80% of project problems are always on these old issues? Master 3 key points and do a good job of project re-entry!

And through the pre-planning, the whole process of project implementation of sand disk projection, understand the project difficulties, do a good job of project technology, in the actual implementation, adhere to the second and third business planning, to ensure that the project expected goals. Final project completed, the project department full summary of experience and gain and loss, form a written report, will be a good experience in the company-wide promotion, these are we very much need to learn from large companies.

Recommended to learn from large-scale installation enterprises pre-project planning

After learning the needs of several decorative peers for project construction planning, today to a model room project as an example, and you comb the important link of project construction management, to help you do a good job of project experience summary!

Objective: The model room stage reflects my department for the hotel construction management and professional, hope that the construction of the model room can win the big bid. The experiment of assembly construction, find out the rhythm point of assembly construction and which parts are suitable for assembly construction, summarize assembly construction.

01

Drawings are difficult to analyze and deepen the design

1.1

Deepen the list, design answers

1.2

Deepen the case study

1, steel frame partition wall deepening case

The strict control of the thickness of the paint layer, as far as possible to minimize the thickness of the wall. The new door wardrobe scheme adds features (increased storage space for clothes, moved the lockbox to the left platform, and added ironing rack functionality).

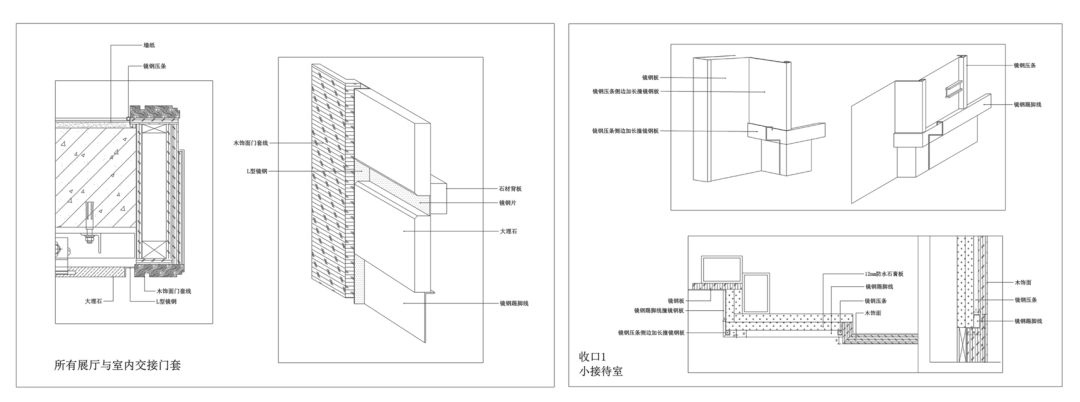

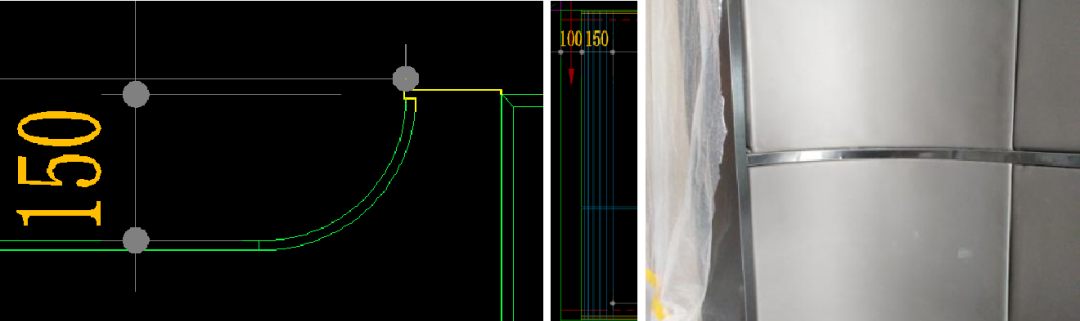

2, stainless steel and hard bag closing

The leather hard pack and stainless steel flatness can be well controlled by colliding with the “several” stainless steel. The figure on the right shows the practice of stopping the water barrier beams.

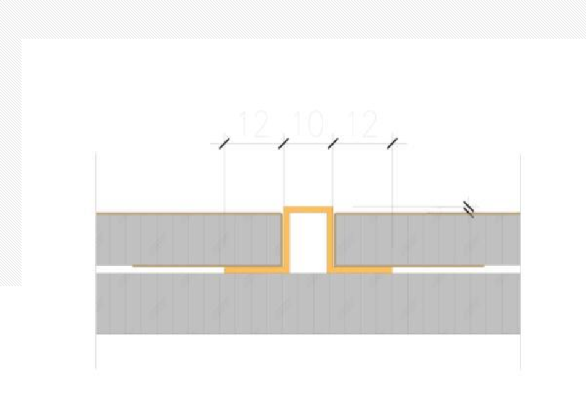

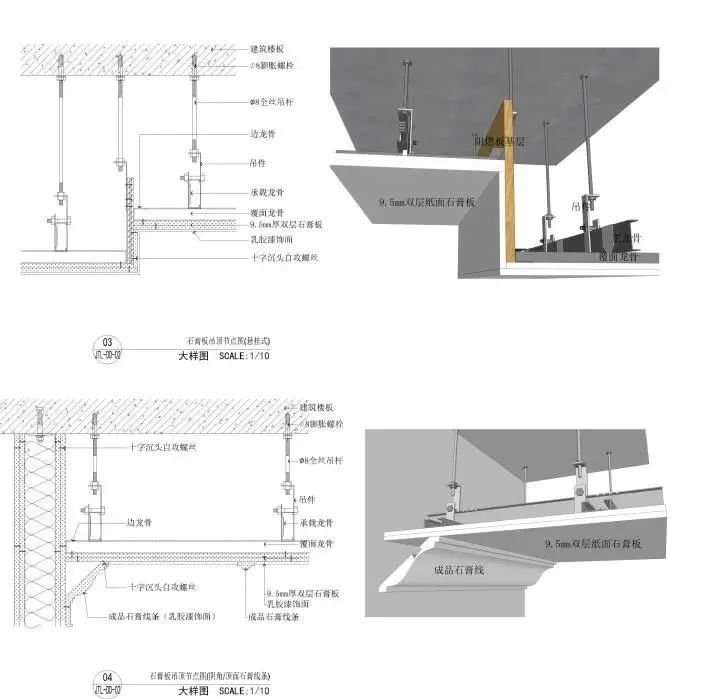

3, important nodes (3D drawing).

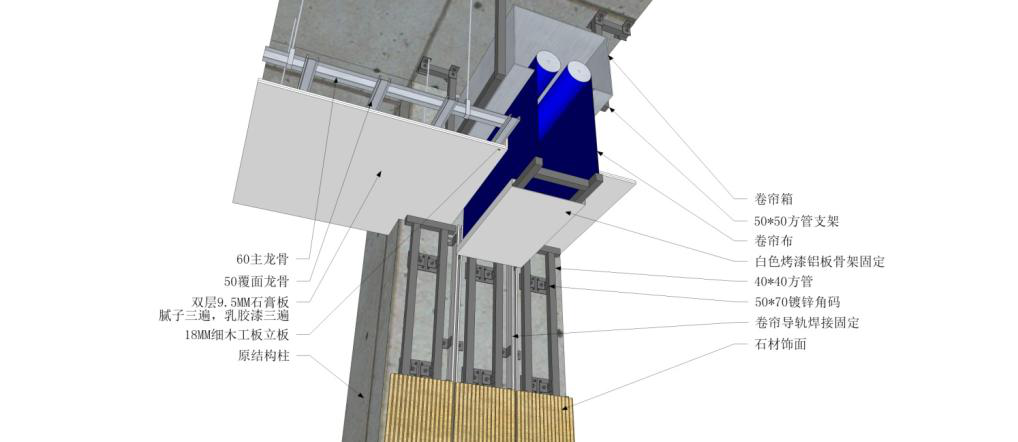

Gypsum board ceiling node diagram

Anti-support process node diagram

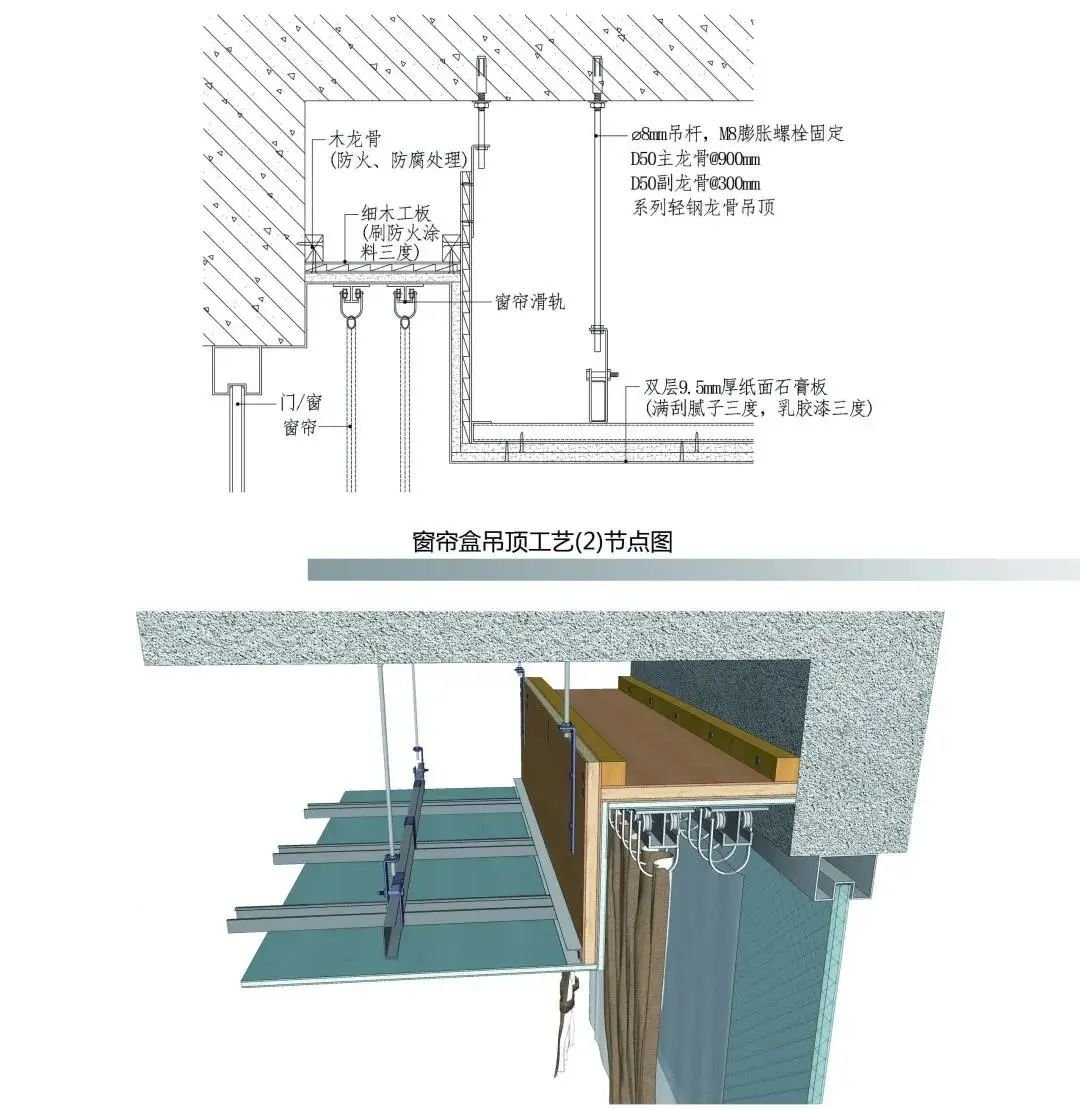

Curtain box ceiling process

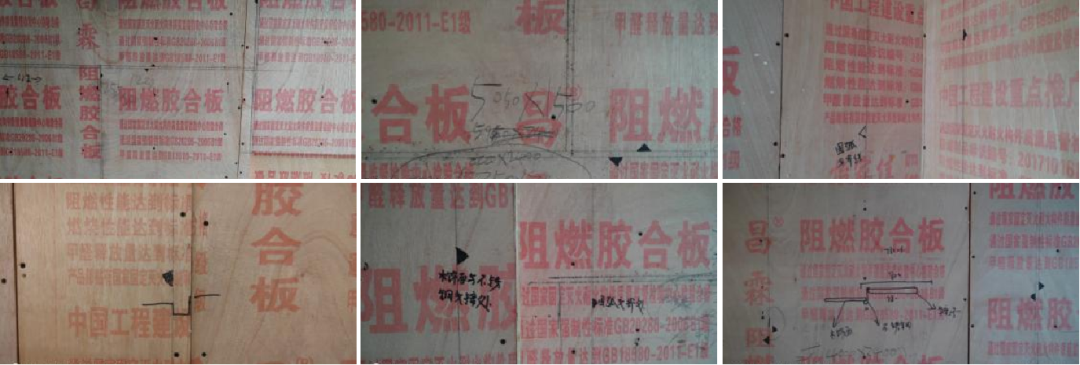

4, grass-roots bottoming practice

Reflections on grass-roots assembly construction: What conditions can be grass-roots assembly construction?

1, there are no other installation units in the room, is an empty scene, so that for some steel frame partition wall can be assembled construction, but this also needs to consider the installation of the code adjustment space.

2, non-top wall of the unit block requires a layer of ceiling seal installation support plate(200mm size can be).

3, a model between the manual consumption of this is not too much different from traditional practices, the only difference is that the unit block installation site is more clean and orderly.

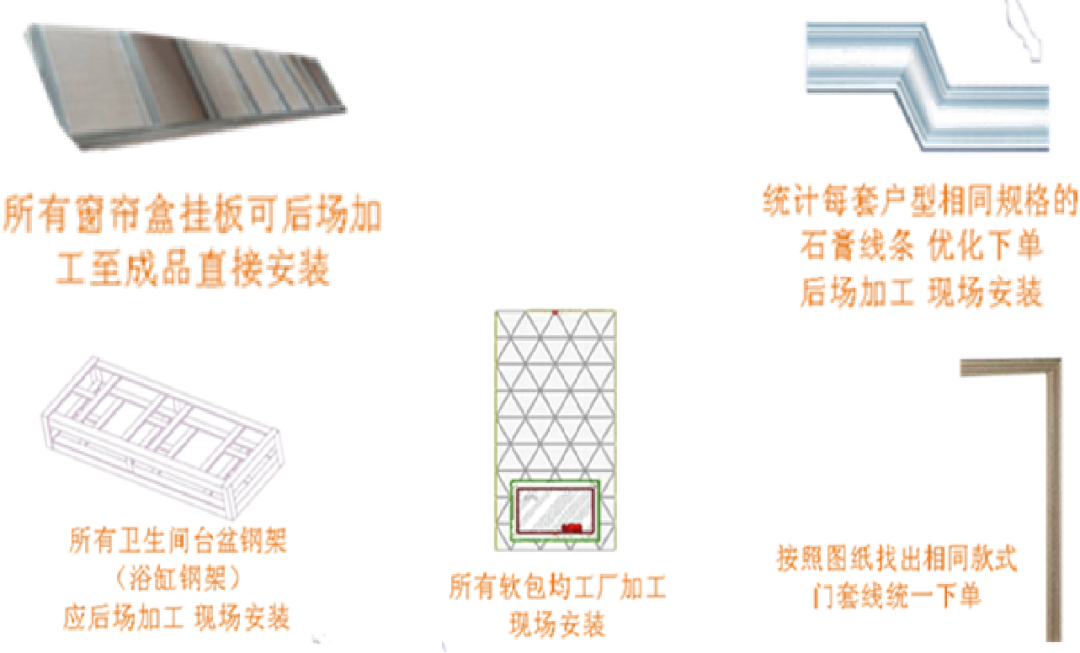

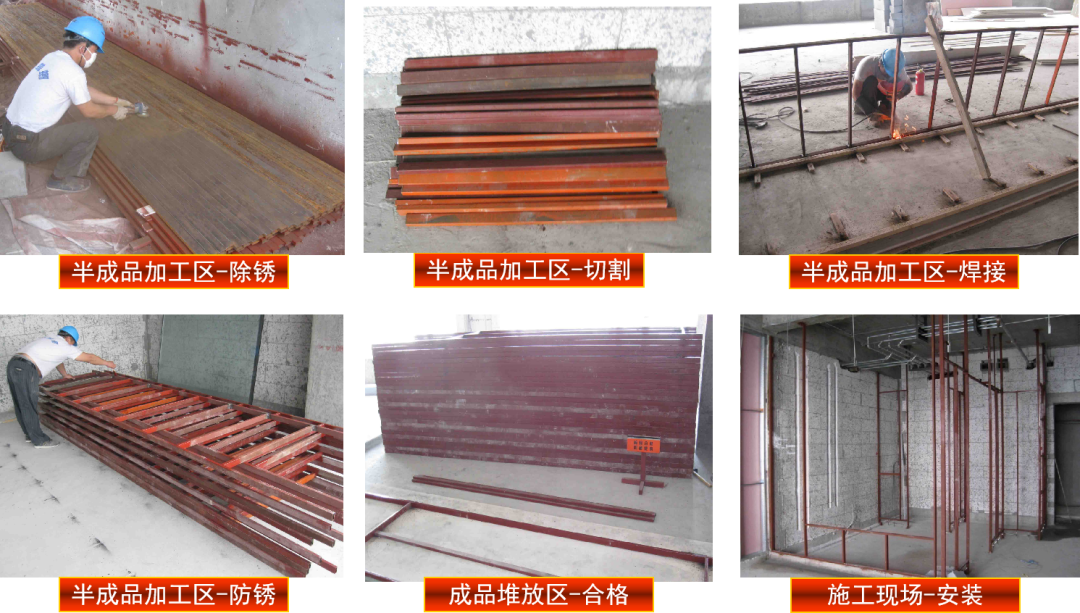

Conclusion: With the continuous development of product-based decoration, modularization is gradually popular, ordinary on-site production has been unable to meet the pace of decoration today, to speed up the pace of construction, improve construction quality and reduce construction costs, semi-finished products on-site processing is the trend.

1, semi-finished processing area main processing catalog

2, unit block processing site

3, bathroom steel frame processing

02

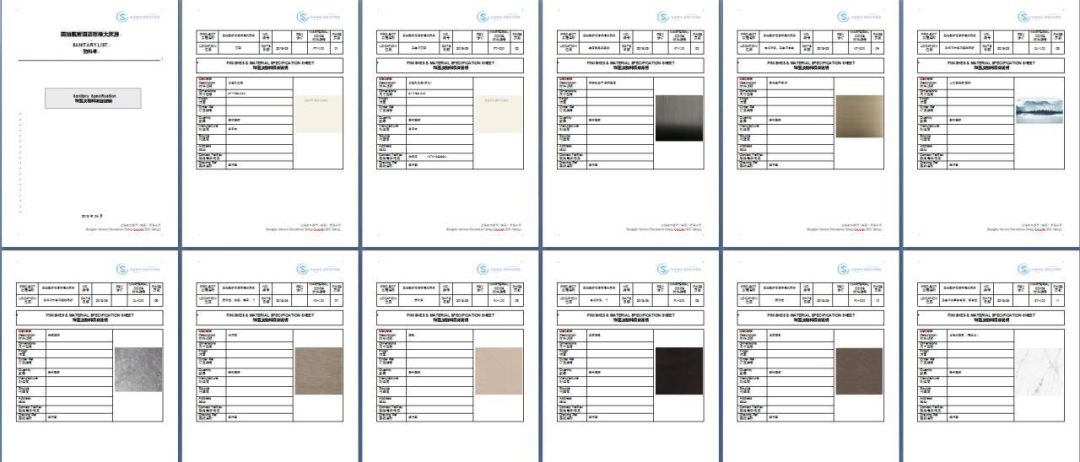

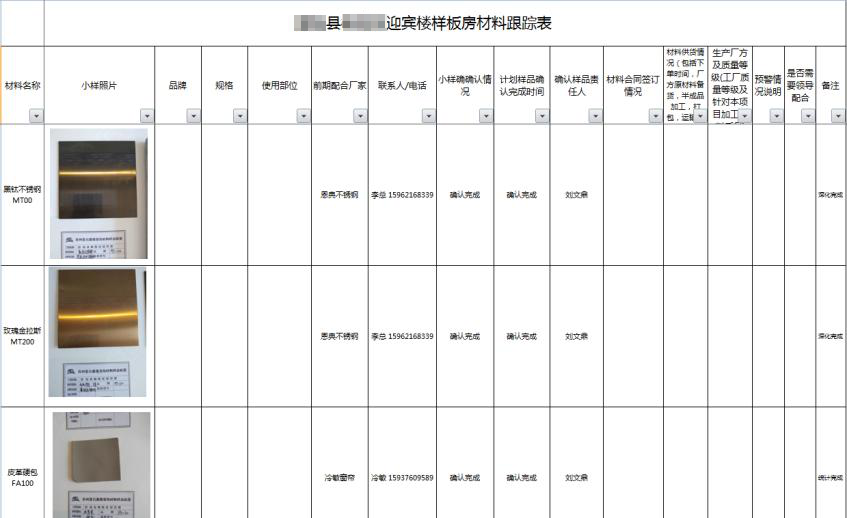

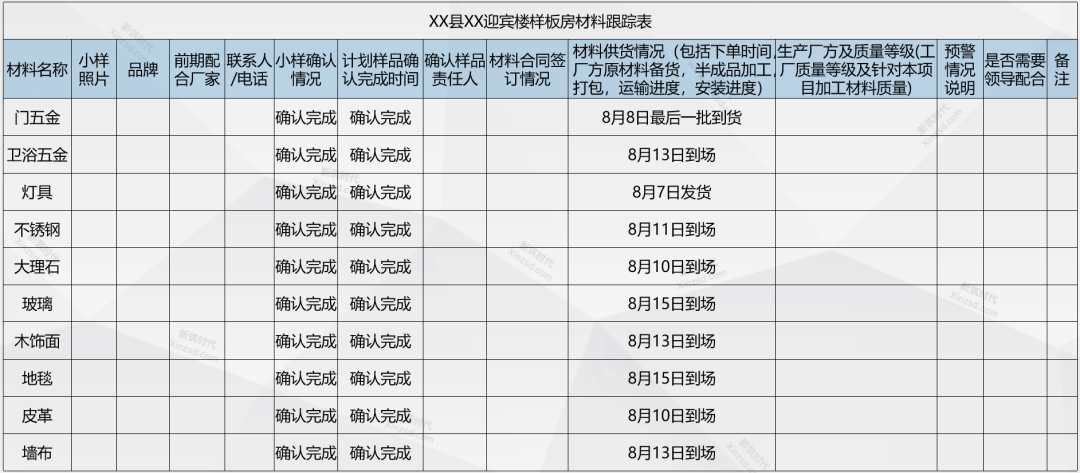

Material samples and project process material tracking

2.1

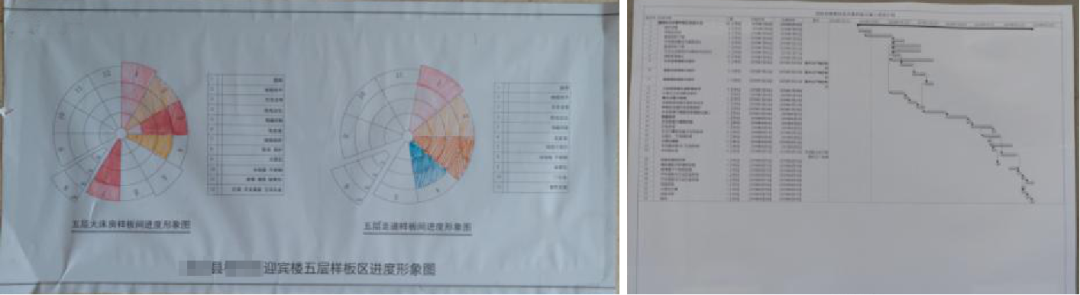

Model room material progress schedule analysis

Material material

Marble layout situation, maintenance personnel are checking the layout situation, there is a risk of cracking to repair one by one to strengthen.

Backfield processing track, stainless steel focus on those smallpox arc groove lines.

Material Tracking Table

2.2

Key process control analysis of heavy difficult material process

Each material is a conventional material, and the difficult materials are as follows:

1, bathroom scrub light mirror, need professional mirror manufacturers to polish because the model room is only a piece, so the transport is more difficult.

2, the room stainless steel frame 30mm, is made by 3 10mm stitching.

3, the production of inner arc leather hard bag, because the hard bag production of the sending and receiving and the process will make the inner arc can not be taut, and suppliers to communicate the use of the plastic process.

4, the door has a 20mm hard bag, and there is an arc, so far has not found a solution.

5, into the door tackle light-emitting door, following the practice on the node, can not achieve removable functions, need to adjust the program, the current plan to use strong magnet installation.

03

Key phases of the project focus on control

3.1

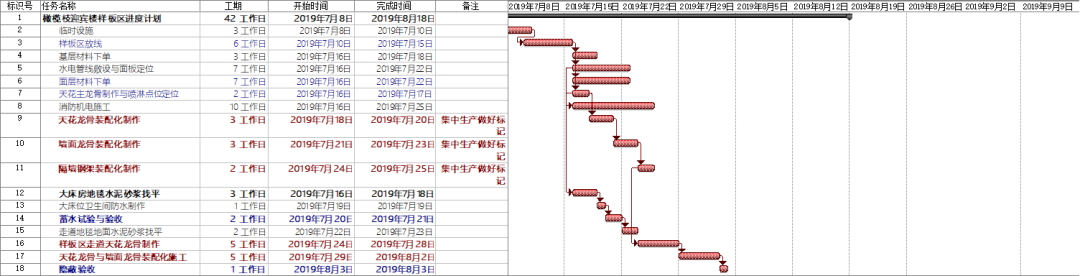

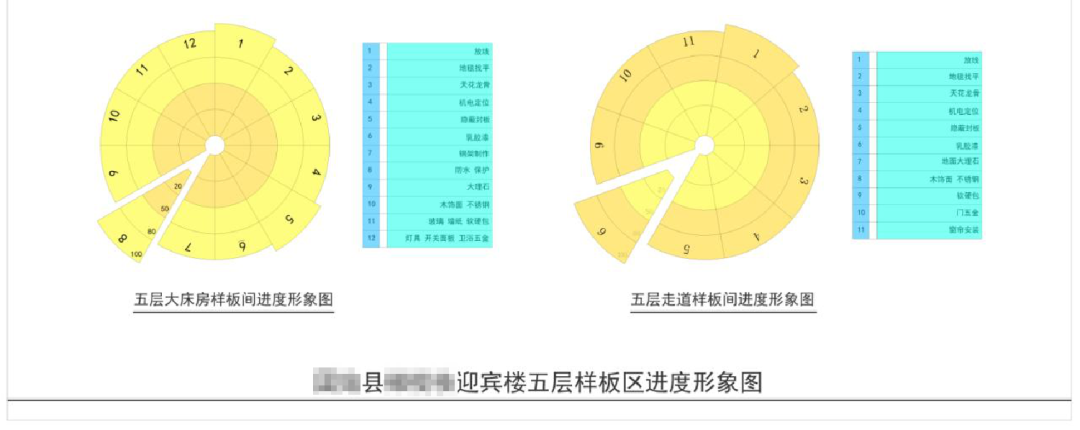

Construction schedule and progress image analysis

Construction schedule

Progress image

3.2

Line and grass-roots production of the bottom of the key explanation

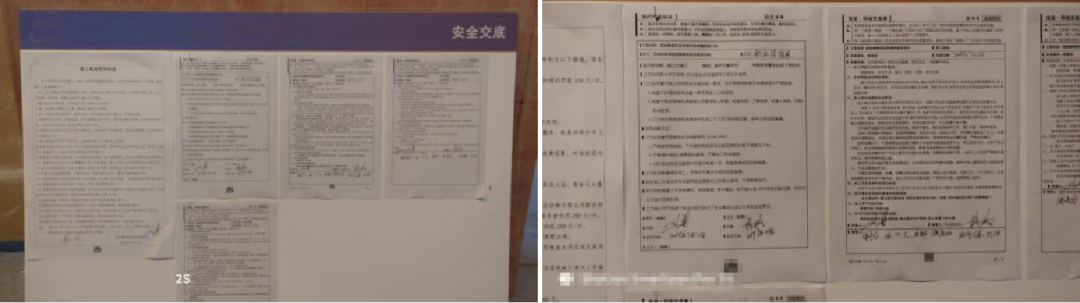

Safety cross-bottom shot on the wall, each type of work safety operation cross-bottom on the wall.

Progress image map and schedule on the wall, so that the owners each time to the scene can understand the scene through these two pictures, our department also for the image of the progress map to explain Party A, especially the big bid stage how effective control of key processes.

Work card and electric box check record.

Line map cross-bottomed wall, smallpox keel grass-roots typography cross-floor wall.

Put the line and the grass-roots production of the bottom.

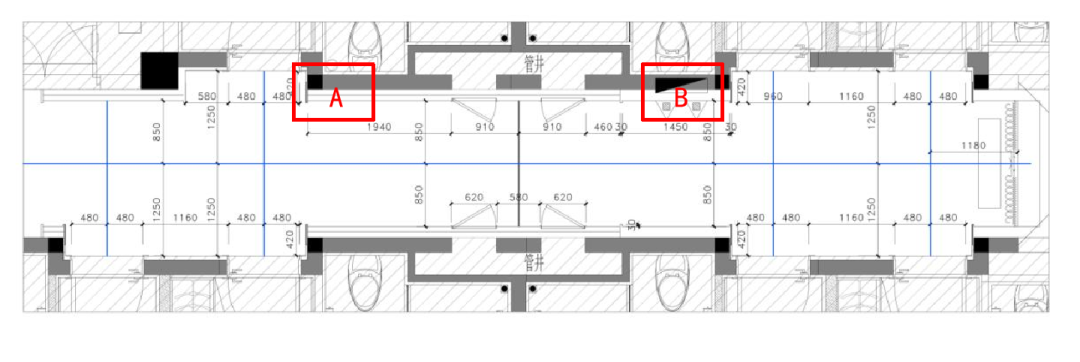

Design drawings firebox in A position, the site again B position, because of the owner’s construction principles, do not allow changes in the design, so the B position of the 1200 stainless steel dark door according to the actual situation on site enlarged to 1450.

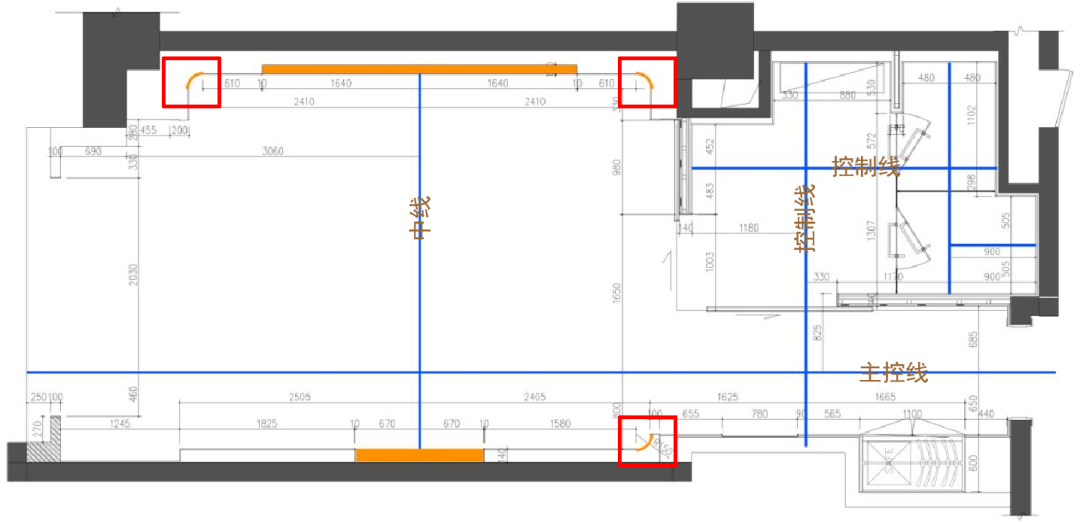

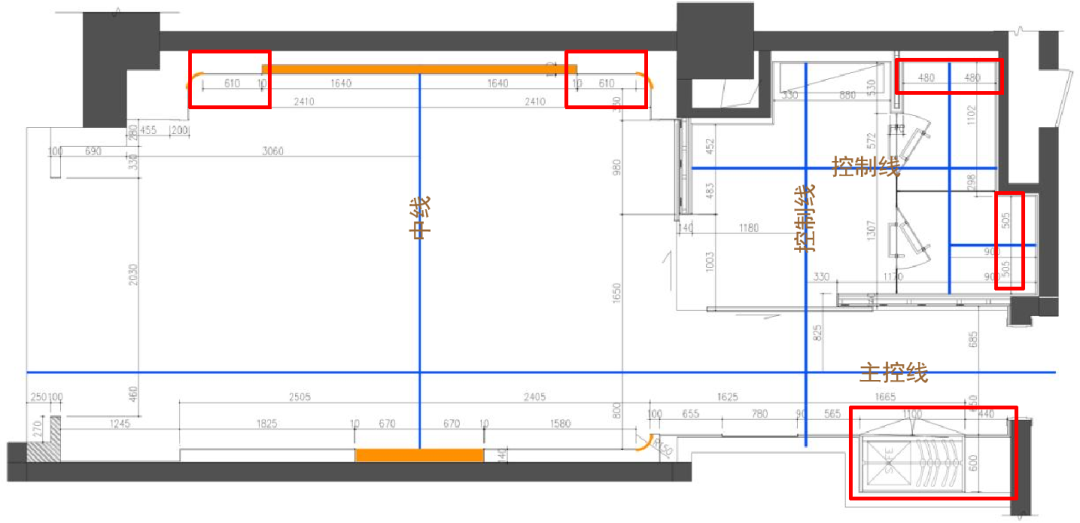

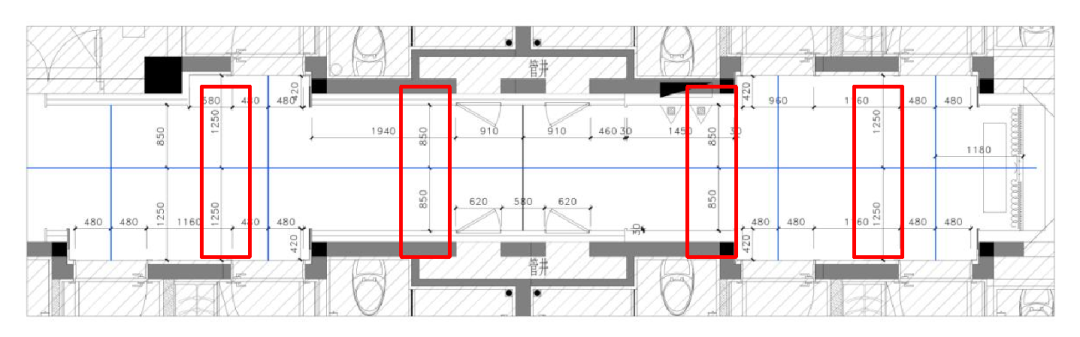

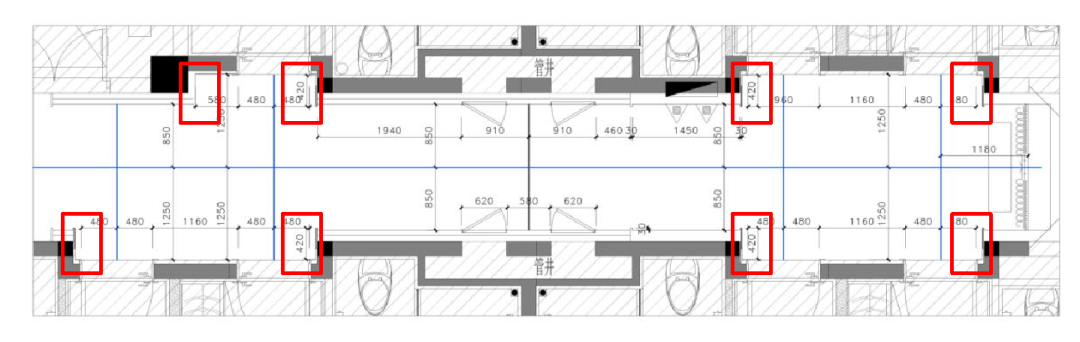

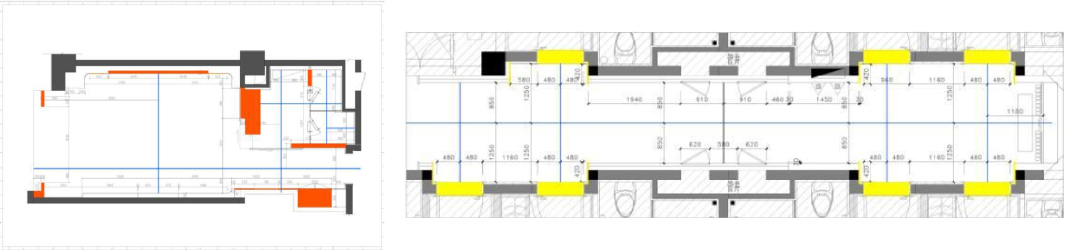

On the floor of the whole walkway, wall spacing measurements are completed to confirm the hollow line, in the line to pay great attention to the size in the red wireframe, these sets of dimensions are correspondingly unified to ensure that the walkway square and size symmetry.

According to the extension of the above dimensions, the dimensions in all the red boxes in the figure will be unified, ensuring that each door hole is the same size both to ensure unity and to place orders with the same size, which is the size area to be checked at the grass-roots level.

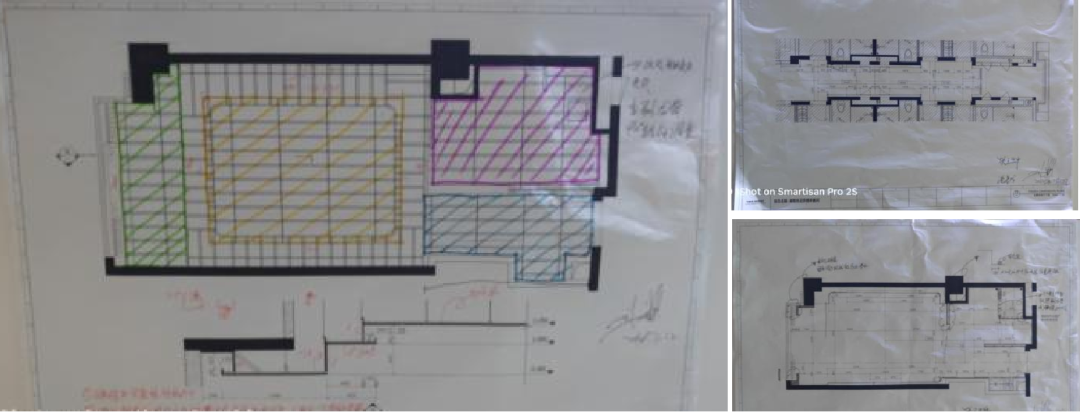

Will have unit production of regional marking, according to the actual situation of large-scale planning unit production.

Deepen the design drawing of the placement drawing and key position size control, will be finished face in the ground and wall, by extending the line directly and closed, so that you can see whether the actual dimension collision there is a conflict position, if not put line extension closed may lead to a closed position error leading to grass-roots changes.

Absorb the pain point before: sound insulation, my department’s treatment of sound insulation

1, the door cover base and the original wall gap using cement mortar to fill

2, all hidden pipe through the wall holes are filled before and after using cement mortar

3, TV and bed background plus a layer of soundproof cotton

The importance of secondary line release:

1, even if there are no line workers, the secondary line can still guide the installation of surface-mounted workers.

2, after the line of review size, can be accurately confirmed under the surface layer order.

3.3

Project key parts of the process summary control

1, spray forced positioning, corner reinforcement construction summary

Forced positioning and corner reinforcement, the use of open gypsum board positioning spray position is more accurate, the use of multi-layer plate for corner reinforcement can effectively prevent cracking quality disease.

Use balloons to protect against spray head contamination when painting latex paint.

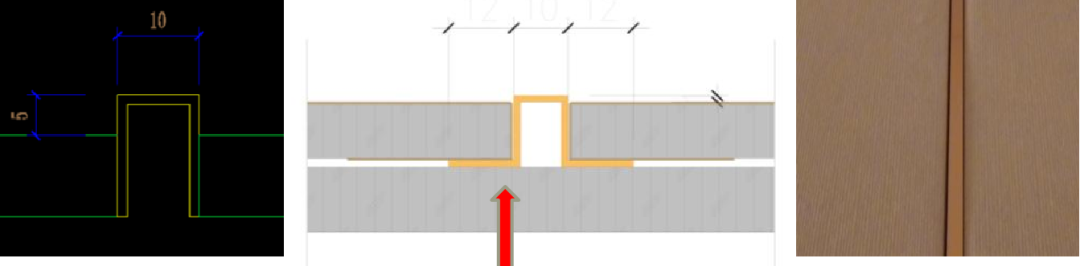

2, door cover grass-roots practice attention area

(1) Stainless steel groove reservation in the door number position;

The material of the position is stainless steel, ignoring the stainless steel groove of the position, resulting in the base of the position being added to the top of a layer of the flame retardant plate, time-consuming and laborious.

(2) The relationship between the door cover and the side stainless steel overlay;

We do the position of the grass-roots on the ignore the position of the door cover and side stainless steel stacking relationship, the master to do the grass-roots easy to follow the civil grass-roots line production grass-roots, after doing found that some of the wrong, and readjustment.

3, the ground stone corner adjustment problem summary

(1) The problem of the position division method of the corner of the ground stone;

Because of the corner position the most overall look at the face large and small different to do 45-degree angle feel not the straight-spelling effect is good, but at that time when placing an order did not take into account this problem.

(2) Ground stone determination, variable problems;

Gate position quantitative and variable stone size set the opposite, stone under the order only want to “door cover size fixed, the size of this stone fixed, the next size to do long, but ignored this stone against the wall, should be next to the stone to do fixed size, this to adjust the size, eventually leading to this stone split to the left offset 5mm.”

(3) Wall stone and stainless steel outlet problem;

Because the bathroom countertop outstretched wall end stainless steel can not highlight the wall finish surface otherwise the bathroom countertop has protrusions, but such a high risk of closing, slightly different stainless steel can be very clearly seen, and finally, the stone highlights stainless steel 2mm problems.

4, stainless steel arc and hard package inside the arc case summary

(1) Stainless steel arc and hard package inner arc;

This location was supposed to be well thought out, but there was a problem with the installation. First, the inner arc of stainless steel is not folded in the same batch, stainless steel arc between 3mm error, and second, the inner arc of the grass plate deformation, side bending phenomenon, resulting in the installation of hard package split size.

(2) “Several” glyph stainless steel installation problems;

Between the stainless steel side strip and the hard bag we intended to do “u” shape (Figure 1), but after considering the basic deformation, appearance effect, and other issues, decided to use “a few” glyphs (Figure 2), but after installation stainless steel edges some up, Finally stainless steel and a hard bag of the closing and expectations of some difference, the next time in this stainless steel line installation must be inward.

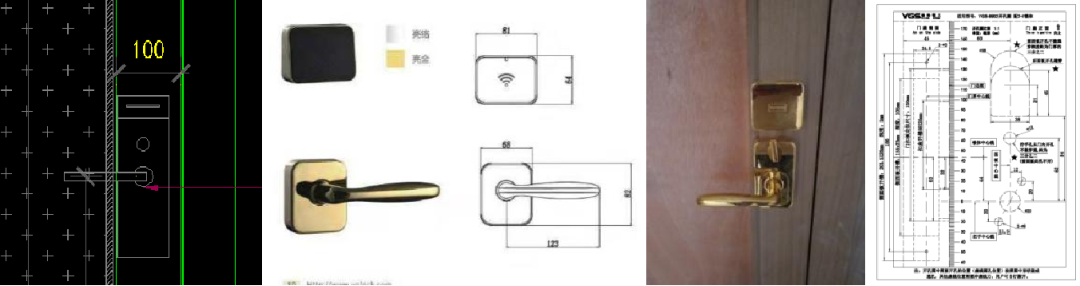

5, wood decoration facade side modeling and door lock adjustment case summary

(1) Wood decoration Face side styling and door lock problem;

At that time, check the wood finish drawings only check whether the border size is greater than the width of the door lock, ignore the size of the lock body handle from the door side, resulting in the door lock deviating from the door frame shape, if you can check at that time, you can solve this problem in advance, to avoid this problem.

(2) Wood decoration Face-side pages The bottom of the cross-section is not clear;

Wood finish door installation cross-section is not clear enough, there is no door-to-door installation method for “box three doors two”, resulting in a piece of the joint page back and three screws are not original.

The project manager is the key role in determining the success or failure of the project, and in the project construction management, he should have the following abilities in addition to the “concrete functions” of the general manager such as planning, organization, decision-making, control, coordination, etc

1, internal: coordinate tasks and allocate resources, control and guide the daily work of the project, coordinate the progress, quality, and cost of the project objectives, the ability to effectively manage and control possible risks;

2. External: contact with project funders and individuals, obtain external resources, participate in negotiations in the operation of the project, and do a good job of coordinating with other projects. More emphasis on technical experience, decision-making, etc…

That is, the project manager is required to be both a “project organization commander” and “planning and implementation supervisor, a hub for project coordination, a control center” and, finally, a qualified contract performance officer.