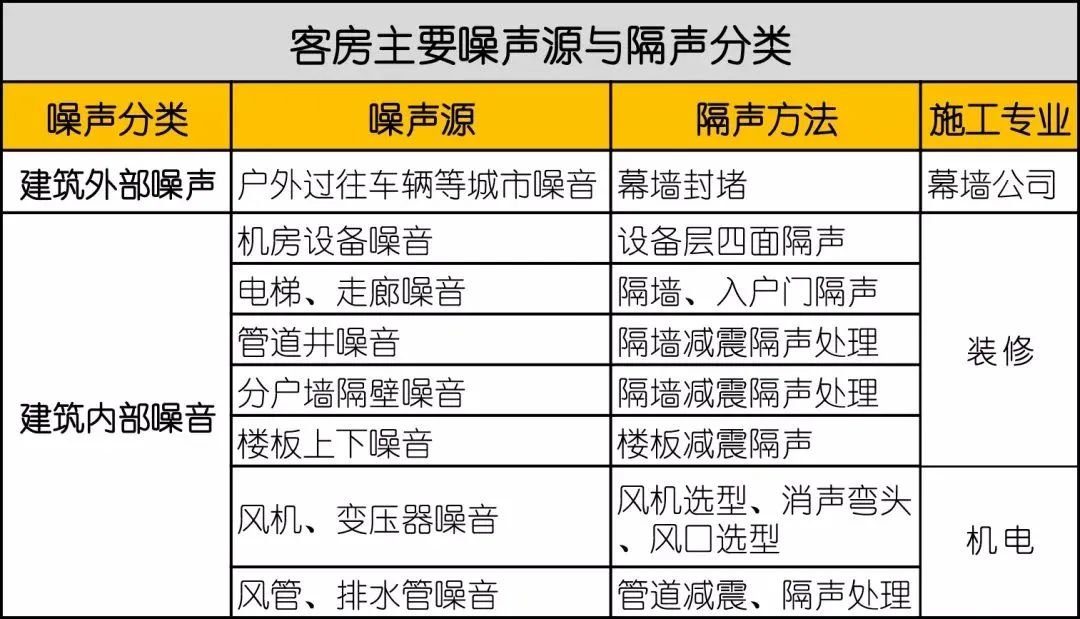

Acoustic soundproofing construction scheme for five-star hotel rooms

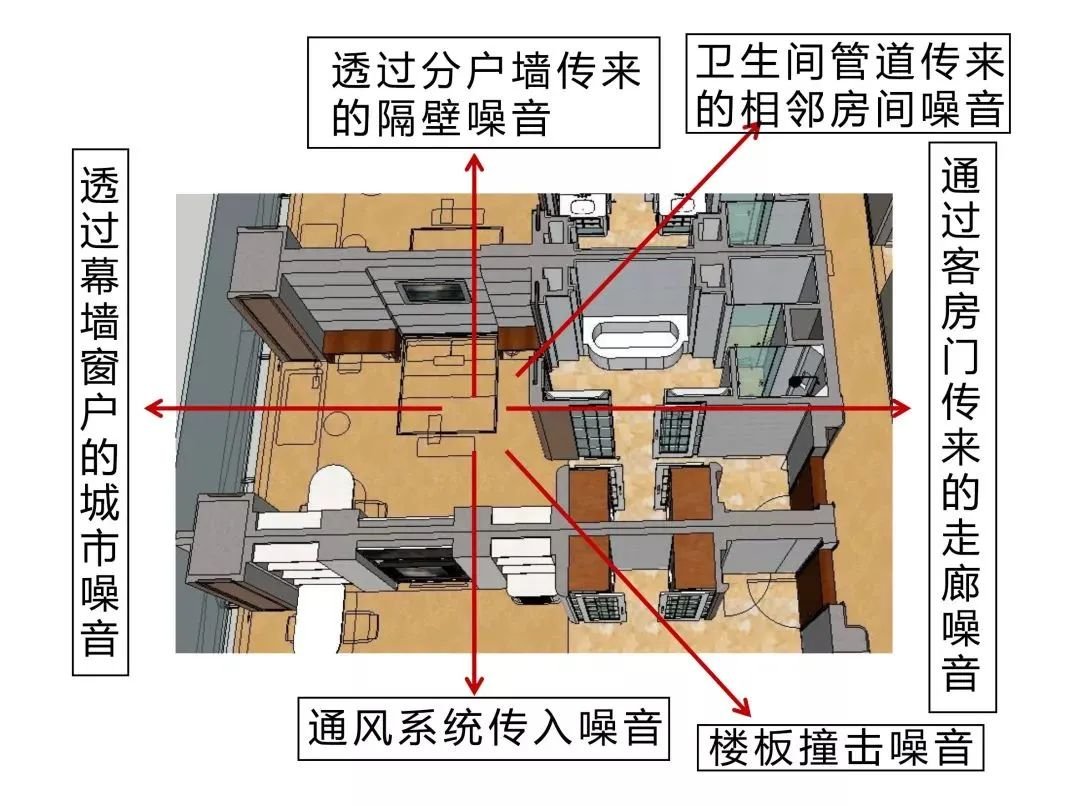

A five-star hotel on the room sound insulation requirements are very high, construction requirements are also very detailed, this issue we share with you five-star hotel room soundproofing construction program, integration of relevant acoustic design specifications, and combined with the actual situation on the construction site, to provide a reference for construction experience.

For the above 8 room noise sources, soundproofing schemes and measures are detailed below:

01

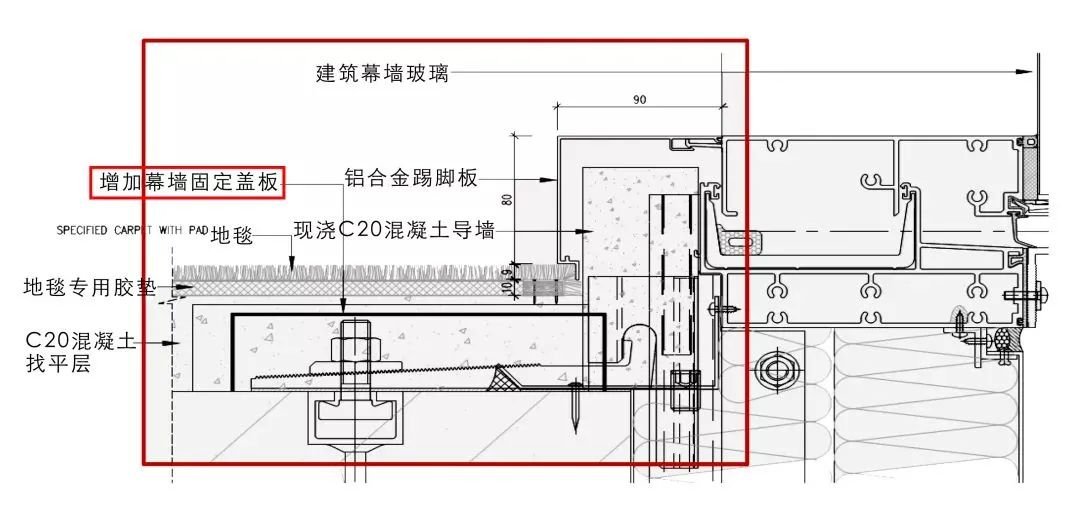

Measures to be taken in the area against the curtain wall

1.1

Blocked between curtain walls

Curtain wall fixed cover sulfate sulfate s/he concrete s/he carpet-specific mats s/carpets

Blocking node between curtain wall floors

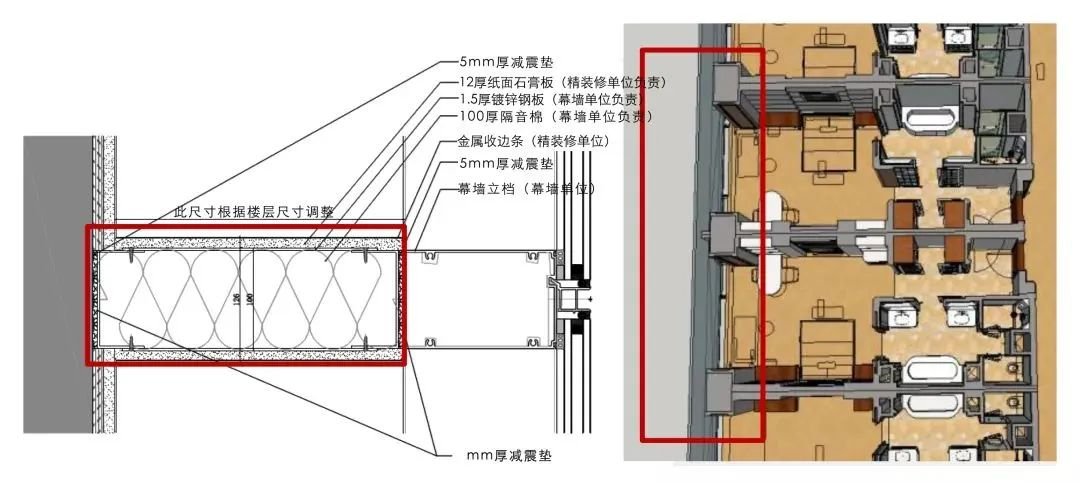

1.2

Soundproofing and damping practices on the partition wall against the curtain wall

100 Keel smoldering cotton (100kg/ m3) s galvanized steel plate (1.5mm x 2)s gypsum plate (). 12mm*2)

The wall-blocking practices that connect to the curtain wall node diagram

02

Decorative soundproofing and damping measures

2.1

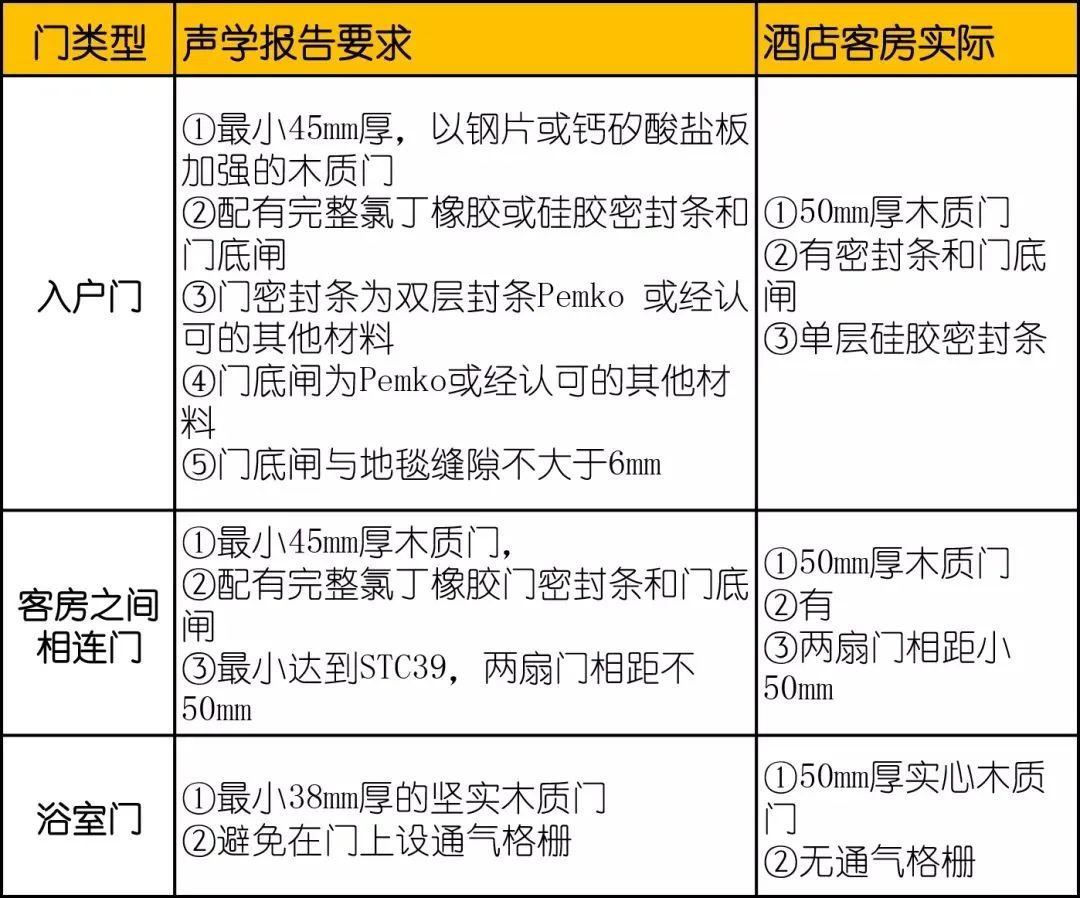

soundproofing of the door

2.2

The practice of soundproofing and damping of walls

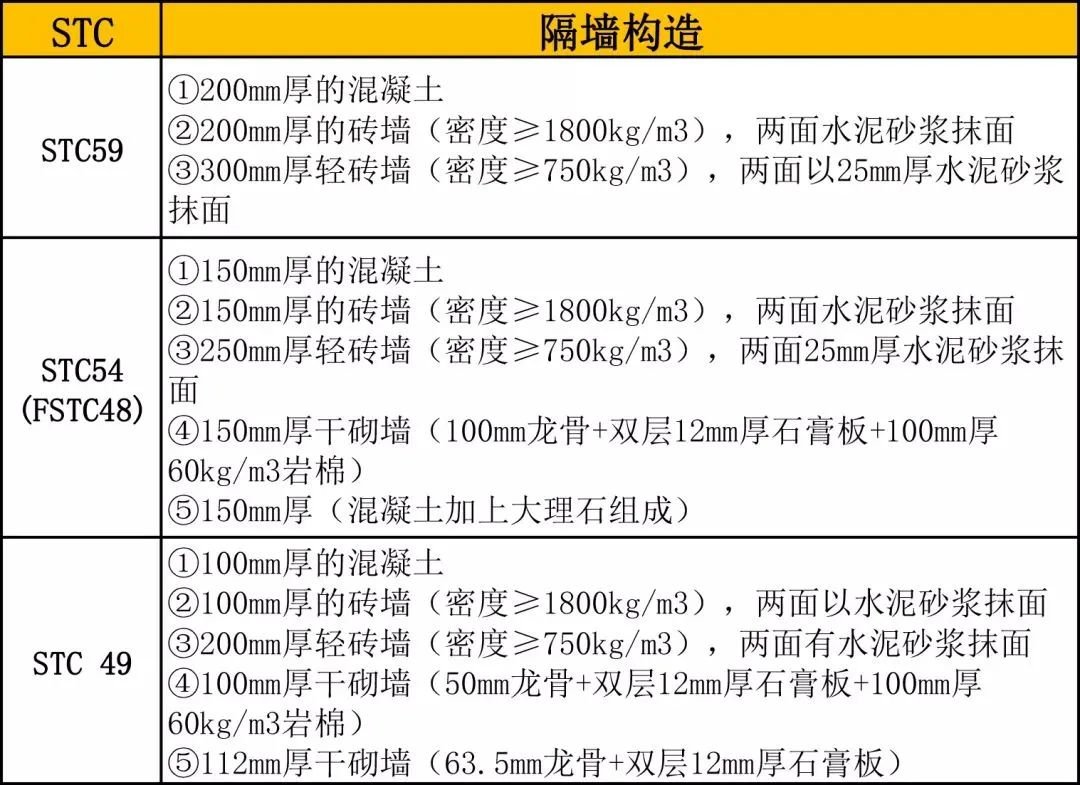

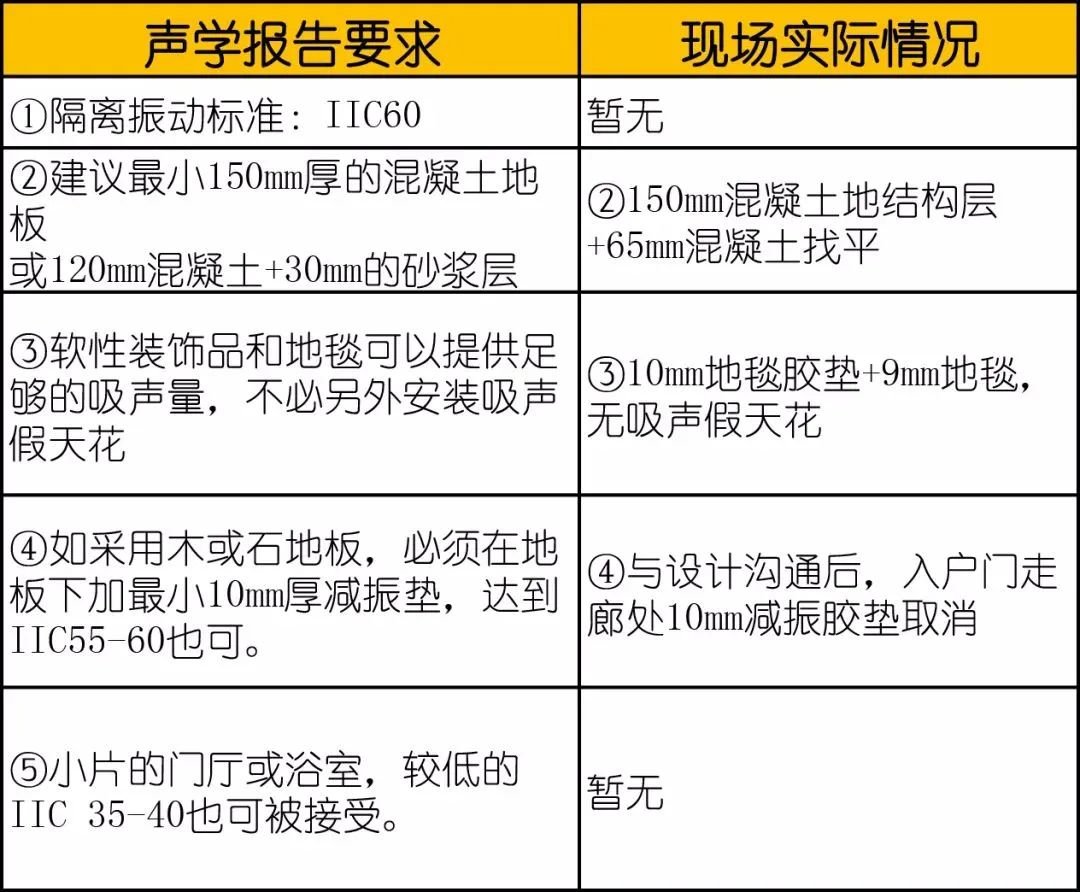

STC: Minimum noise transmission level standard for rooms. Five-star hotels generally require STC standards of 39 to 60 rooms.

2.3

Specific wall-blocking practices

(1) Household Wall Practice Node Construction:12mm gypsum board s5 s75mm(60kg/m3)rock wool s2 layers

Hotel rooms are divided into wall nodes, click to view the larger picture

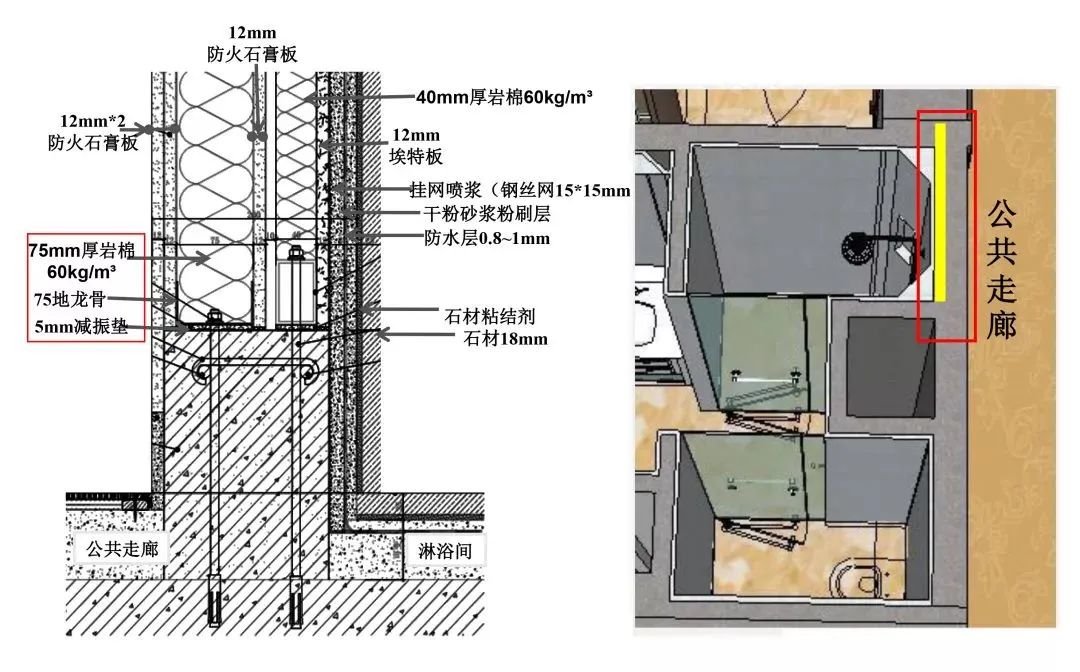

(2) Showers are separated from public corridor walls

The public corridor is separated from the shower area by a wall node, click to see the larger picture

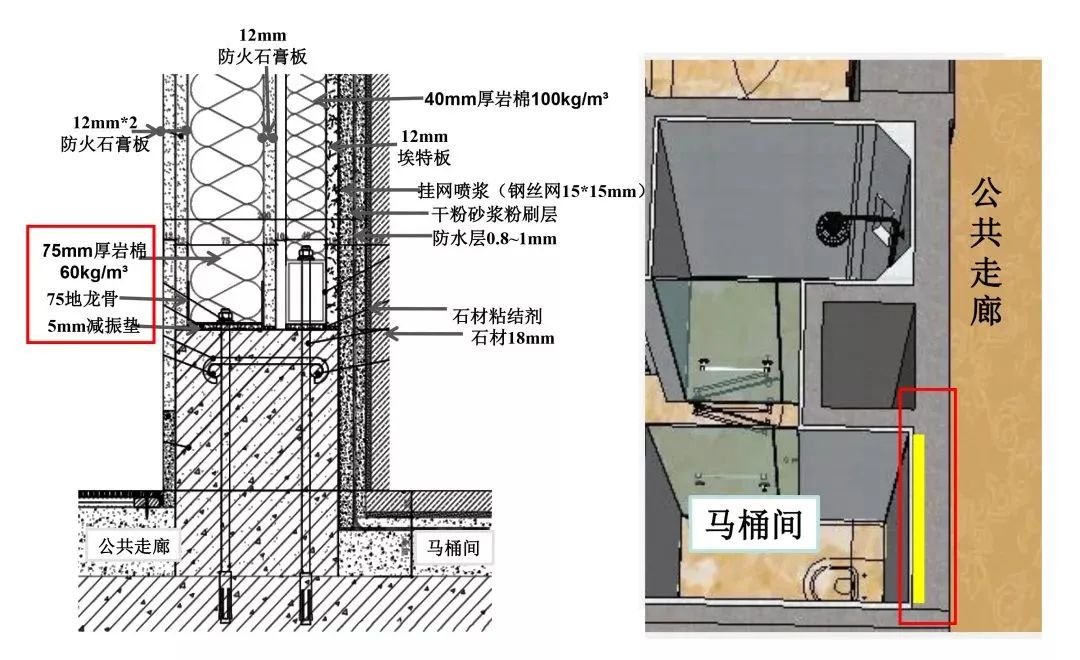

(3) Toilet room and public corridor partition wall

For the public corridor and toilet spacer wall node, click to see the larger picture

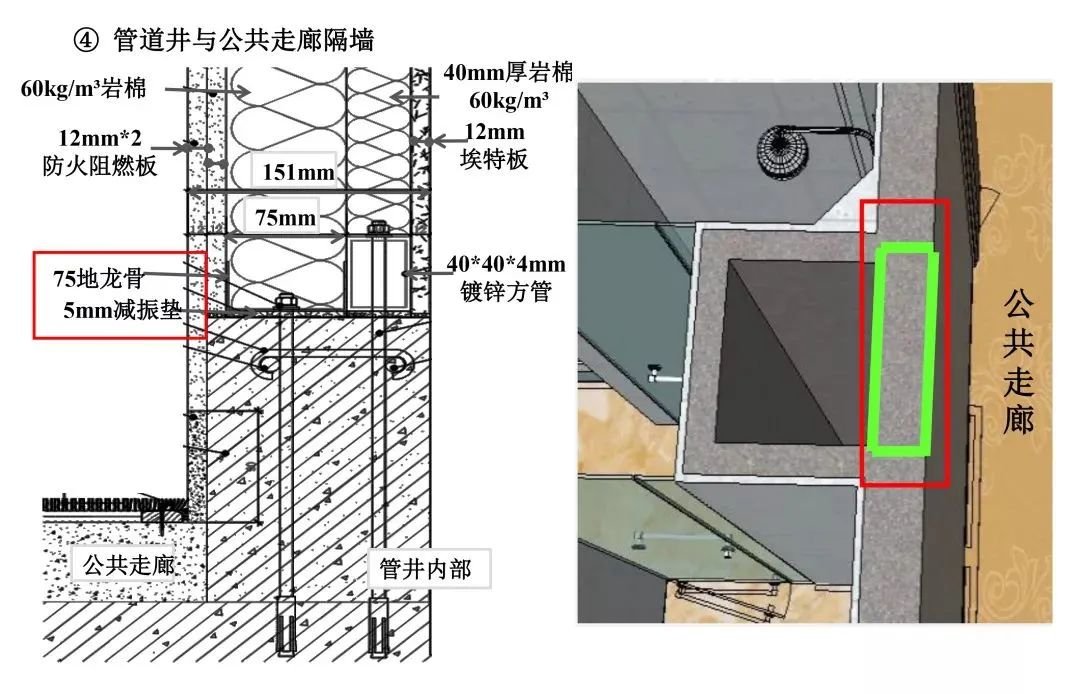

(4) Pipe wells and public corridor walls

For the public corridor and pipe well wall node, click to view the larger picture

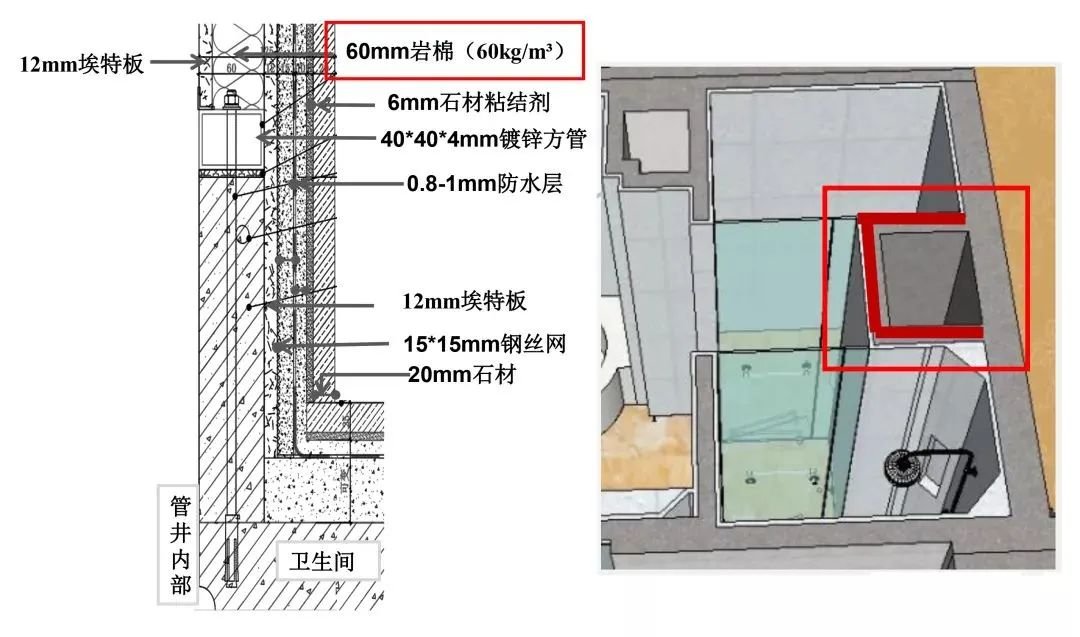

(5)Pipe well and indoor partition wall

Pipe well and indoor partition wall node, click to view the large picture

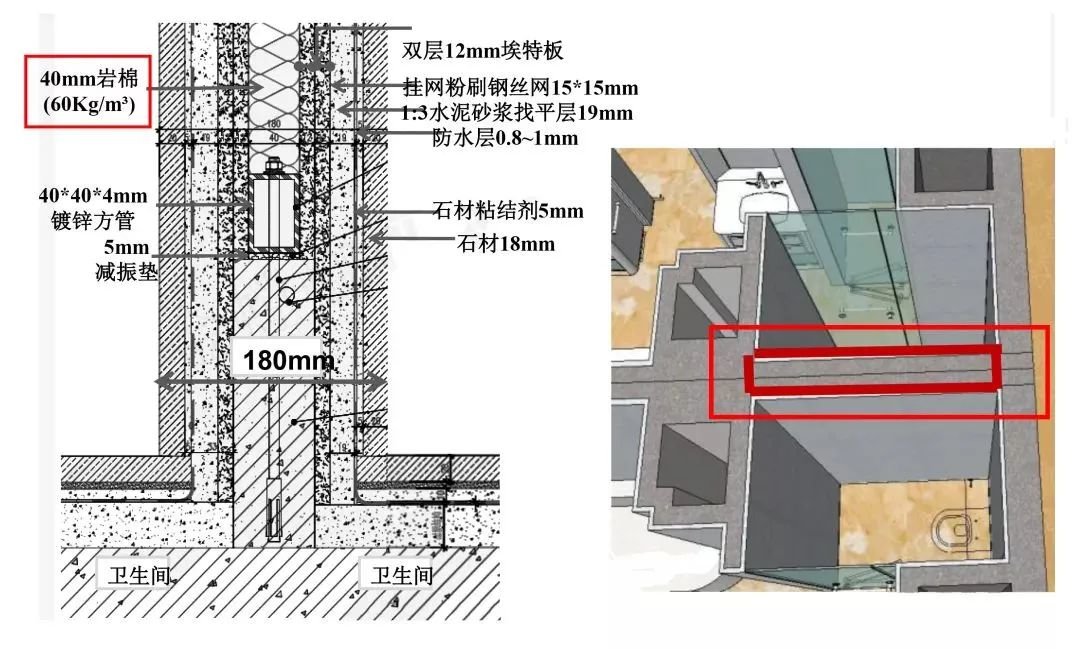

(6)Adjacent room bathroom and sanitary space wall

Room adjacent sanitary spacer wall node, click to view the large picture

2.4

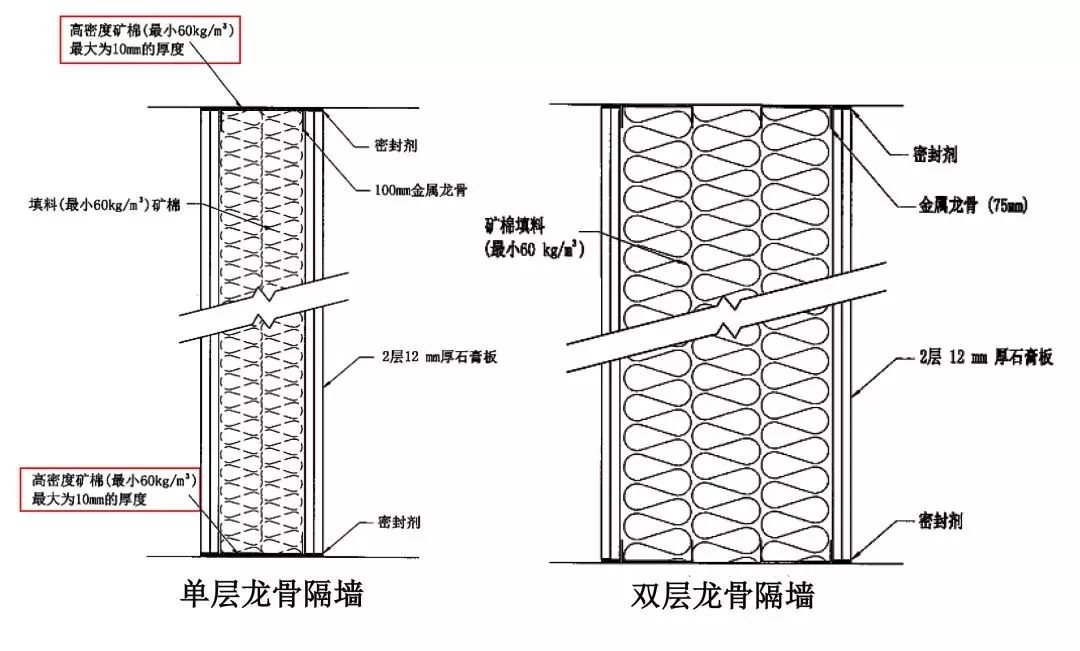

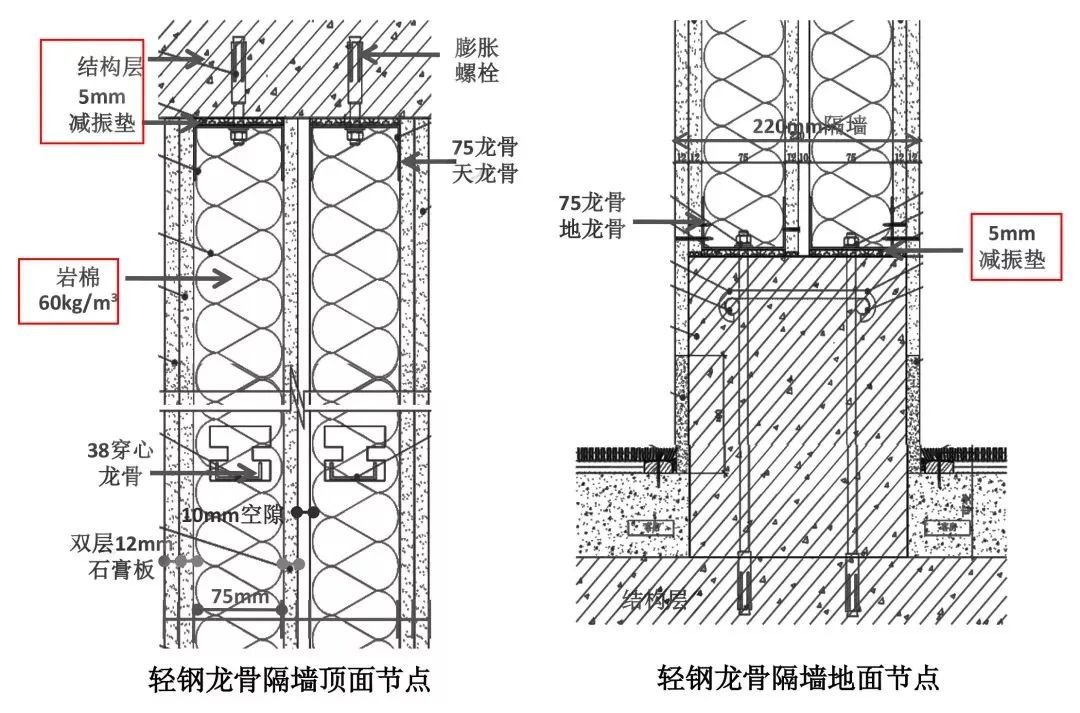

Construction practices for wall shock absorption (details)

The 5mm rubber mat is temporarily fixed to the keel by the used paper

The keel is sealed by sealant after it is installed and secured

2.5

Pipe well walling practice details

Fixed pipe well square steel away from the guide wall, sealing the plate does not touch the plate surface, to prevent pipe vibration to drive the wall gypsum board vibration

2.6

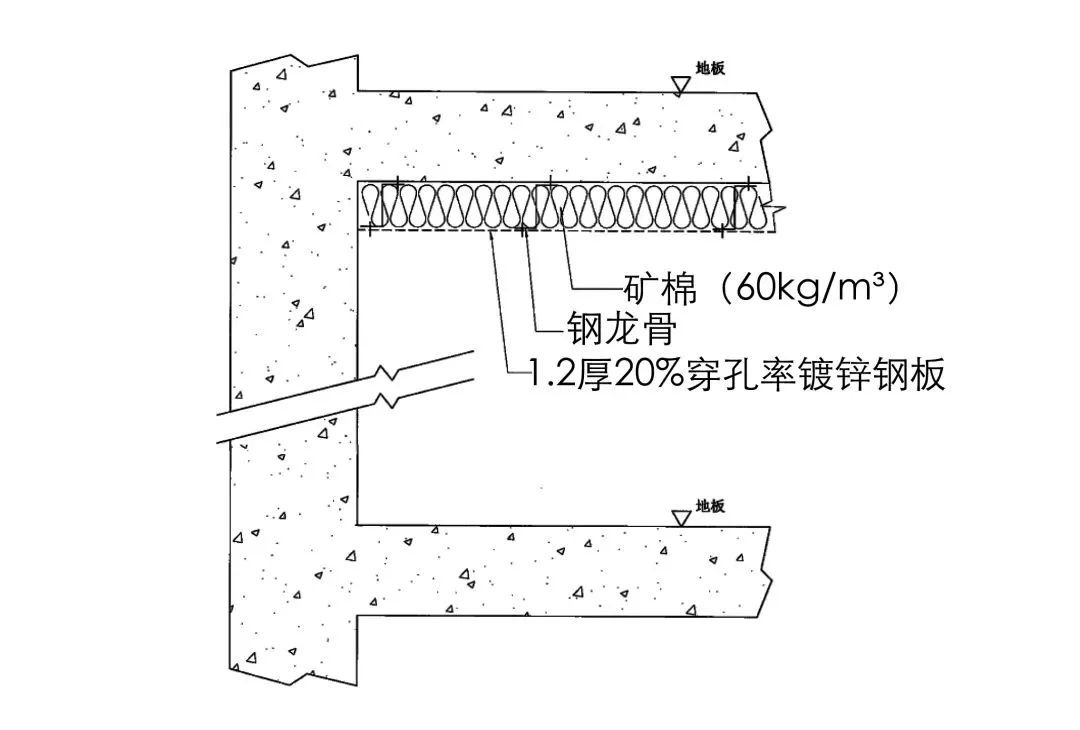

Smallpox sound insulation practice requirements

Ceiling practices are consistent with acoustic reports providing sound-absorbing ceiling construction, with a minimum of 150mm thick concrete on the ceiling and a minimum of 50mm thick sound-absorbing padding.

2.7

Ground sound insulation practices and requirements

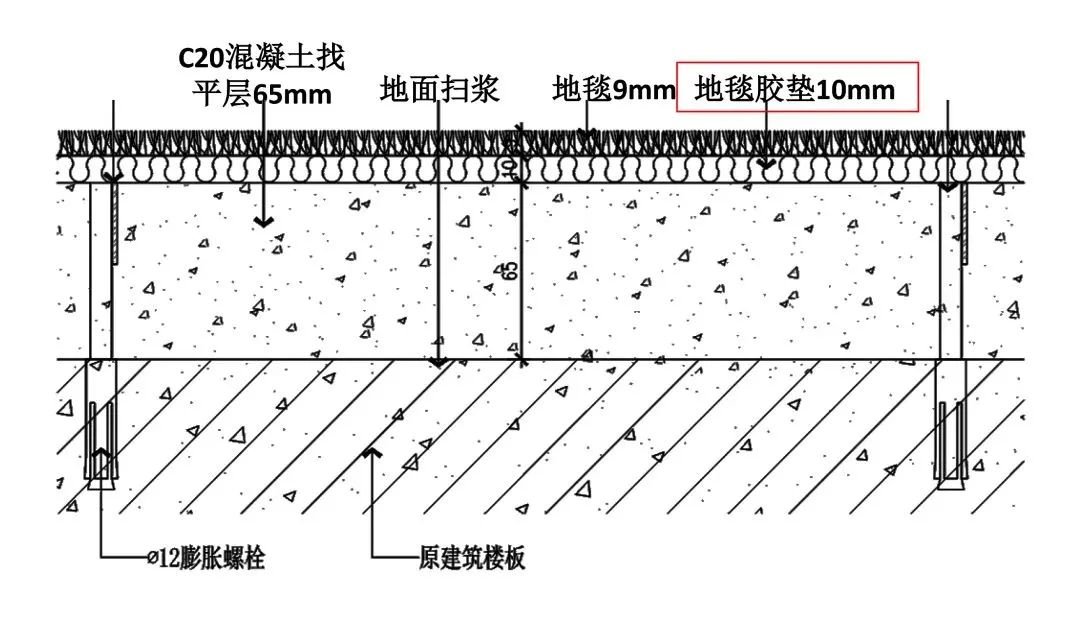

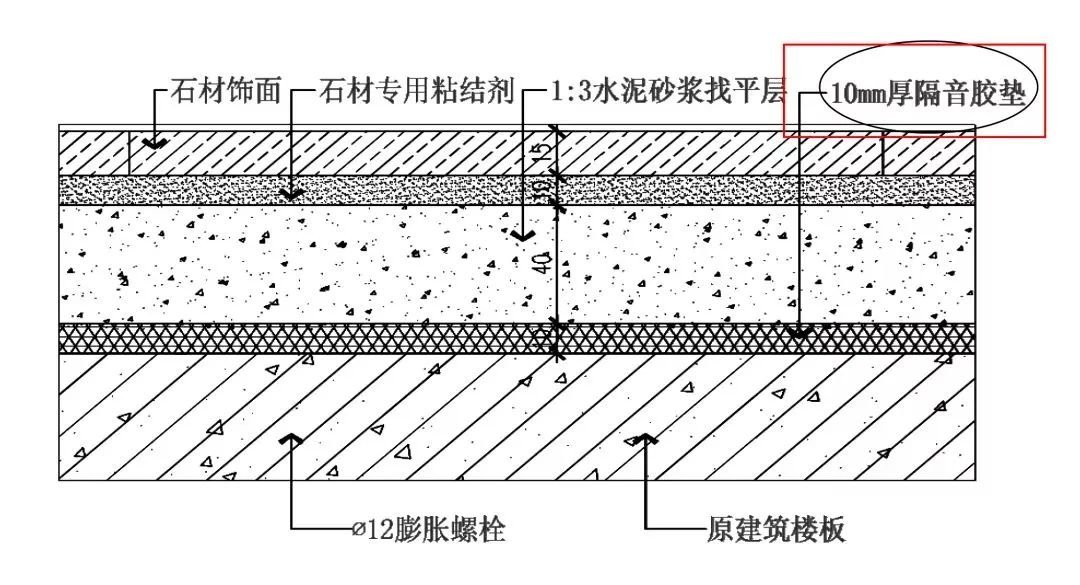

(1)Interior ground practices in the room:65mm concrete leveling s10mm carpet mats s9mm carpets

(2)Into the corridor: find a flat layer of soundproofing mats and stone Four Seasons Hotel Entry Corridor Ground Practice:40mm Cement Mortar Flattening and Stone

03

Cooperate with professional sound insulation and shock absorption measures

3.1

Electromechanical sound insulation and vibration reduction practices

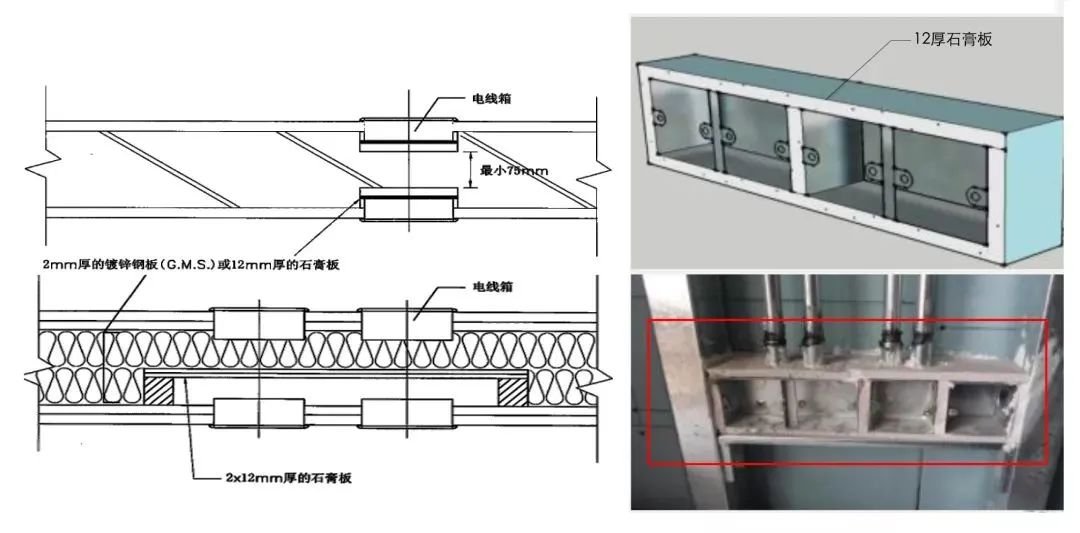

(1) Sound insulation practices for switch and socket back boxes Acoustic reporting requirements The acoustic report states: Sound insulation is required when the distance between the two bottom boxes is less than 150mm. The sound insulation practice is as follows:

- Two-back boxes are less than 150mmapart, greater than 75mm, back-to-back sockets, can be used 2mm thick galvanized steel plate or 12mm thick gypsum board to cover the back box around

- When the four back boxes are adjacent, the 2 layers of 12mm thick gypsum plate are used to cover the back box around tianjin Four Seasons with 12mm gypsum board cladding.

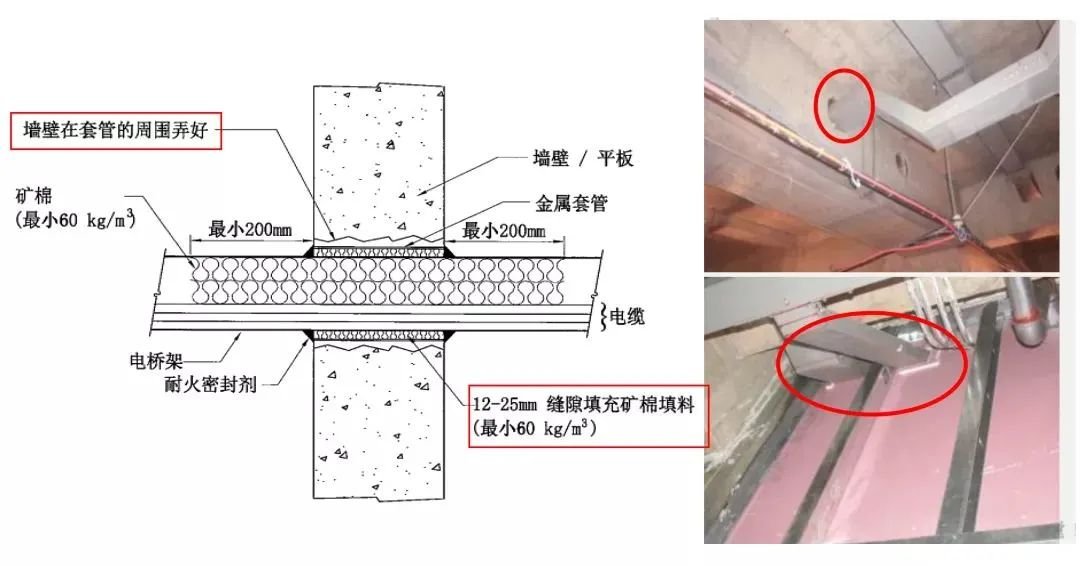

(2) Soundproofing practices through wall bridges The gap between the bridge and the structural wall is sealed:

(1) Acoustic reporting requires a minimum of 60kg/m3 of rock wool to be filled around the crevices and sealed with fire-resistant sealant at the end;

(2) Tianjin Four Seasons site with 60kg/m3 rock wool filled gaps and closed with gypsum board.

3.2

Sound insulation and vibration reduction in the air conditioning system

(1) Fan coil: When the fan coil is installed, a spring gasket connection should be used between the boom and the winding coil to reduce the noise caused by vibration when the winding coil is running.

On-site lifting, due to ceiling height limits, can not be added spring gaskets, so in the boom and wind plate connection to add rubber cushions to reduce vibration noise.

(2) Silence elbow: When the fan coil is installed, a spring gasket connection should be used between the boom and the wind plate to reduce the noise caused by vibration when the wind turbine is running.

The silence elbow and the fan coil are softly connected by aluminum foil, and the construction of the silence elbow can also absorb sound and reduce noise.

3.3

HVAC sound-absorbing practices

(1) Duct sound insulation treatment

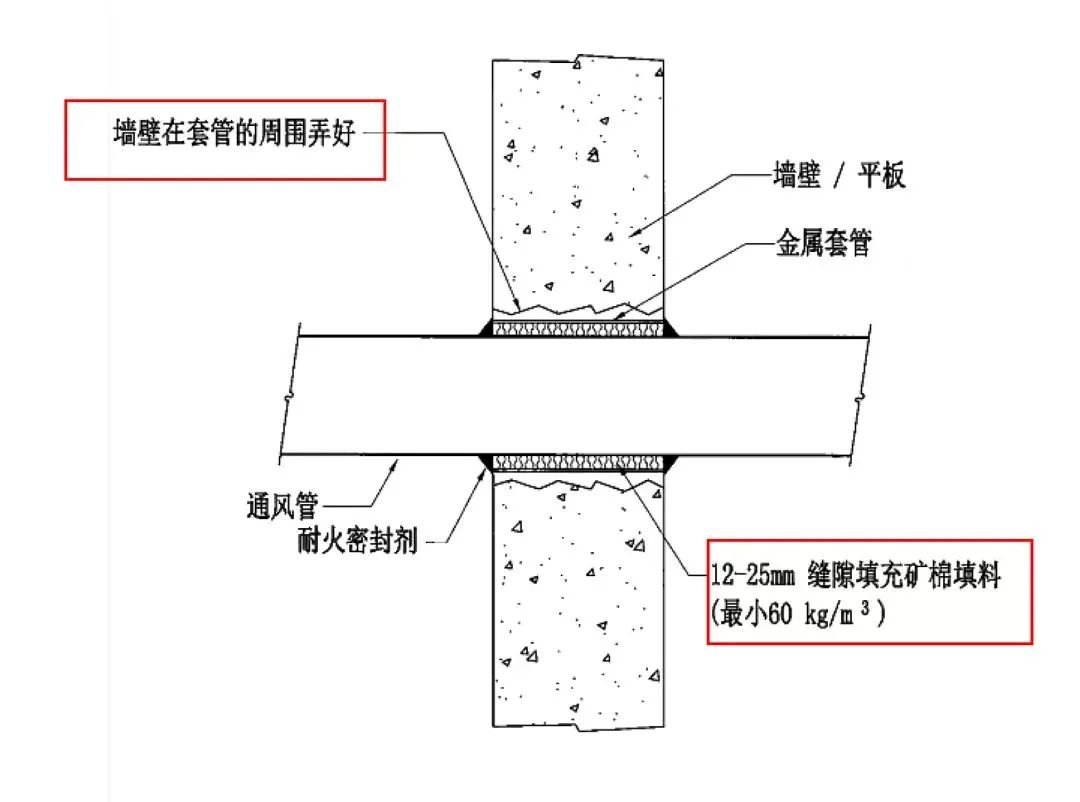

The duct pierces the wall soundproofing node

- A minimum of 25 mm thick sound padding should be installed on all low-speed gas supply pipes and fittings.

- To install pipe soundproof linings, the material can be neoprene rubber or ethylene-coated fiberglass.

-

The minimum spacing within the inlet and outlet tubes of each low-pressure air treatment unit is 4570mm.

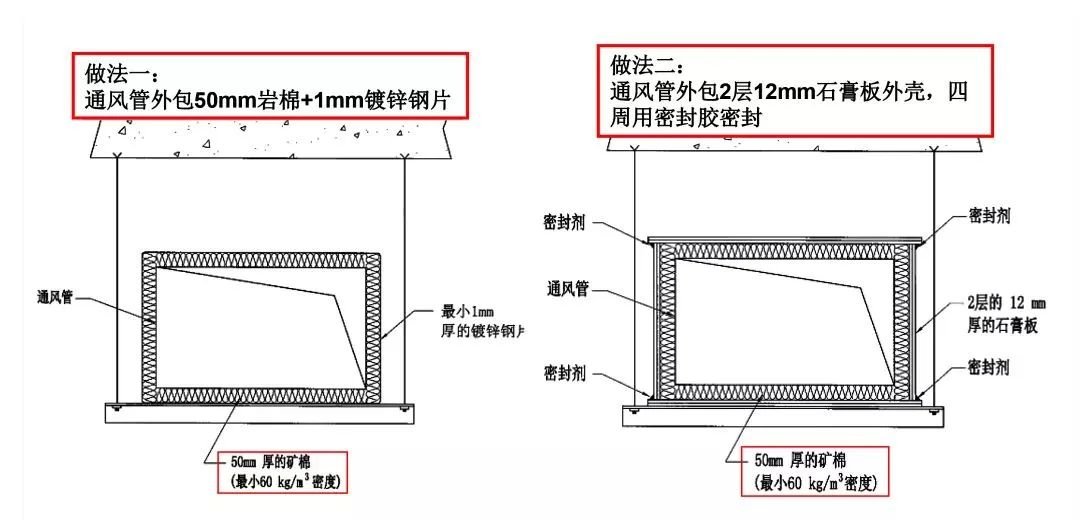

(2) Acoustic report requires duct coat sound insulation noise reduction practices:

Duct soundproofing node

3.4

Water-resistant nodes for sound insulation and damping measures in the water supply and drainage pipes

(1) All lines should be hung with elastic booms. The boom should be a combination of shear-resistant rubber and spring boom

(2) All through the wall should be left 25mm gap, with soundproofing seam material (or non-rigid flame retardant seal material) for insulation and sealing.

(3) The vibration break at the perforation of the pipe can be achieved by installing a larger tube sleeve, and the gap between the pipe and the pipe sleeve is filled with glass cotton. There must be a minimum 12mm gap between the pipe and the sleeve.

(4) The vibration separator between the pipe and the structure is recommended for the installation of steel insulation springs with a minimum 25mm static deflection. Any support for all water pipes associated with the pump must also be accompanied by a damping spring with a minimum 25mm static deflection.