4 Big Job Grabs, Are You Ready for It? Project preemption experience sharing

Senior project managers, deeper design, and construction staff who have long looked forward to the project know that almost 60% of projects are preemptive for a variety of reasons.

Some due to the project design program rectification, or because of the project process personnel transfer adjustment, or because of the political task requiring the project to rob workers, the project disorderly management caused by the late rush, the end of the year rush is also a frequent occurrence.

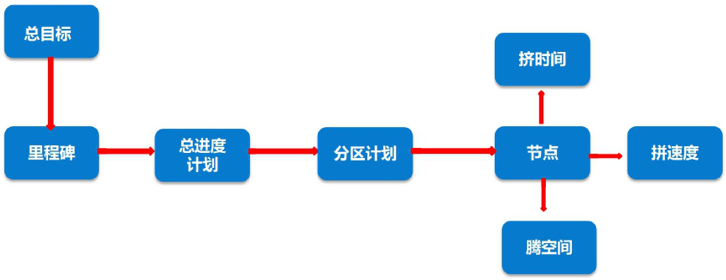

How to “squeeze time, free space, spell speed” of the project according to the central guiding ideology of the project construction organization design in the process of clear implementation of the project?

About the rush to work time to face several engineering difficulties, how to achieve trilateral promotion, grasp the progress control points, annihilate the construction difficulties.

01

The overall idea of job-snatching

1.1

Rushing ideas

Due to the short duration, all plans must be completed on time to meet the schedule requirements.

1.2

The determination of the overall schedule

Total schedule

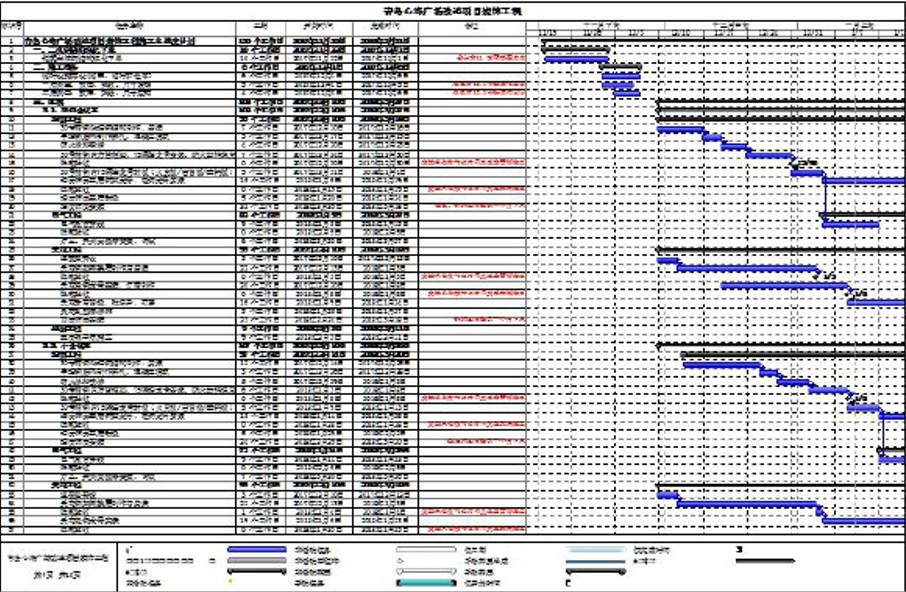

According to the node plan to refine the specific process construction plan for each period, to develop a rigorous and reasonable overall work schedule.

The total schedule is adjusted, and the process is executed

The principle of pre-grabbing does not rob the late, rob the grass-roots do not rob the face layer.

1.3

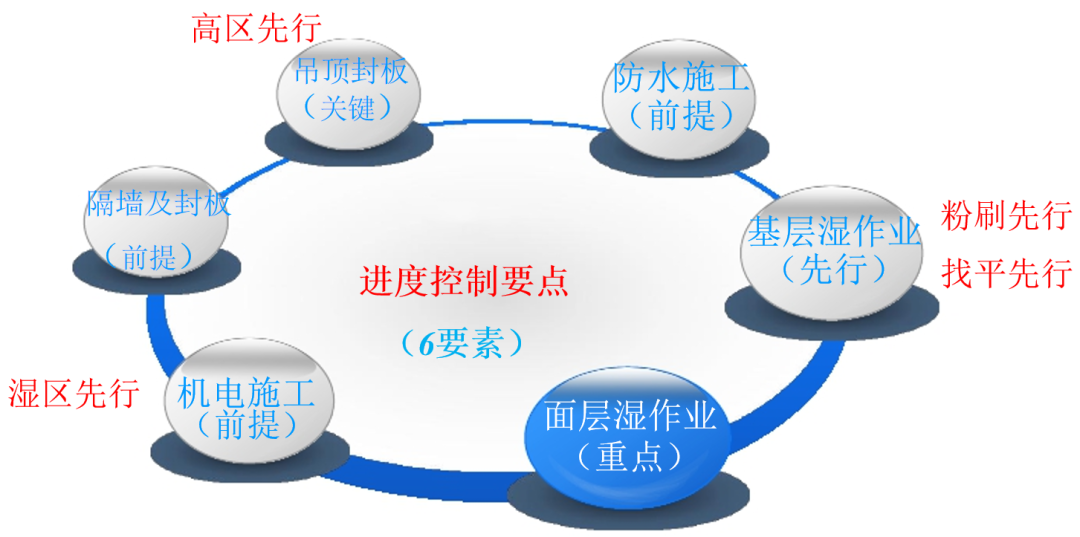

Engineering difficulties and progress control points

The overall duration of six months, three months of fine decoration, not only across the Spring Festival, winter construction, but also a typical side design, side deepening, side construction projects.

02

Difficult measures to solve

2.1

Three-sided project how to advance?

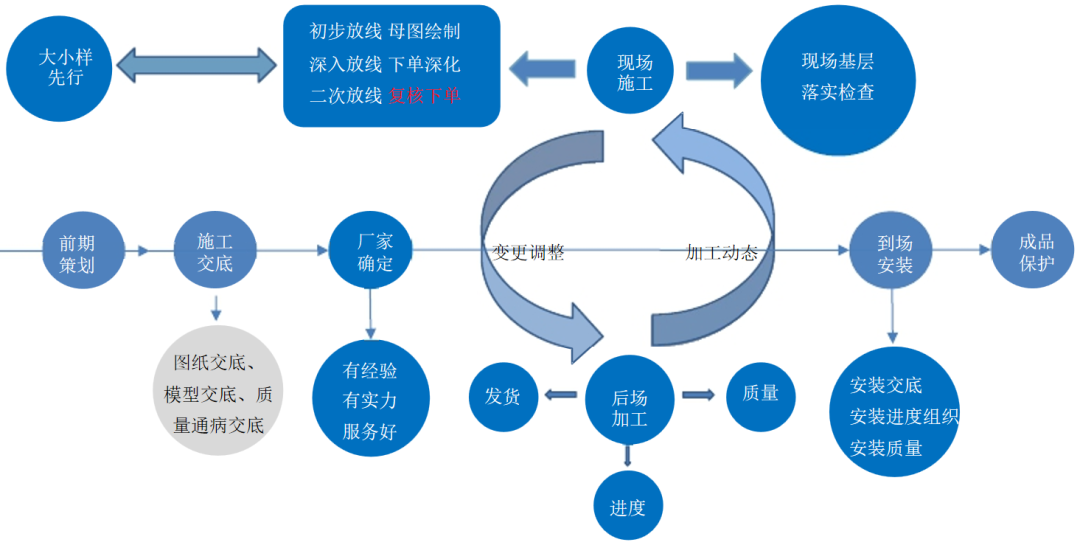

Three-sided: side design, side deepening, side construction project.

- Measure 1: Early intervention, human-sea tactics

1, early intervention, with the design institute to draw construction drawings;

2, the peak of the number of deepening design up to 23 people;

3, group management to improve the efficiency of deepening.

Deepen the designers to work overtime at night

- Measure 2: Make a plan, responsibility to the person

Group deepening schedule and joint manufacturers to place an order schedule (responsibility to person).

- Measure 3:BIM assist, quick order

1, the establishment of a professional BIM team, the effect map is determined, then began to model the difficulties;

2, after the model is completed, can find the closing error in time, can be faster and more intuitive to the designer to provide a solution, confirmation program;

3, the use of modeling techniques to steel frame conversion layer and metal ceiling surface layer modeling, effectively reduces errors in construction, rework.

VIP lounge white copper stainless steel top surface model, soft film ceiling deepening map, soft film ceiling processing map

2.2

How do I rush work in an ultra-short schedule?

After the project department analyzes the characteristics of the construction area and the project milestone node, it is confirmed that only the completion of the main channel can complete the construction task as required.

Through the meeting area key line combing, determine the key nodes, according to the progress of the company trust all-round support, to ensure the key nodes.

- First, determine the main channel

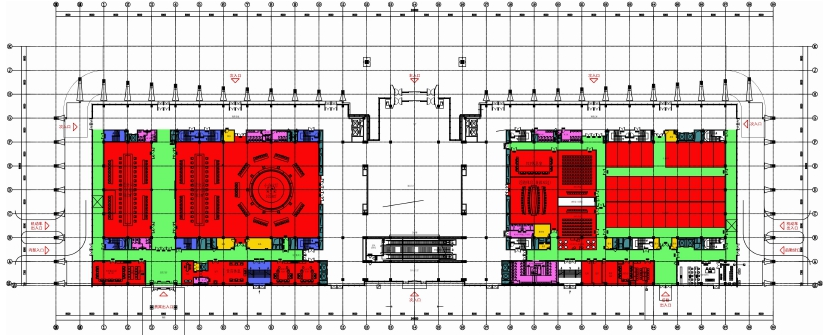

The red area is the main waterway, and the full-time responsible person shall be arranged according to the region

- Second, determine the key nodes

The read operation is the top five key nodes in the critical line

- Third, determine the measures to ensure key nodes

1, to achieve more soldiers will be wide

All work surface areas must be adequately staffed.

2, to achieve resource integration

Give priority to project experience and preemption capability suppliers to ensure the supply of materials.

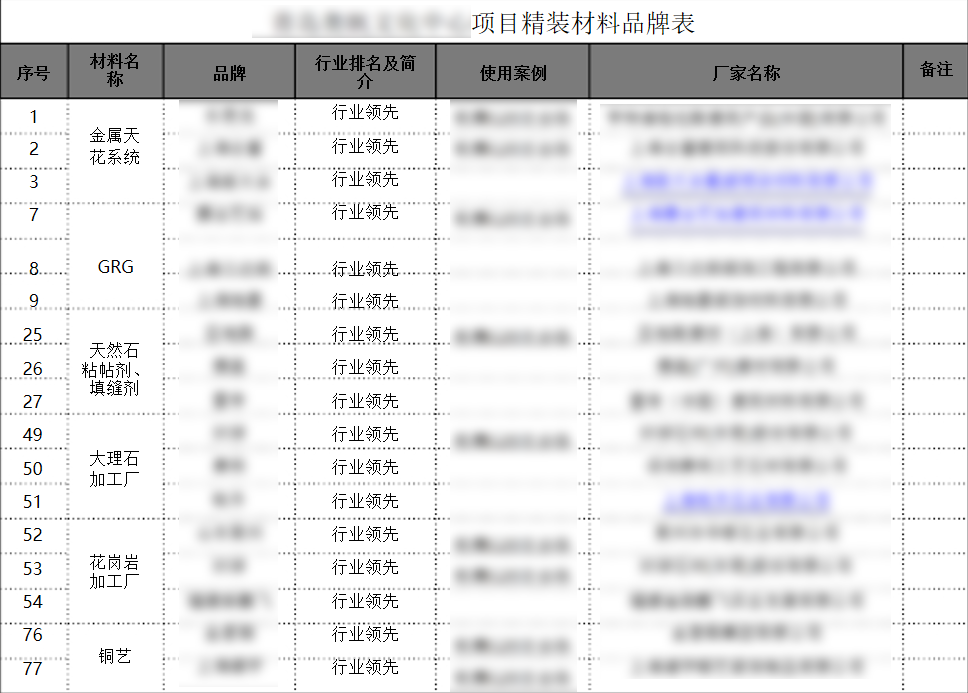

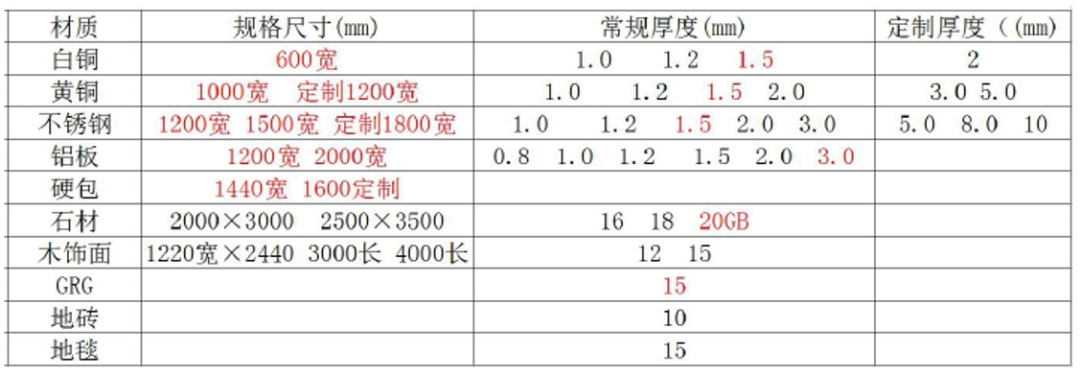

Report materials according to the owner and environmental requirements Brand Table

3, to achieve the sample first

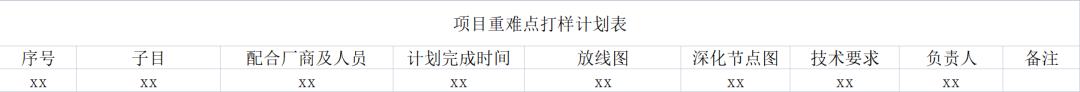

Make a big plan to determine the tracker, responsible person, technical requirements, node completion time, etc.

If multiple proofings occur and the design intent is not met, the matter is personally watched by the project manager.

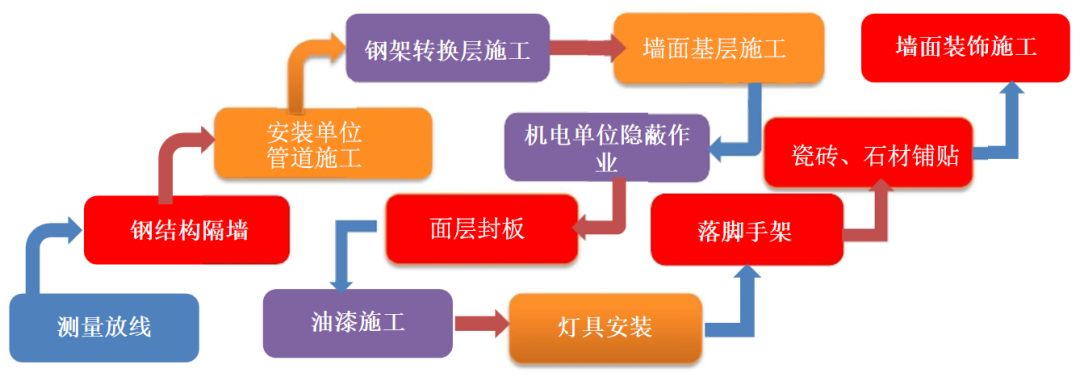

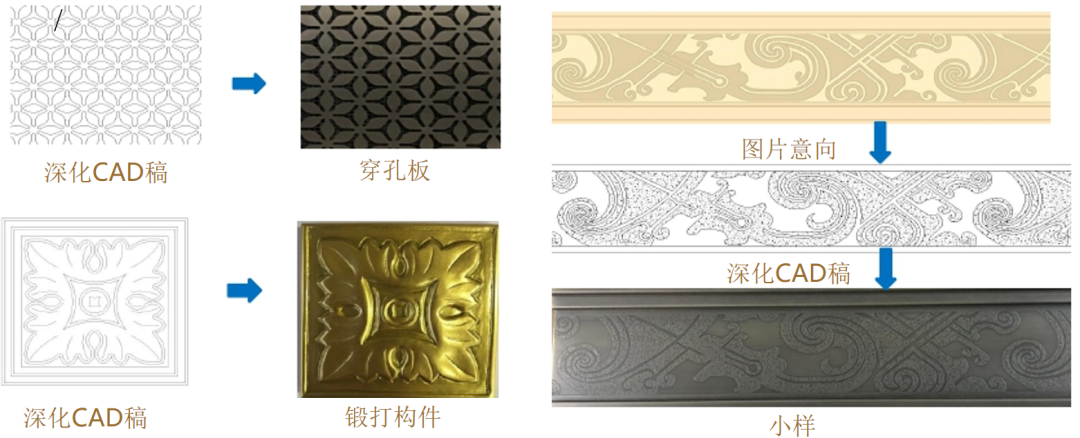

Proofing process

In the process of model confirmation, deepening typography, modeling, backfield preparation, and site grass-roots construction are carried out simultaneously;

2.3

How does the material cycle break through the routine?

Due to the project duration being very short, resulting in materials after the order material processing, installation time according to the regular winter construction, across the Spring Festival conditions simply can not be completed.

According to the design effect map, the amount of stone, metal, and hard packaging in the project is not always large, whether to control the supply, installation progress, and installation quality, will become the key to the project can be delivered on time and success.

The Project Department identifies stone, metal, and hard packs as the main channel for the project materials.

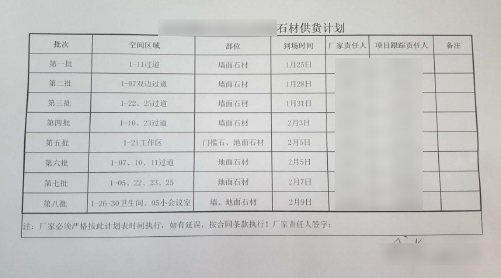

- Focus one: stone supply, installation measures

The person in charge of the manufacturer signs a military writ (note penalty clause) as an attachment to the contract, which is supplied in strict accordance with the plan, otherwise, the contract will be held accountable.

The company’s engineering management department arranged a full-time material staff backfield tracking stone supply and quality, to ensure that the Spring Festival logistics stop before the arrival time.

Pick a large plate

Cutting plate selection and backfield typography

To ensure the duration, the wall, the ground every four teams at the same time flowing water construction.

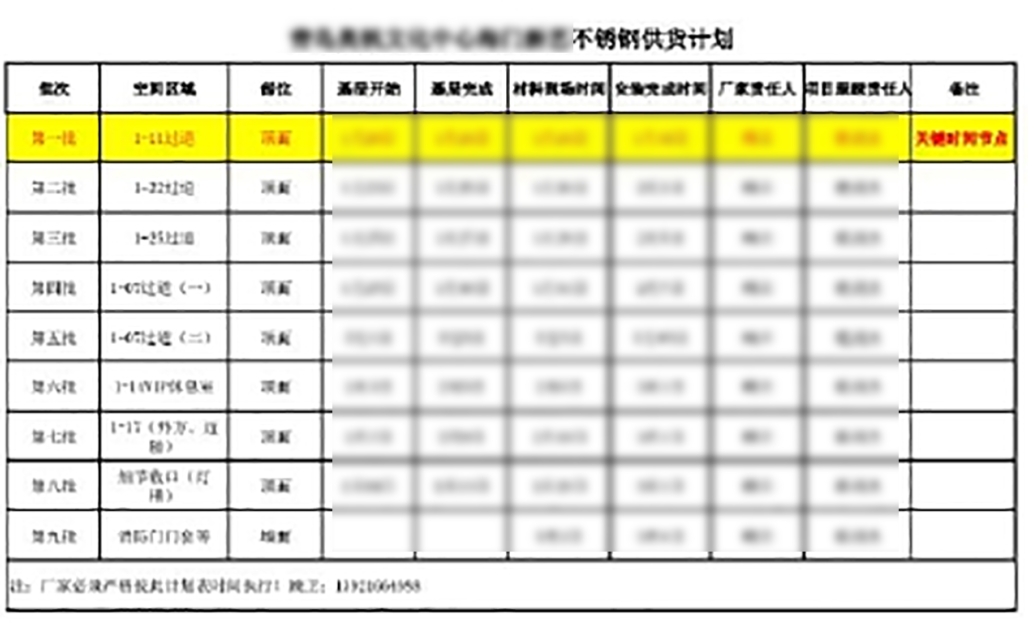

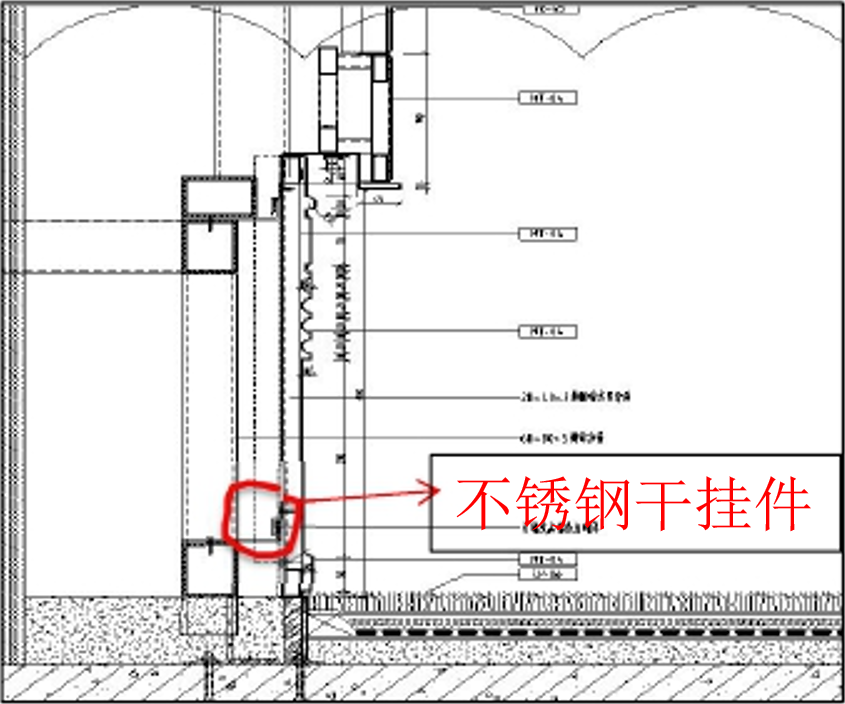

- Focus two: metal (stainless steel) supply, installation measures

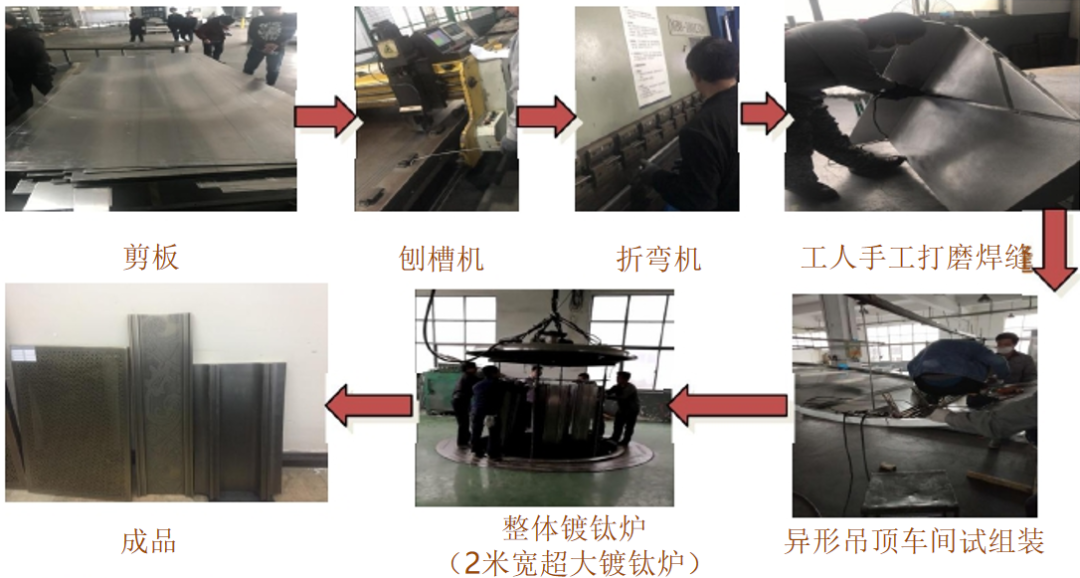

Stainless steel project as the largest project volume, the construction of the most complex single project, to ensure the duration node and installation accuracy requirements, which the shape of the early molding, while the Spring Festival after the field overtime unified arrangements, by the head office engineering management department for backfield tracking and coordination.

Stainless steel supplier supply military writ

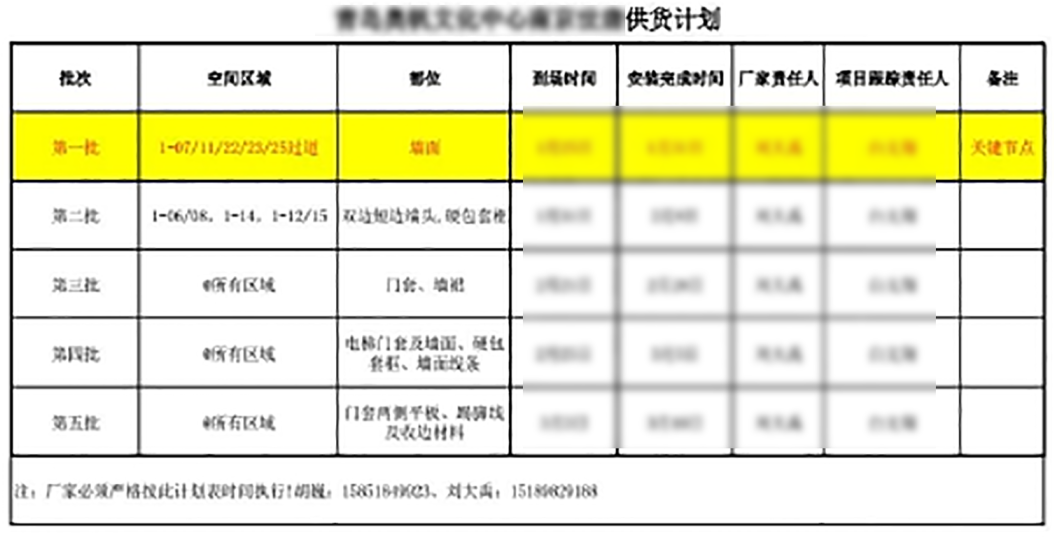

- Focus three: hard package supply, installation measures

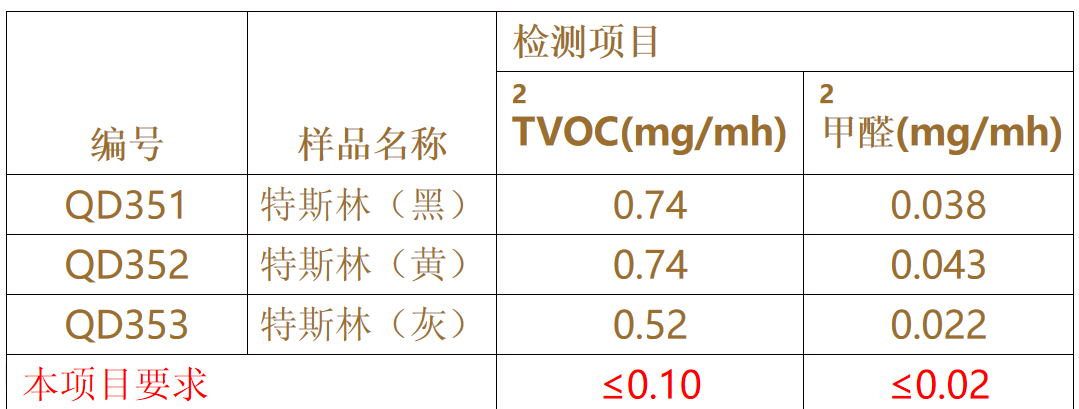

Project Hardpack engineering volume is high – most of the material is PVC material, TVOC and formaldehyde content is difficult to meet the standard.

Project Environmental requirements are high – national standard formaldehyde standard 0.08mg/m2h,on-site requirements 0.02mg/m2h.

State inspection sampling of the wall cloth testing is not qualified, resulting in the hard package cloth work being suspended.

If the re-inspection results are still not qualified, may face re-selection of cloth, production, and processing, the duration is difficult to guarantee.

In the face of this issue, the Project Decided:

1, please lead the company stationed manufacturers, coordinate manufacturers to increase the intensity of measures;

2, invite the inspection group experts to the backfield to guide the improvement measures;

3, the company material supply line to find a ready replacement manufacturer, under the conditions of coordination of other programs.

After all the efforts of all parties, the final fabric sampling all qualified.

Comparison of the G20 project in Hangzhou with the installation progress of this project

2.4

How is three parallel construction managed?

- Civil construction is parallel to decoration

“Speculative” method of work

In the face of construction pressure, seize any opportunity to advance the progress of construction, that is, “speculation”;

Taking all possible steps to facilitate progress is “trickle-by-grab”.

1, one of the “speculations”

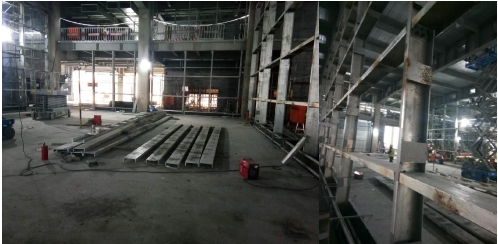

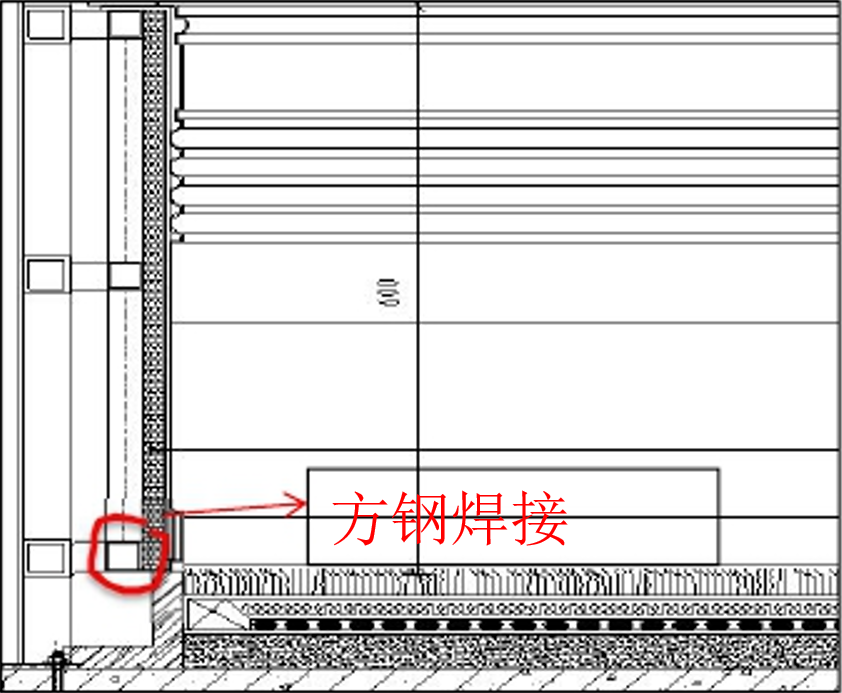

Construction of steel structural partition walls

The original partition wall design scheme is a masonry wall.

Due to the tight schedule, large engineering volume, cold weather, and insufficient supply of external masonry materials, the masonry scheme does not meet the actual demand. All parties worked together, led by the Architectural Design Institute to eventually adopt the steel structure partition wall scheme.

Once the scenario is determined, the project department takes the initiative to work closely together, from the material entry to the installation completed in only 15 days.

2, “speculation” II

Entering the site begins with a large area of tiles

Entering at the end of December, the temperature is not very low, the original construction order is the top of the wall.

And because of civil ash and mechanical and electrical progress, large-scale construction can not be. The project department decided decisively, the adjustment plan to lay the ground first, seize the rare opportunity of wet work for the back to win the opportunity.

3, “trickle-by-trick”

One layer of mezzanine and all fire stairs Original design paste paint, due to the average temperature in Qingdao in January -2 to 5 degrees Celsius, taking into account the civil dust cycle and winter construction environmental factors, I recommend that the owners change the use of dragon gypsum board instead of plaster, It is helpful to mechanical and electrical pipe management, reasonable cost, high flatness, greatly shorten the duration.

- Electromechanical and decorative parallel

“One center, two basic points” method of work

One “center” is the decorative progress and effect center, and the two “basic points” are functional and secure.

For the project is the decoration unit in the functional practical and safe basis on the overall effect of absolute responsibility, other mechanical and electrical units unconditionally meet the decoration needs.

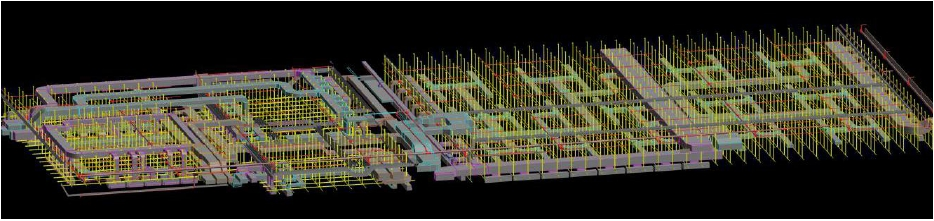

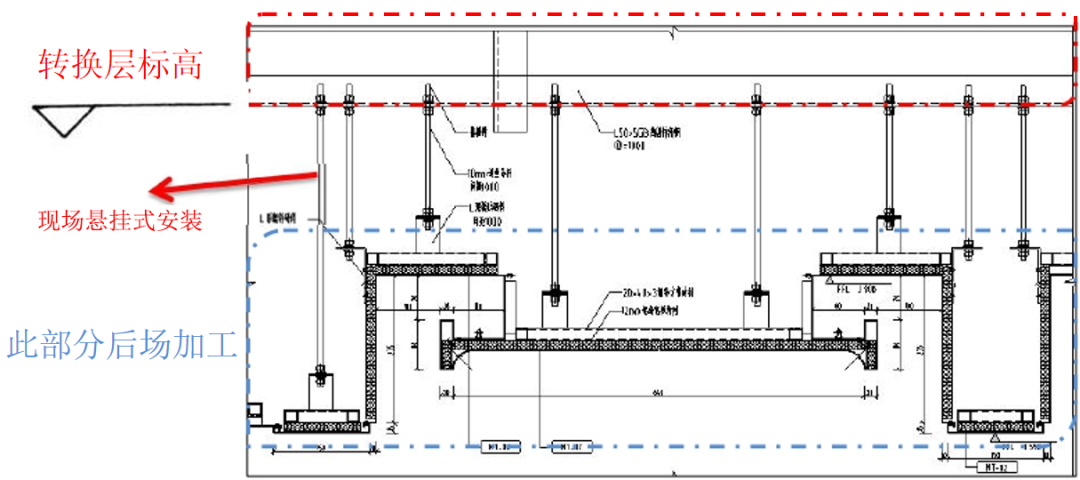

1, lead BIM collision detection, guide the construction

Collision detection of ceiling conversion layer and ducts

Due to the tight schedule, when the decoration unit scaffolding is completed, there will be various mechanical and electrical units and decorative units competing for work surface matters.

Decorative units lead the collision detection of electromechanical BIM models and ceiling conversion layer models in advance and construct according to the model.

All parties who are wrong who change, to ensure that the speed and do not rip.

2, decorative units forced positioning

Forced positioning of electromechanical points;

Ensure that all parties point unified opening to the decorative unit, to ensure the decorative effect.

3, decorative unit surface installation priority

Everything takes the installation duration of decorative surfaces as a priority.

The electromechanical unit shall not affect the surface installation node, shall be coordinated by the head package, and the parties shall sign and confirm the relevant regional commitments.

- The front and backfields are parallel

“First-line through, finished construction” work method

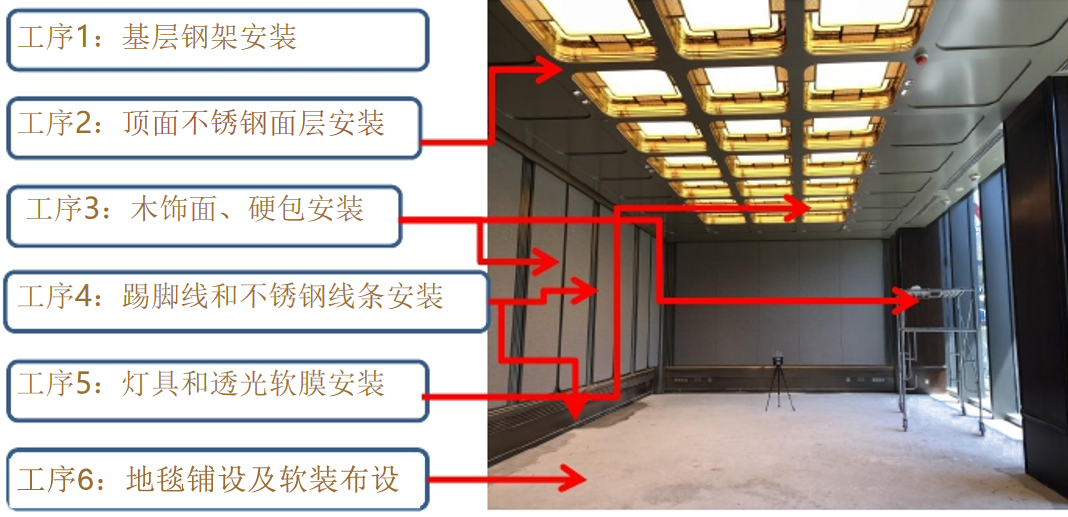

Effect figure

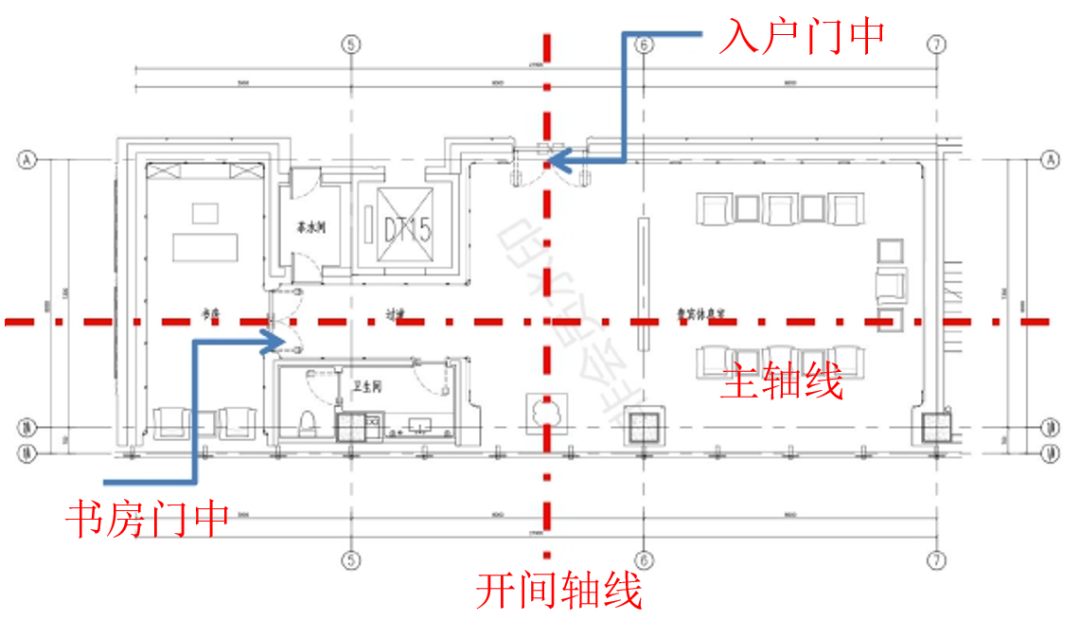

1, determine the axis

Three-axis correspondence – spindle through

According to the design effect, the door axis determines the accuracy of the interior size. So the use of three-dimensional line, three-axis correspondence, the origin start, spindle through, base point extension.

Effect figure

Floor plan

2, selected specifications

To ensure a perfect design, maximize the size of the material according to the surface material specifications.

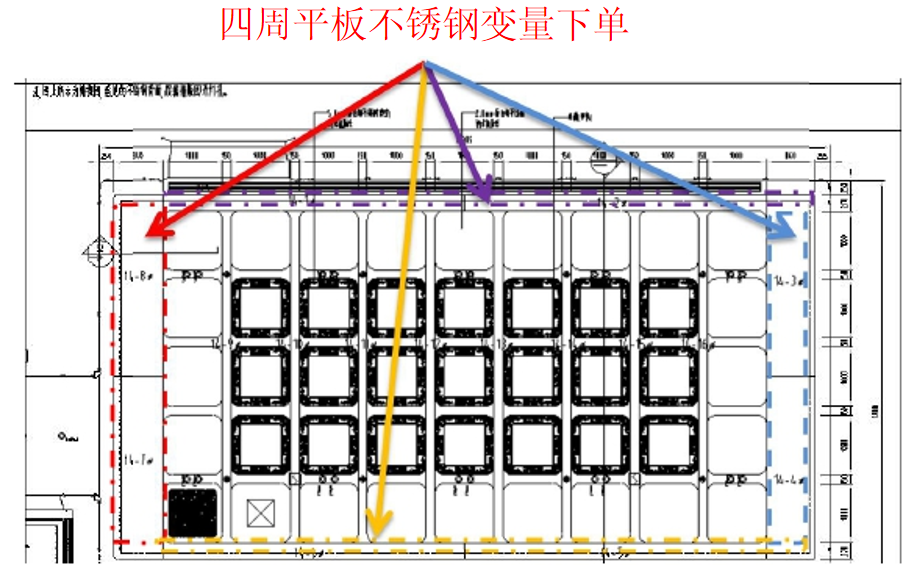

This area the most complex part is the top surface imitation white copper shape stainless steel, select the site priority layout, short-term whole, long items by shape block.

Stainless steel chunks

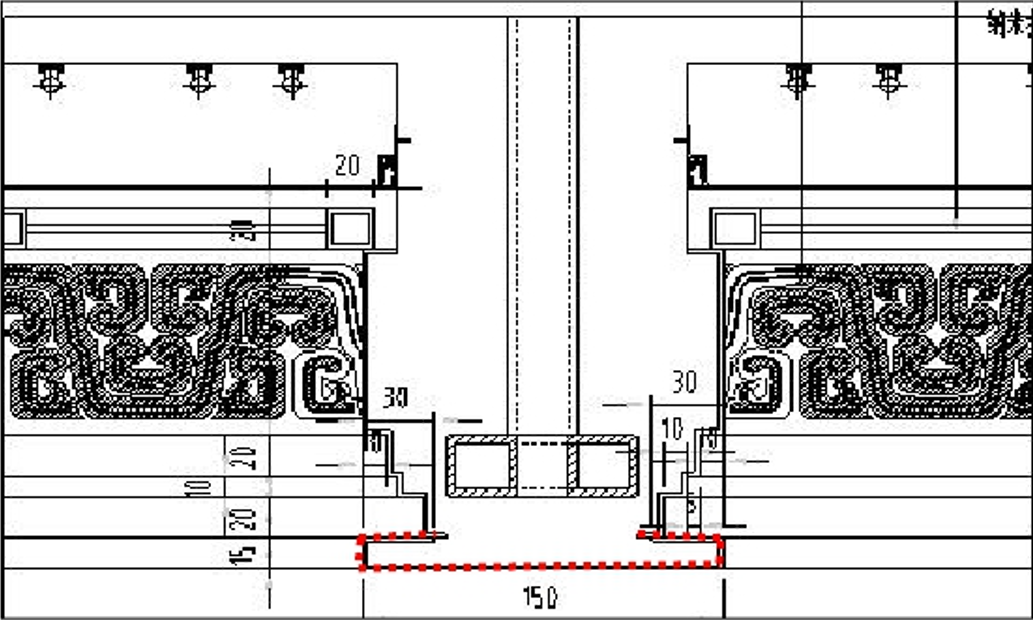

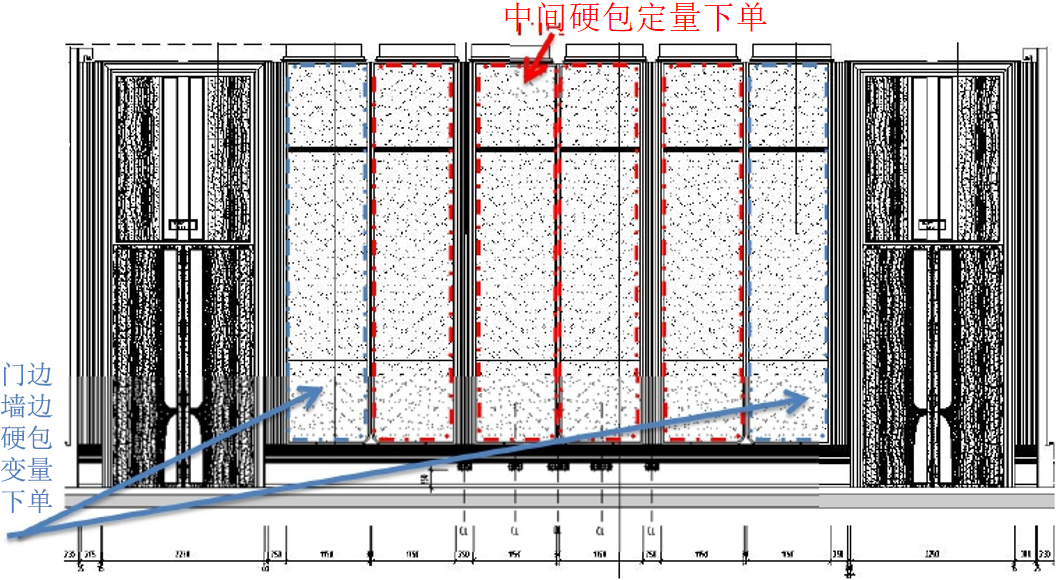

The hard-packed seams of the wall correspond to the top surface, and when coming to the door or corner, adjust the plate size appropriately and do not allow for more than or less than 1/3 of the plate size. To avoid quality problems, when placing an order, ensure that the stainless steel pressure hard pack per side is not less than 10mm.

Hard-packed chunks

3, optimize the node

Kickline optimization before

After the kickline is optimized

After node optimization, the transport deformation is eliminated and the installation convenience is accelerated.

The top-facing molding node is optimized for two parts, with the molding and connecting plates

After the node optimization, the seams are in the molding groove, which eliminates the seams and is more holistic.

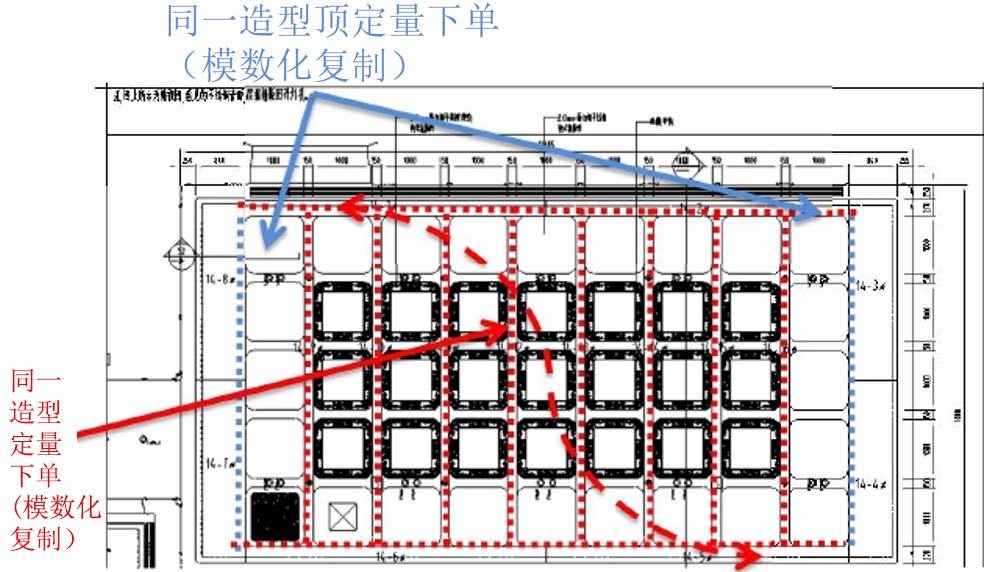

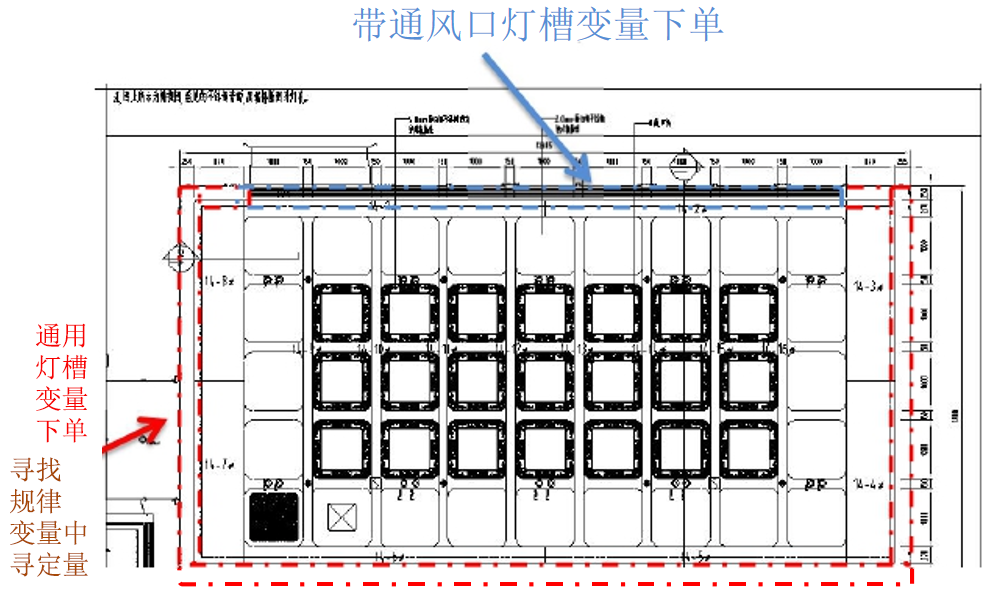

4, set the variable to order

The quantitative first, complex process first

Top faux white copper stainless steel fixed variable under the order

Find quantitative, quantitative maximization in variables

Find quantitative, variable minimized, in variables

Closing relationship:

Metal door cover pressure hard bag, first hard package order, and ensure that the door cover pressure hard bag not less than 15mm.

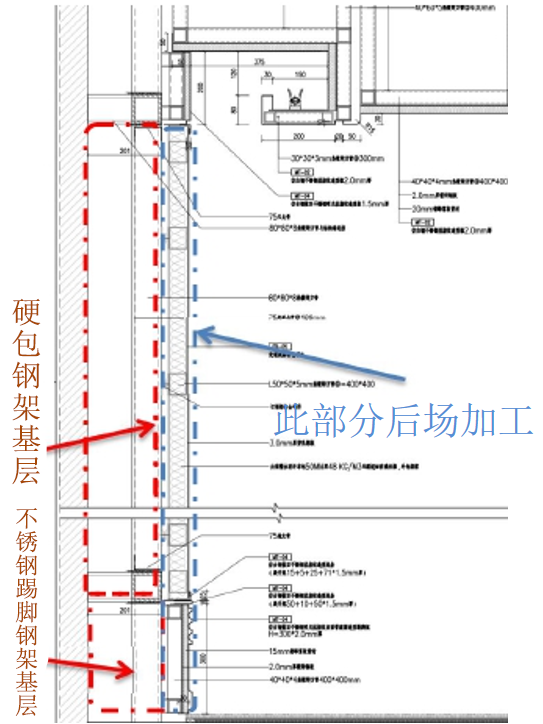

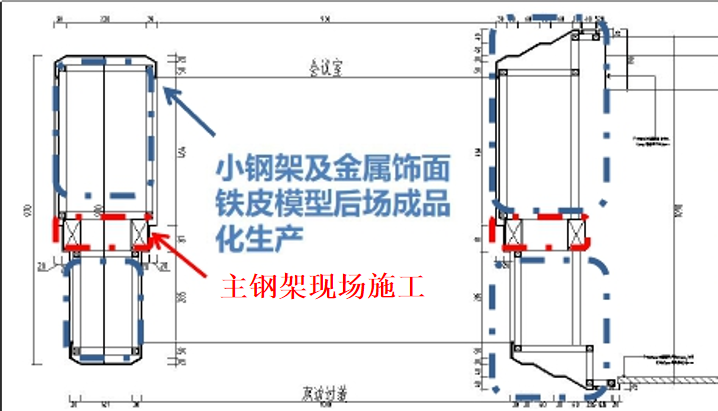

5, the grass-roots modular construction

The Wall surface layer pushes back the grass-roots line, horizontal, vertical steel frame according to the specification spacing molded construction. At the door, ensure that the steel frame is not less than 300MM from the door cover stop.

Top surface layer anti-push conversion layer elevation, horizontal, vertical steel frame according to the specification spacing molded construction.

6, backfield product processing

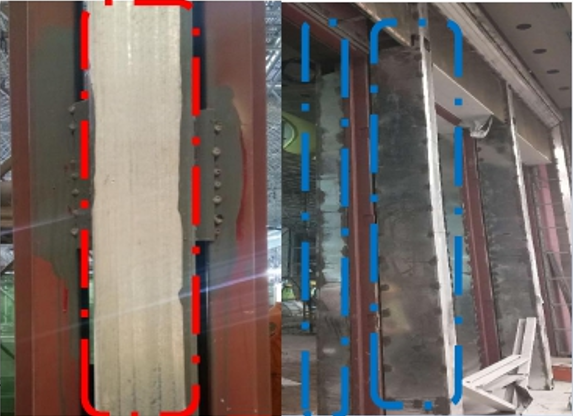

Stainless steel rear field product processing

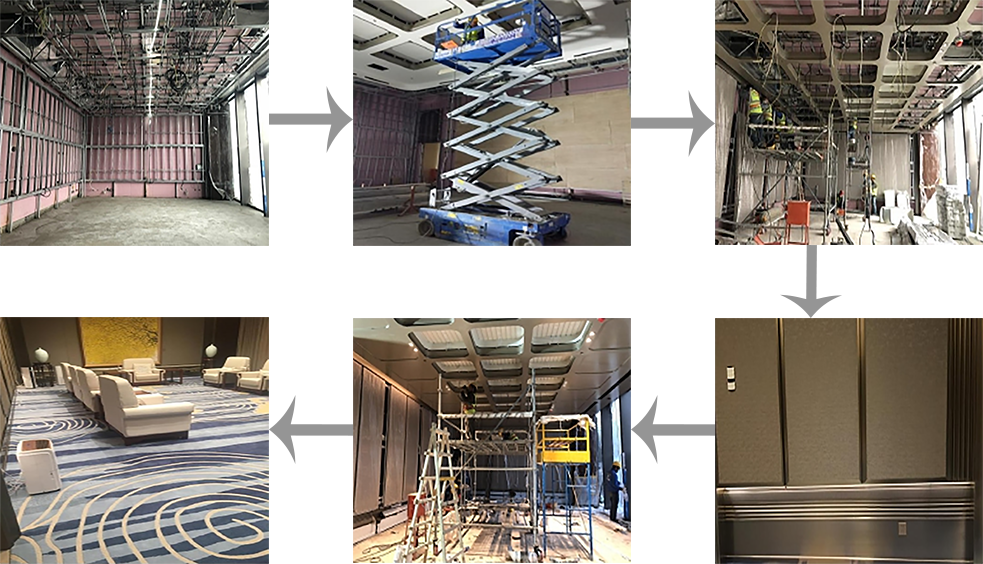

7, assembly installation

Finished installation process

8, difficult to change bright spots: (to ultra-high door for example).

1) Optimize the front and rear field ratios:

Reduce the construction content of the site, increase the number of backfield productization, modularization.

Red site construction, blue backfield product construction

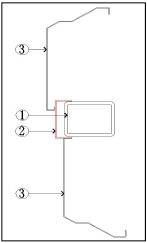

2) Optimize the process order:

The door frame part places an order before the door cover does not delay the installation of the door fan, effectively guarantees the continuity of the wood finish operation, and works of the Concorde construction.

(1) door fan fixed steel frame positioning;(2) door sleeve stop to place an order;(3) door cover line field The order is placed under the gauge.

(1) Door cover port installation (2) Installation door fan (3) door sleeve installation

3) Optimize the installation and construction program:

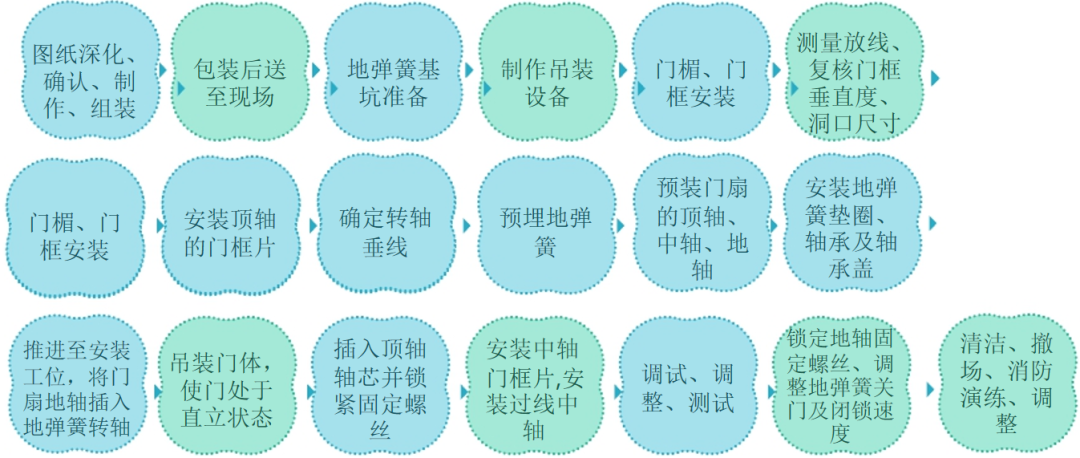

The over-gate installation process

More than three days in advance to do enough to withstand the weight of the copper door concrete pit, copper door weight 900KG, the bottom of the pit should be left about 12mm cement grout layer to ensure sufficient leveling space and grout layer cement strength.

Optimization measures for pre-buried springs

Optimization measures for over-gate installation:

Copper door installation is completed under the empty 10mm, above the empty 7mm, copper finished door (with the copper door to form the whole picture) high out of the fan distance is very small, in the lifting process specially equipped with 2 lifting safety personnel, keep an eye on the finished product protection in the lifting link.

Actively listen to the views of the workers master, the use of hoistway installation, efficiency festival.

03

Live reality view