Bulk hardcover | Do these 20 management / prevention and control elements with your heart, and never worry about difficult delivery!

01

Establish standardized systems and processes

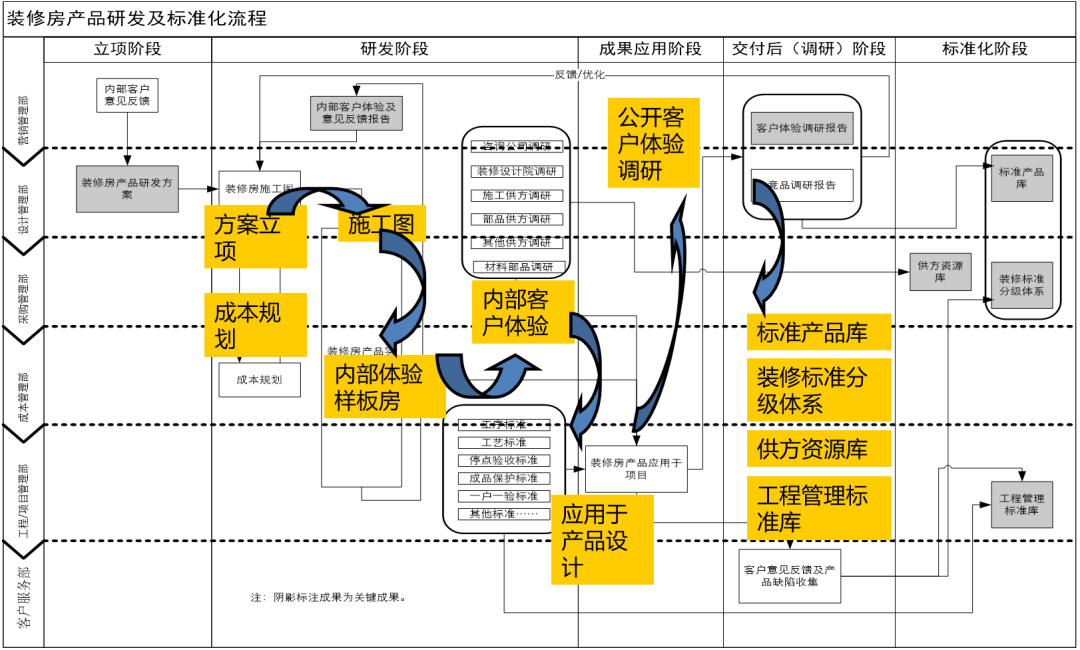

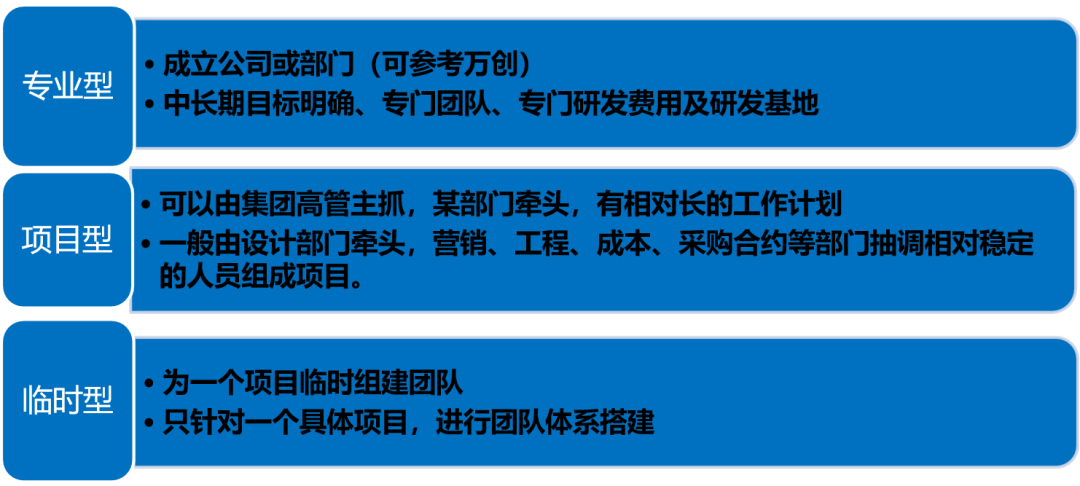

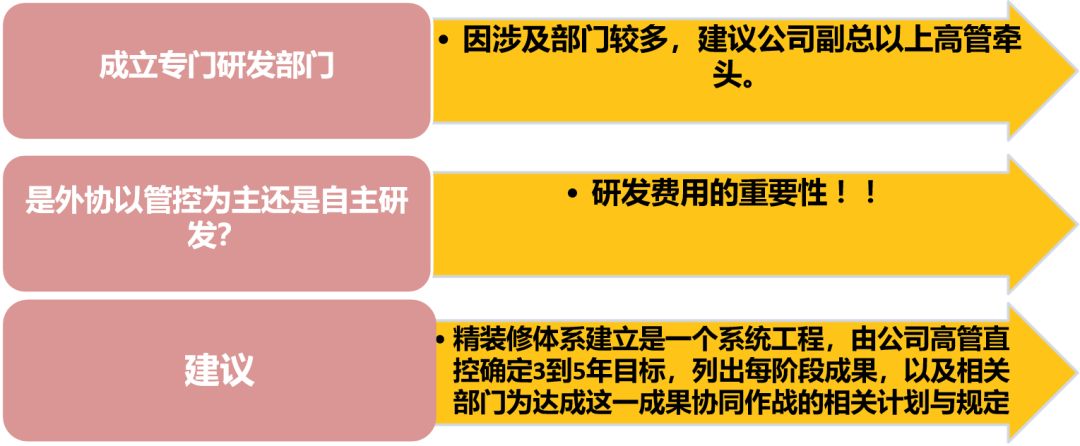

1, batch fine decoration organization system

National or regional group companies recommend the establishment of hardcover research and development departments, integration of internal and external resources, to create core products.

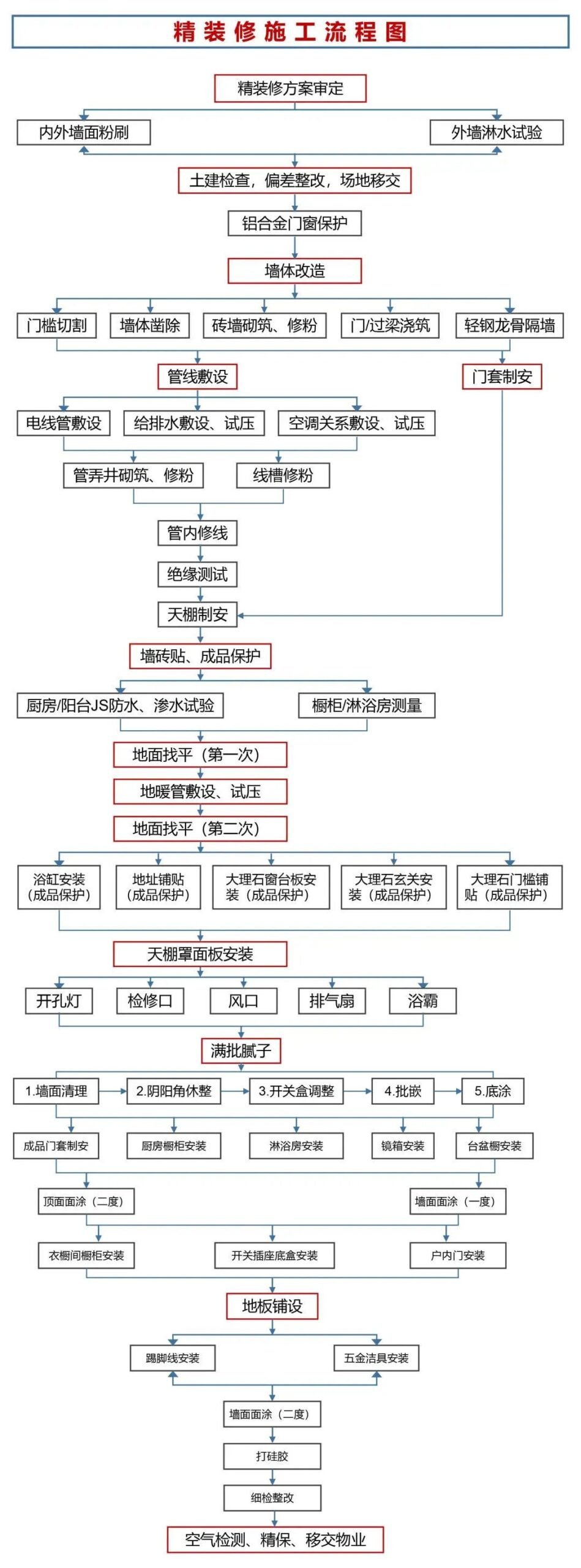

To do a good job of fine decoration, not only to control costs, rush the duration but also to protect the quality, for the project team is a great test, wherein the process index is the key to the entire project management logic! So before we begin, we’ll sort out with you the entire workflow of fine decoration.

02

Improve internal control support, multi-sectoral co-operation

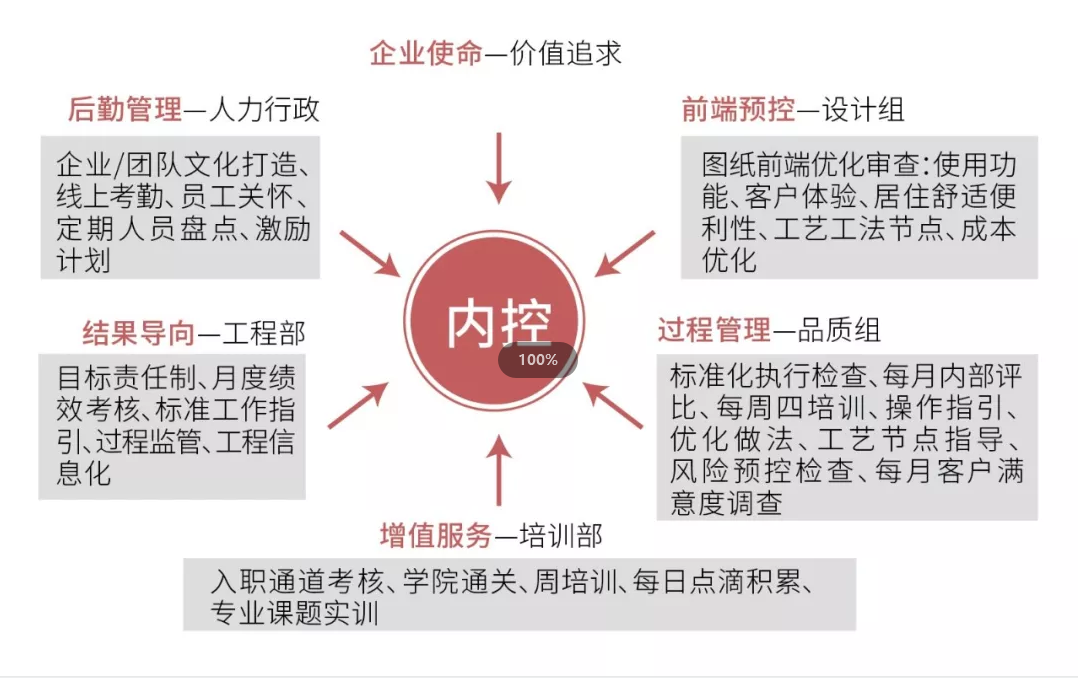

If the project department alone to complete the project, too much power and too much empowerment easy to cause problems, enterprises need to improve internal control support, through the background to complete training, the establishment of engineering standards, and other standardized support. In addition, enterprises should strengthen the collaboration among departments, break down departmental barriers, promote information sharing, and enhance collaboration capabilities.

Enterprise internal control support

03

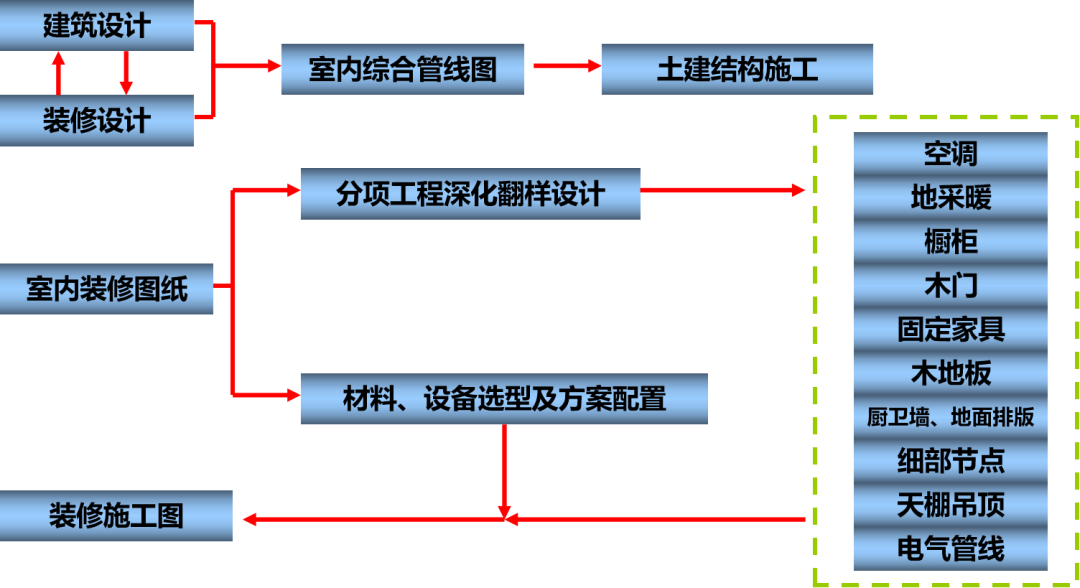

Pre-design, risk pre-control review

By reviewing the functionality of pre-controlled project use, customer experience, comfort and convenience of residence, security risks, drawings, node optimization, missing errors, etc., we can effectively improve customer perception and use it as a starting point to address the project pain points from the front end.

Use features and customer experience: Include functional, usable design flaws to reduce the number of changes in the project process and reduce the cost of pre-delivery rectification, reduce post-delivery customer complaints, and improve overall project customer satisfaction through pre-screening.

Security risks: Through pre-screening, to avoid the project’s design defects, errors caused by security risks.

Fine review: through the project (including construction, structure, water supply and drainage, strong and weak electricity, HVAC and special designs such as doors and windows curtain wall, hardcover, landscape, and another professional) drawing fine audit, check the professional and professional errors and gaps, design depth, normative provisions, drawing standards, real estate standards, and other issues, to reduce the overall project cycle, reduce project costs, improve drawings and project quality and other effects.

04

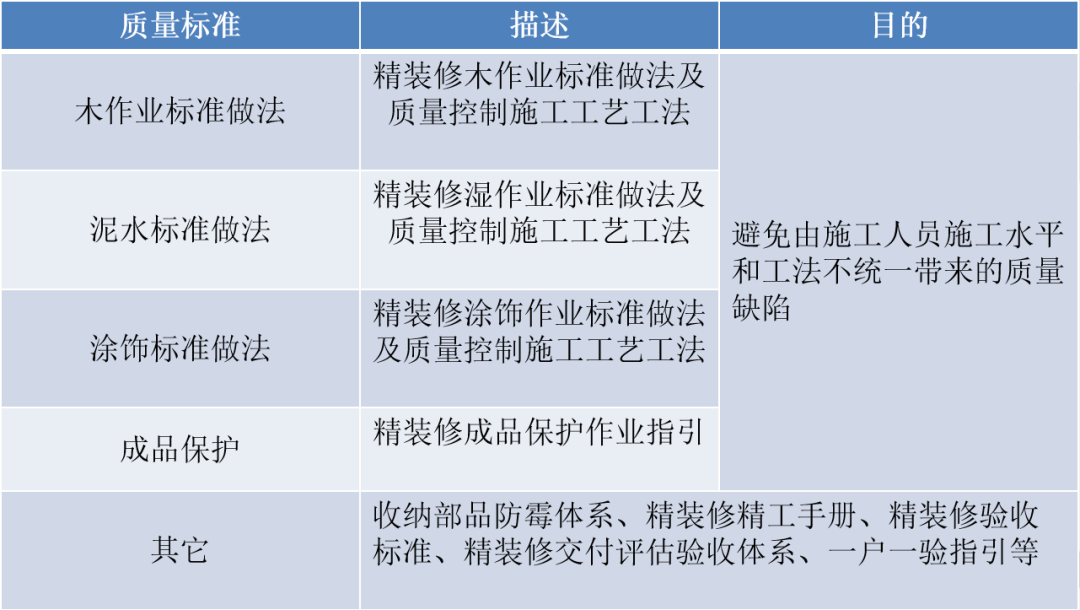

Technical standards established: standard engineering quality

At present, in the current industry, the prevalence of hardcover repair standards, lack and unclear, subjective, judgmental, and other issues, are more difficult to avoid.

However, by establishing and refining enterprise project standards to fill the gaps and deficiencies, we can improve the technical standards, standardize the operation and ensure the quality of the project.

Refine the enterprise standards

05

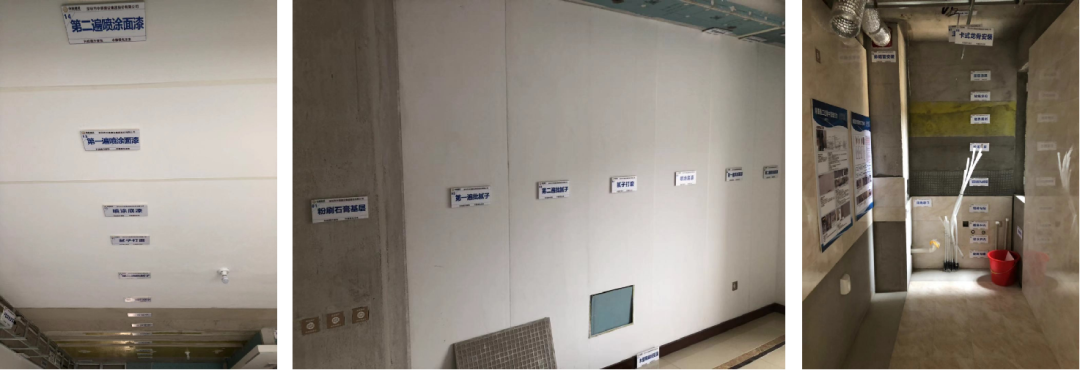

The model first: strengthen the control of materials, processes

Enterprises can pass three models first, put an end to customer litigation risk, improve the satisfaction of owners. In general, the model includes the following first during construction.

Solid model: By presenting the solid model and jointly reviewed by the responsible parties of design, procurement, cost, engineering, and construction, the unreasonable or wrong places are optimized and corrected, and the standards of product output are guided.

The process method model: unified construction quality standards, requiring each construction team to carry out construction according to this standard.

Paint the gypsum process / measured amount

Smallpox keel process/window sill stone process/window sill stone closing process

Ceiling latex lacquer process/wall latex paint process/wall brick process

Ground leveling process/floor tile process/wood flooring process

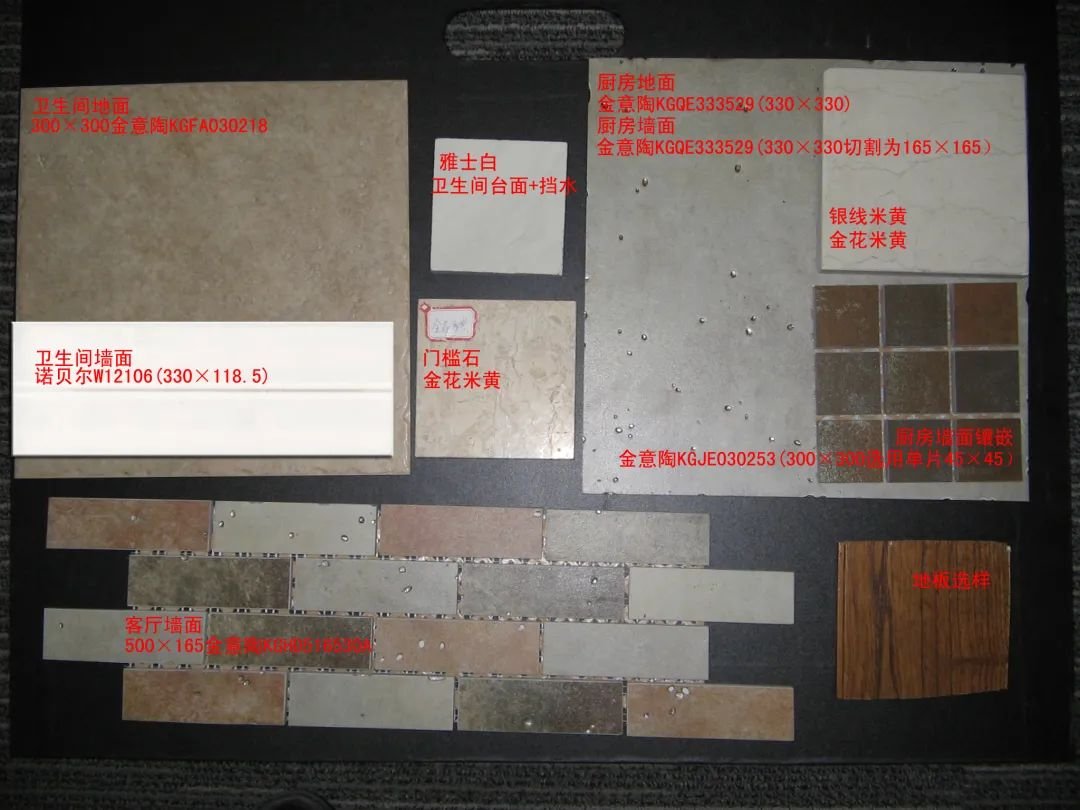

Material model: clear material allocation standards, the formation of design seal samples, guide the bulk construction material standards.

06

Worksurface handover: to solve the “defects” of poor quality at the grass-roots level

Overall, the following problems are prevalent in the current industry:

1, before the handover of civil construction and fine decoration units, fine decoration and subcontracting units to pull;

2, after the occurrence of quality problems each other, can not determine the responsibility of the main body, often developers when the wrong head, seriously affecting the duration and quality.

However, in the process of hardcover repair and construction, it is often due to the lack of corresponding work surface handover standards, incomplete basic inspection, incomplete problem rectification, unclear division of transfer responsibilities, resulting in quality problems at the time of delivery or after delivery.

Based on the above issues, the following measures can be taken:

Establish systematic handover standards and contents: Where there is a work surface connection between the general sub-contract and the owner subcontract or the owner’s direct subcontracting and direct subcontracting unit, the work surface handover is required, and the transfer standard is formulated following this standard for acceptance, such as super-standard or other special requirements, should be promptly proposed and implemented after consultation and consent of the relevant parties.

Leading work surface handover process management: The handover process is following the “Submit handover confirmation form – receiving unit advance on-site inspection and notification of supervision – handover of both parties/supervision /. Owner on-site handover (on-site signature confirmation)- written handover procedures” carried out.

Preparation, supervision, and implementation of the transfer federation sign: divide the owners, supervision, transfer units, receiving units of the 4 parties responsible for the main body, clear authority and responsibility, in the transfer of the Federation sign.

07

Covert acceptance: to ensure that there is no hidden danger

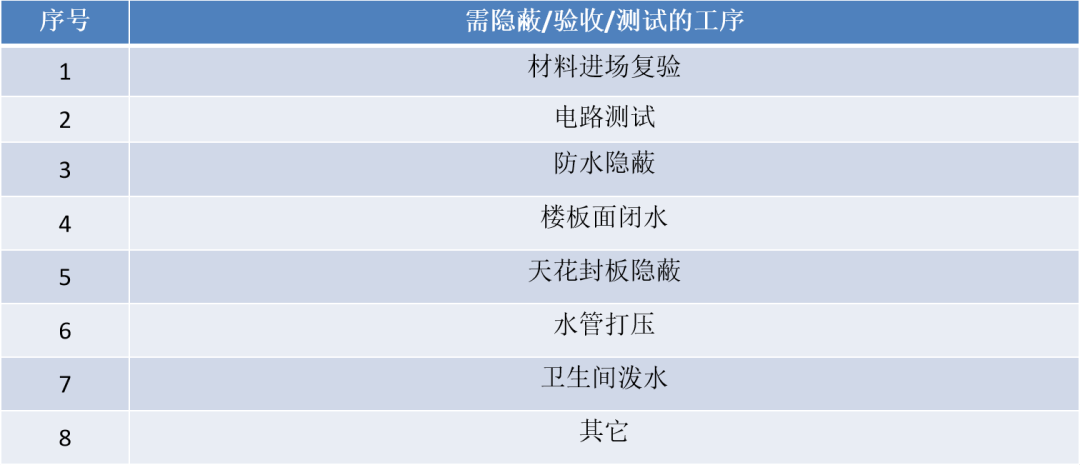

After the completion of the hidden project, must pass the acceptance, to ensure that there is no hidden danger, qualified can continue construction, the following picture is part of the acceptance process.

For all possible problems, according to the acceptance criteria, and customer demand as the starting point, through the relevant transfer of content deepening, refinement, and improvement, avoid risk sources, do a good job of hardcover process quality control.

Part of the acceptance process

08

Progress management: implement visual, quantifiable dynamic management ideas

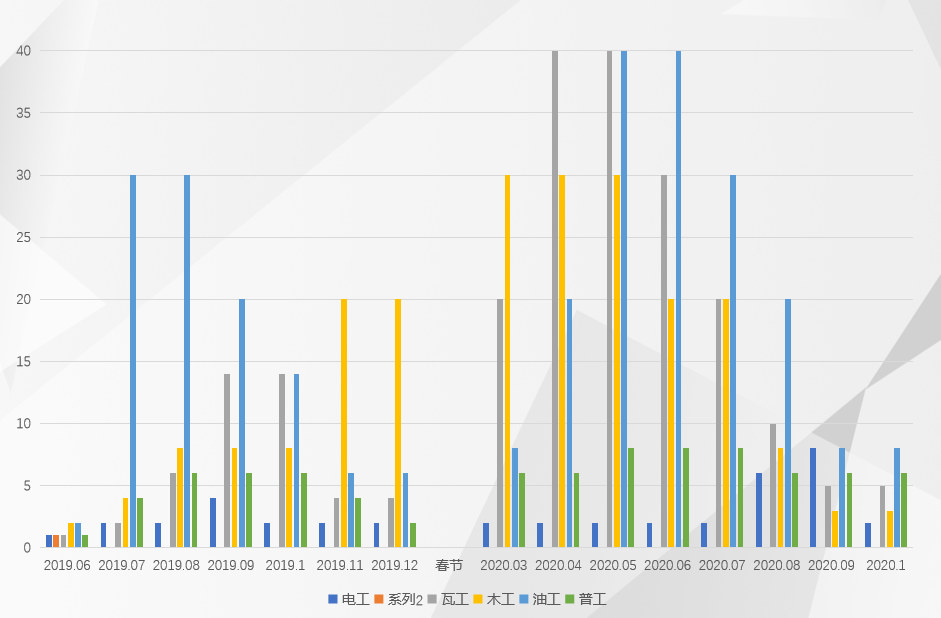

Quantifiable refers to the amount of engineering, engineering efficiency, and manual rationalization of labor through scientific calculations.

Labor Plan

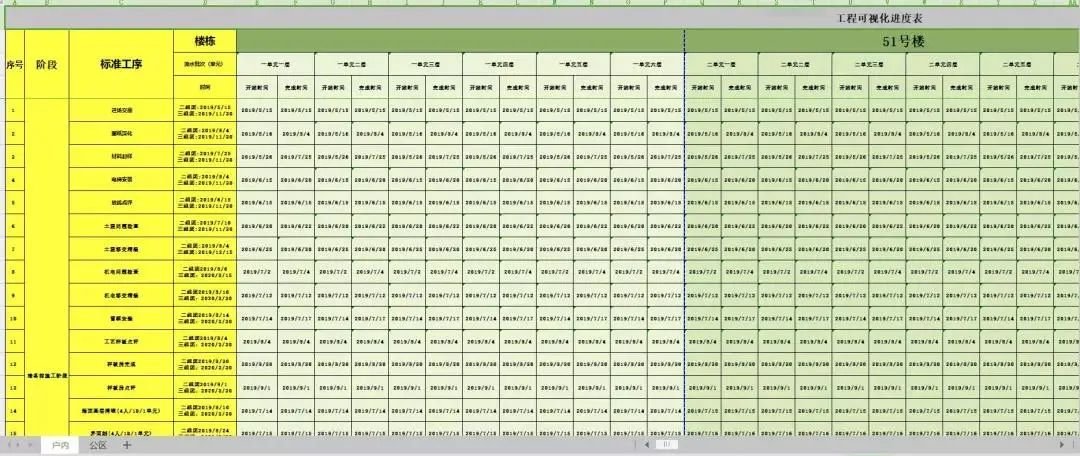

Visualization has been gradually promoted and improved in the industry, to achieve management transparency, can find problems promptly, solve problems. The progress visualization control table for the following image, where each operation plan completion and actual completion time at each layer is visible and the overall picture is dynamic and visual.

The combination of the two, do a good job of progress control, improve pre-controlled, dynamic, more intuitive progress control ideas and programs, reasonable and orderly scheduling and implementation of the schedule, strengthen project planning, organization and operation, resource coordination, on-site management, and implementation and supply chain control capabilities.

Visual progress control

09

One household, one test: put a good last quality pass

Review pre-controlled project usage features, customer experience.

From “three no products” to “ten products”, before delivery to the small owner’s perspective on the set of acceptance, for defects to carry out an article by article rectification and quality improvement, for small owners to put a good last quality pass.

A list of household-to-house data checks

10

The introduction of information tools, the whole process of leaving traces normal

With the development of science and technology, intelligence is gradually applied to the real estate industry and promotes the level of building intelligence to further improve.

In the field of construction management, with the help of intelligent APP, through intelligent process acceptance, measurement, material testing, and other online office functions, in a paperless office, improve work efficiency at the same time, but also through information scars, regulate on-site behavior.

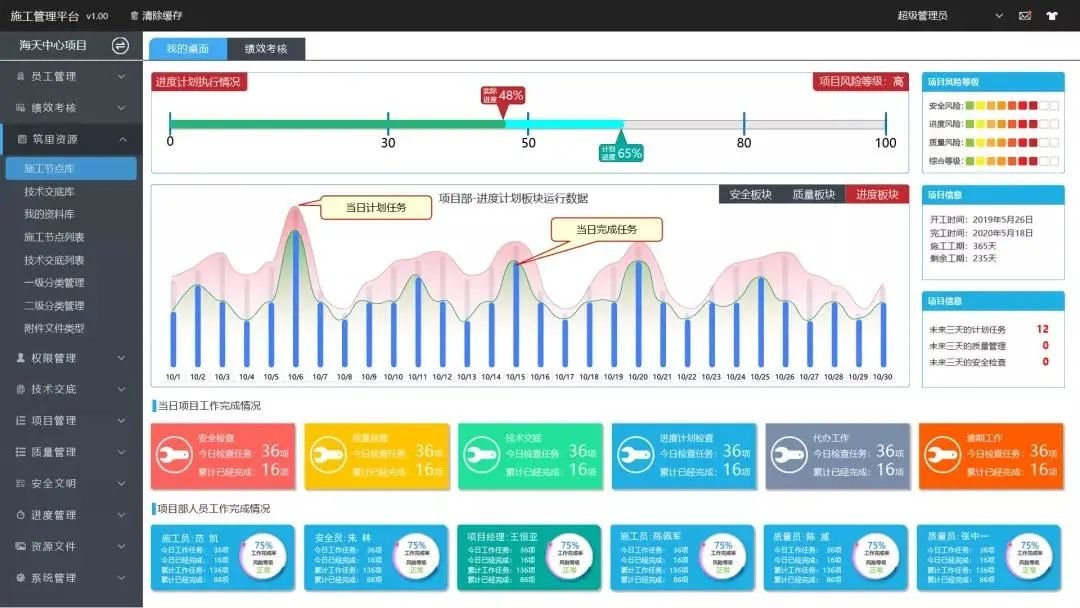

Tsukiji project control platform, to help decorative construction enterprise project fine construction, digital management. By taking the lead in building a digital project management platform for construction enterprises, all projects under construction are dynamically monitored in real-time and timely feedback on quality problems and safety hazards. Engineering management personnel can keep track of all site distribution, scores, warning information through a single map.

Click on the image to see more information

At the same time, through the project interoperability of security, bottom, quality, progress data comparison, to assist project managers and business managers decision-making analysis, to improve communication and decision-making efficiency!

Click on the image to go to the trial page

Tsukiji Project Management Platform Trial URL:

http://xm.xinzsd.com

The top 10 management methods shared above, share with you the top 10 quality prevention and control points for hardcover processes, detailed regulations, and innovations from the continuous improvement of the process experience of project front-line engineers.

01

Leak-proof management project

Waterproof grass-roots engineering

Technical standards: hanging hole layered pouring seal, pipe root waterproof grass treatment smooth, waterproof grass-roots smooth, yin and yang corner do not leave ash, do not leave pulp, set R corner; Can not appear segmented stitching, bathroom threshold stone, shower threshold stone and grass-roots stone between the water-resistant blocking, the grass-roots drying can be waterproof construction.

Quality risk requirements:

1, reserved hole blocking is not in place; Tube root waterproof basic treatment is not smooth, there are sand eyes, hole phenomenon;

2, indoor waterproof grass is not smooth, not cleaned up;

3, the threshold stone is not first, the grass-roots yin angle is not set R angle;

4, the grass-root is not dry that waterproof construction.

Note: Hardcover waterproofing works are mainly aimed at kitchens, bathrooms, balconies, and other waterproof parts.

Waterproof coating engineering

Technical standards: waterproof brush thickness, height, range following the requirements of the process method standards, construction requirements (general wall floor back 300mm, shower wall back 1800mm; kitchen bathroom basin sink back and side wall turn 1000mm), set up anti-entry facilities within 48 hours of the completion of the waterproof brushing, pay attention to timely maintenance to prevent cracking, and water testing is required after waterproofing is completed, more than48 hours.

Quality risk requirements:

1, waterproof coating film there are bubbles, slag, cracking, thickness did not meet the requirements, footprints, powdering phenomenon;

2, waterproof brush height, the range does not meet the design or process technical standards;

3, waterproof brush after completion of 48 hours without setting up anti-entry facilities;

4, no protective layer set up for the next operation construction;

Note: Coating thickness test method: Cut 20mm × 20mm real sample measured with several cursor calipers.

02

Wall tile/stone engineering

Typographical engineering

Technical standards: non-whole brick should be laid on both sides of the yin angle or furniture below, single-sided wall floor should not have two columns of non-whole brick, non-whole brick width is not less than 1/3 of the original brick; Hyunguan to the sofa position row brick, kitchen bathroom floor can be rowed brick from one side, mosaic must be laid in the form of the back panel, corner mosaic size is not less than 2/3of a single grain, kitchen bathroom without ceiling, wall tiles from the roof to leave about 50mm wide flat gap.

Quality risk requirements:

1, before the placement, did not carry out the model layout;

2, single-sided wall floor has two columns of non-integrated brick, non-whole brick width is less than 1/3 of the original brick;

3, the floor brick has a seam toward the sky, the size of the head;

4, type layout, pattern stitching layout error, foyer, living room from one side to start the patch.

Color difference and processing control

Technical standards: Any batch of tiles/stone into the field, spread out in the open space 10m2,2m line of sight, to determine whether the material color difference and check whether the processing size is accurate; To prevent the appearance of exterior stone color inconsistency, when laying should be carefully selected and tried on stone.

Quality risk requirements:

1, tile/stone damage, upturn, size is not the same;

2, tile / stone color difference;

3, processing caused corner collapse or not straight, processing sea otter angle and other rough;

4, the stone did not do six-sided protection.

Stoneground collage craft

Technical standards: less than 200mm wide stone prohibited on-site stitching, the stone floor should use sealed collage, stitching with the same color glue repair, after grinding for crystallization treatment, crystal brightness did not reach more than 90 degrees; When there are soft and hard bags and wood finishes on the stone floor, the wall roots should be moisture-proof treatment. The stone paving pattern is clear, color consistent, seam uniform, mosaic is correct, pattern symmetry.

Quality risk requirements:

1, stone plate surface pollution, fracture, scratching, breakage, repair marks obvious, yang angle treatment is not clear;

2, stone-ground glue color and stone is not the same color, crystal brightness did not reach more than 90 degrees;

3, different material junctions at the mouth rough, not straight, the use of putty to fill the gap, poor quality of perception;

4, stitching pattern error.

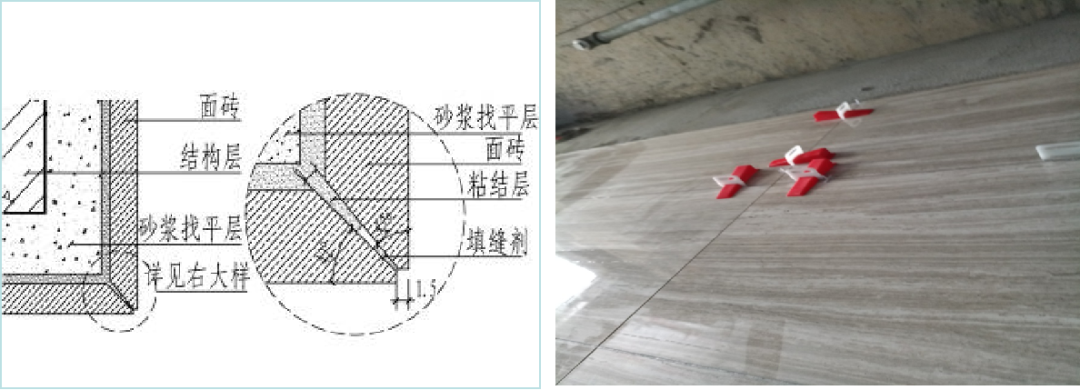

Tiles/stone left seams, yang angle stitching article

Technical standards: To effectively control the width of the seam, the paving must be in conjunction with the plastic cross card construction, such as design no requirements, floor tiles off the seam patch, reserved gap 1.5to 2mm; 45-degree angle, polished brick 3 x 3mm sea otter angle, tile kick line yang angle using small sea otter angle(1.5mm), prohibited the use of the original edge closing.

Quality risk requirements:

1, the material junction at the mouth rough, yin and yang angle is not straight, the use of putty to fill the gap, poor viewing quality;

2, the seam is not full, not beautiful, the surface pollution is serious;

3, stone yang angle 45 degrees stitching, yang angle is broken;

4, tile Yangjiao original edge closing.

Department of installation perception

Technical standards: wall reserved pipe tiles need to apply special tools to drill round holes, not to cut the wall tiles after collage; The direction of return water is obvious.

Quality risk requirements:

1, ground leakage, switch box and other places open too large, rough, black leakage, cross-seam installation;

2, the surrounding seams are uneven, the depth is not consistent, the surrounding is not straight, the mosaic is not correct;

3, the ground leakage did not find a slope, the flowing water is not smooth.

03

Putty, painting works

Grassroots Engineering

Technical standards: pipeline slotting width is d*n s20mm≤ slotting width ≤ d*n s60mm,pipelineslotting depth is d s20mm≤ slotting depth ≤ d s40mm; Root tube above) and other settings anti-cracking wire mesh; anti-cracking wire mesh width is not less than 300mm or junction width is not less than 100mm; Sealed tight.

Quality risk requirements:

1, pipeline slotting site, mechanical slotting, slotting width, and depth do not meet the requirements;

2, hole, line groove, and other parts of the anti-cracking measures to deal with;

3, slotting depth, width is insufficient to cause pipeline exposed, greater than 35mm unlayered blocking;

4, the large surface of the wall sand, return alkali and other phenomena.

Putty Engineering

Technical standards: wall bullet line, plaster flat, putty batch embedded flat (flatness 4mm before grinding); Angle with the ruler and fine sandpaper grinding (flatness after grinding 3mm), to prevent anglecollapse, yin and yang angle straight line degree control within 2mm;

Quality risk requirements:

1, uneven walls, pollution, cracks, sand eyes, permeable bottom, drumming of the powder, moisture mold;

2, Yin and Yang angle is not square integrity, there are bumps, broken corners;

3, wire boxes, filing cabinets, lamps, and other junctions around the opening uneven straight, leaky black, rough wall openings.

Paint painting works

Technical standards: no exposed wire mesh, steelhead, no color difference, no peeling, cracking, etc. ;

Quality risk requirements:

1, paintbrush marks obvious, wavy, flowing, permeable bottom, obvious color difference, cracking, etc.

2, switch panel and other materials around the junction rough closing;

3, tiles, wooden floors, kick lines, doors, and windows, filing cabinets, switch sockets, pipes, etc. are contaminated by paint, bite color.

04

Ceiling, wood base project

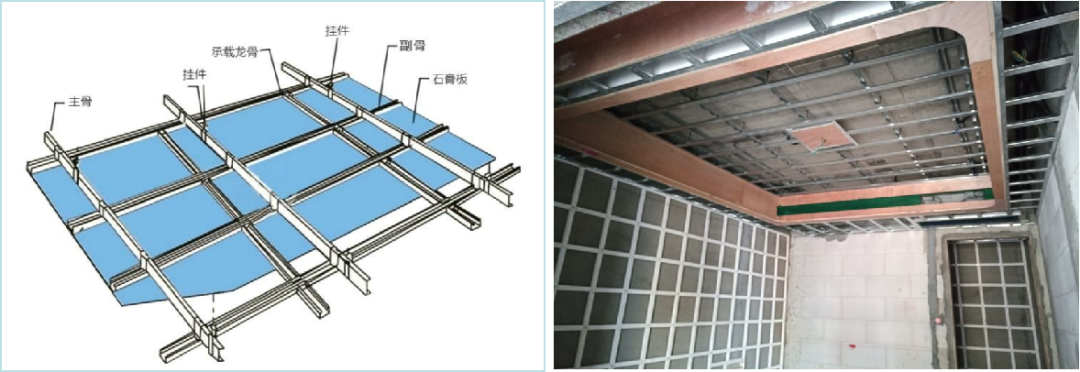

Boom Engineering

Technical standards: the hanging rod before installation to lay the line to mark the position, the boom before installation cutting size is generally uniform, the parts are well equipped, along the main keel direction of the boom spacing 900-1100mm, at least 1 boomer square meter, the length of the boom is greater than 1.5m need to be set up 30 30 hot galvanized angle steel for reverse support;

Quality risk requirements:

1, the ceiling before the installation of the boom did not carry out the bullet line marking position, boom expansion bolt / the screw there is exposed, bolt loose phenomenon;

2, along the main keel direction of the boom spacing, is greater than 1.1m, the boom is too short, the installation is not secure, the upper and lower screws are not fastened, and the boom is bent, not vertical, rust and other phenomena;

3, the length of the boom is greater than 1.5m when not set 30 x 30 hot galvanized angle steel for reverse support reinforcement treatment.

Note: Before installation, the room net height, hole height, and ceiling pipe, equipment, and the height of its bracket should be checked according to the design requirements.

Keel Works

Technical standards: wood square or large core plate (including wooden wedges) for three anti-treatment, the use of 50 series main keel, installation spacing is not greater than 900mm, the use of card keel, installation spacing is not greater than 600mm, the first main keel from the wall spacing is not greater than 300mm The main keel pick is not greater than 300mm; the edge bone self-tapping screw is fixed, the nail distance is not greater than 300mm, the wooden end is a fixed point, and the heavy-duty chandelier site is reinforced.

Quality risk requirements:

1, the material (including wood wedges) did not carry out three anti-treatment;

2, the edge keel before installation did not put the wire, did not use wooden wedges or swelling bolt fixed, screw spacing is greater than 300mm, the use of gun nail fixed;

3, the use of card-type keel, installation spacing is greater than 600mm, the first main keel from the wall spacing is greater than 300mm;

Note: Heavy lamps, fans, and other heavy equipment are strictly prohibited from being mounted on the keel of the ceiling project.

Gypsum board engineering

Technical standards: the seams between the double-layer gypsum board should be staggered(300mm), the two layers of gypsum board should be covered with white latex; Side planks larger than 200mm to do swallowtail splicing treatment; Nail eye for rust prevention treatment; no warping, cracks, peeling, missing angle, dirt and defects.

Quality risk requirements:

1, gypsum plate seams did not do plate seams, corners, and other parts of the anti-cracking treatment, plate seams vary in size;

2, gypsum board installation nail distance does not meet the requirements, nail eye did not do rust treatment;

3, lamps, smoke sensors, spray head, air mouth tweezers and other equipment, unreasonable location cutting is not neat, and the handover of the trim panel does not match, not strict.

Note: Before sealing the gypsum board, the following hidden project ceiling pipes, equipment installation and water pipe test pressure, duct tightness for acceptance

Metal buckle plate and air outlet engineering

Technical standards: window roof finish surface elevation should be lower than the ceiling finish surface height, wall brick first paving, paving height higher than the ceiling finish surface height of 10cm, the angle of the edge strip using 45 degrees stitching, corner strip, and tile closing is strictly prohibited glue The buckle plate ceiling opening needs to be carried out on the ground, it is strictly forbidden to buckle the plate after the installation is completed before the opening, consider the ceiling force, plate reinforcement, the ceiling air vent tweezer position is reasonable, the use of finished wind outlet and the finished panel handover coincides, strict.

Quality risk requirements:

1, kitchen and bathroom ceiling plate does not use metal buckle plate, did not use a waterproof plate , waterproof putty, waterproof paint;

2, the window roof finish surface elevation should be higher than the ceiling completion surface height;

3, metal buckle plate deformation, different sizes, color difference, rough opening;

4, metal buckle board is not smooth light installation;

Door covers, background walls, and other grass-roots works

Technical standards: materials to do a good job of three defense (corrosion, fire, insect resistance) treatment; Door cover base slab (concrete wall) using the U.S. solid nail spacing 300mm fixed, if the lightweight partition wall hole side is not set cement Bricks are bolted to the wear-through bolt with a 30-by-30-by-thick 3mmthick (thickness must not be less than 2mm) and a background wall wood base panel 20-30mmoff-ground to prevent moisture.

Quality risk requirements:

1, wood grass did not do a good job of three anti-corrosion, fire, insect control) treatment, and uneven brushing;

2, door cover base plate (concrete wall) did not use the United States solid nails in the door cover side fixed and unreasonable spacing;

3, light steel keel to do skeleton, the center spacing of the secondary keel, plate nail spacing does not meet the requirements;

4, the plank uses a direct stitching method, the anti-cracking part of the treatment is not in place.

Note: Pre-installation acceptance of hidden works: installation of equipment pipelines and water pipe test pressure in skeleton partition walls; fire and corrosion treatment of wooden keel; pre-buried or pulled ribs; keel installation; setting of filling materials.

05

Electrical equipment installation works

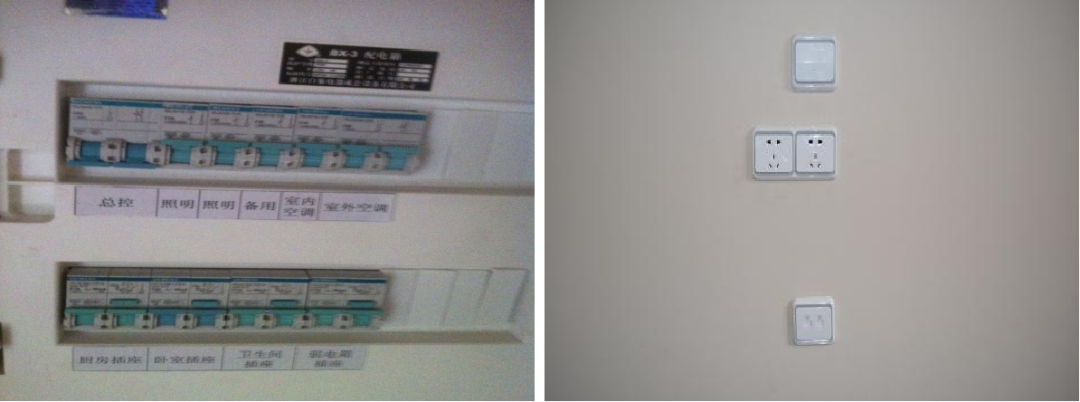

Strong and weak electric box, switch socket installation

Technical standards: the backbox is lower than the finish layer of more than 10mm, the need to set up a thickened back box; Adjacent switch socket back box should be used in the backbox; The same model side-by-side installation and the same indoor switch installation height consistency, parallel socket switch panel height difference is not greater than 0.5mm; leakage switch short-circuit protection, Reliable overload protection action; The wire color standard is reasonable, the wiring is correct, the left zero right phase; The circuit number in the distribution box is complete and the identification is correct.

Quality risk requirements:

1, switch, socket panel, and wall gap is obvious, the installation is not secure, surface pollution, fragmentation, scratching, the decorative cap is not complete;

2, the circuit inside the strong electric box is incorrect, there is no identification;

3, switch socket phase sequence test is not normal;

4, balcony, toilet, and other water parts socket no splash box.

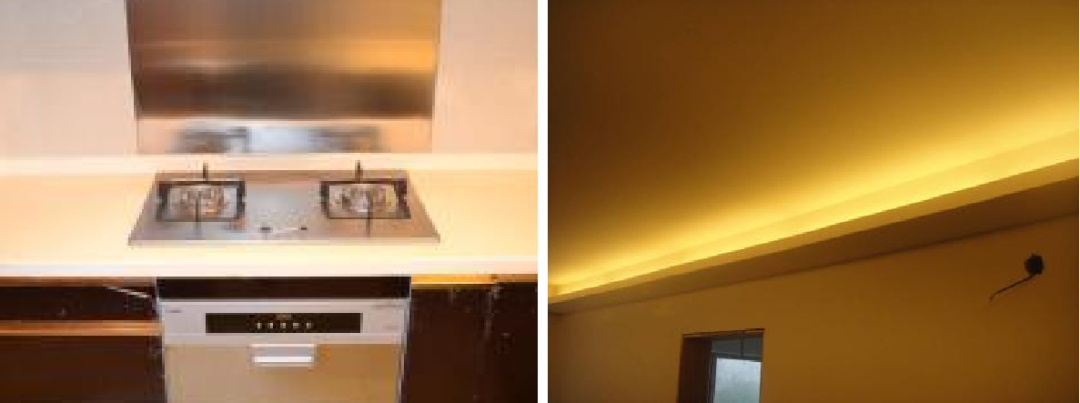

Lamps, electrical installation

Technical standards: lamps and accessories without mechanical damage, deformation, coating shedding, and lamp cover rupture and other defects; Electrical installation must avoid the water pipeline position of more than 100mm, to avoid damage to the water pipe, it is strictly prohibited to use large glass cover lamps, to prevent glass cracking and splashing down.

Quality risk requirements:

1, lamps around the leaked black, rough closing, scratches, pollution;

2, lamp installation skew fixed is not secure, in rows of installation lamp centerline is not aligned or deviation is greater than 5mm;

3, home appliances installation is not strong, surface scratches, deformation or can not be used normally or not convenient to use;

4, heavy-duty chandeliers are not set up with independent hooks.

Hardware bathroom installation

Technical standards: corner valve, tap installation after the decoration cover and wall seamless, bath cylinder recommended to reserve access, base to do a certain slope, conducive to drainage, sanitary ware water supply pipe no bumps, bends, and other defects, and water pipe, sewage outlet closely connected; water dispenser in the wet area, installed inside the cabinet, on the outside can open the decorative box;

Quality risk requirements:

1, the basin water after installation leakage, drainage is not smooth;

2, hit the glue part, not straight, basin, toilet and other surrounding glue did not use neutral anti-mold silicone;

3, reserved access gate is not set (bath, etc.);

4, the installation of hardware pendants does not use glass drill bits, resulting in tile corners or rough drilling.

06

Wood flooring, kickline engineering

Wood floor mounting

Technical standards: material entry needs to carry out color difference control, flooring before the installation, it is appropriate to transport to the paving room open bag for more than 48 hours, priority in the direction of light discharge, and then perpendicular to the direction of the door discharge, floor laying solid, no loose, walking without noise (the overhead floor is strictly prohibited to use wooden wedge leveling), no size head, joints can not afford to arch, no ash Small kickboards and stitches should be placed behind doors, sofa beds, etc. should not be conspicuous;

Quality risk requirements:

1, the grass-roots did not deal with clean, untreated flat, directly laid;

2, before laying did not check whether there is a color difference;

3, laying is not secure, arch, there is a noise, the gap is too large, the size of the head;

4, wood floor ash;

5, wooden floor and different material junction does not set the demarcation strip, need to do moisture treatment site did not do moisture treatment.

Kickline mount

Technical standards: nail eye weakening treatment, wood kick line plane should be used 45 degrees oblique stitching, wooden kick line stitching height and the low difference are not greater than 0.5mm, kickline installation should be lower than the door face by kick line side of the minimum thickness of more than 2mm, to ensure that kick line and door face seam closed to the angle.

Quality risk requirements:

1, kickline surface uneven cleaning, uneven gaps, height inconsistencies, obvious color difference, scratches, bumps;

2, kickline position has distortion deformation, wall handover is not strict;

3, kickline connector treatment uneven, high and low difference, obvious color difference, nail eye obvious;

4, the kick line and ground gap are too large.

07

Wallpaper wallpaper project

Wallpaper construction article

Technical standards: wallpaper construction, the grass-roots treatment clean and brush the base film, wallpaper stitching, the stitching should be horizontal vertical, yin and yang corner angle is clear, stitching pattern, pattern matching, not off the seam, not tied, the edge straight and neat,1 m face each piece without obvious stitching; Wrinkles, cocked edges, stains, dead wrinkles, chromic aberrations, ripples, ripples, squinting should be without glue marks;

Quality risk requirements:

1, the grass-roots did not deal with clean, did not do moisture-proof mold treatment;

2, color difference: visual detection of obvious color difference, yin and yang face;

3, seams: 1 meter from the wall visual inspection, visible seams;

4, process defects: incomplete flower pattern, deformation, poor flatness; Contamination, scratching, breakage, mold, etc.

Note: The grass-roots putty of wallpapers should be flat, solid, firm, powder-free, peeled, and cracked.

Notes before and after wallpaper construction

Technical standards: before the base film brush, the site needs to be equipped with a water content tester to determine the water content of the grass-roots of the smudge is not greater than 8%, the water content of the wood base must not be greater than 12%, wallpaper entry must check whether there is chromatic aberration, the pattern is clear texture, etc., wallpaper must use the mechanical automatic adhesive machine, mechanical automatic glue, bonding tape, Cut length; wallpaper pasted room should be cleaned in time, not allowed to cook room or lounge, to avoid pollution and damage.

Quality risk requirements:

1, the grass-roots did not dry the start of construction;

2, artificial glue, cutting;

3, wallpaper after the construction of open doors and windows ventilation;

4, wallpaper after the completion of construction as a material room.

Wallpaper construction closing

Technical standards: roof yin angle need to be set gypsum angle line or hanging mirror line end, to ensure that wallpaper closed in the line under the mouth yin corner; aluminum alloy / plastic steel door and window frame, window sill stone and wallpaper yin corner end; indoor the same kind of wallpaper stitching is strictly prohibited to close at the wall yin and yang corner; wallpaper wall and aluminum alloy / Plastic steel door and window frame, window sill stone outside the handover can be fine glue, the rest of the parts are strictly prohibited glue;

Quality risk requirements:

1, yin and yang angle, door window, switch panel and with different material junctions of rough closing;

2, gold and silver foil closing glue;

3, wallpaper after the construction of paint;

4, the same kind of wallpaper is closed in the yin and yang corners.

08

Hard package soft package engineering

Hard-pack, soft-packed wall construction

Technical standards: keel, lining, border installation solid, tight, no warping, stitching, cutting neat, beautiful pattern, the diagonal length difference is not greater than 3mm, the cut, line seam height difference is not greater than 1mm.

Quality risk requirements:

1, there are folds at the corner;

2, the surface has scratches, broken, pollution can not be removed, nail eye clear;

3, the grid seam is not straight, the bumps are inconsistent, the straight line is not smooth, the curve is not smooth, the seam width is not the first-class perception defect;

4, the grass-roots board did not do moisture treatment, the color difference.

Wood-decorated wall construction

Technical standards: the grass-roots board strictly prohibit the use of full-page, slats or wood base between the need to leave a seam 3 to 5mm, to prevent the deformation of the wood-decorated wall; It is strictly forbidden to use mercury mirrors, and to use stainless steel strip closing or kick line closing at the bottom, pay attention to moisture protection.

Quality risk requirements:

1, the back did not brush moisture-proof paint or paste balance paper, did not do moisture treatment;

2, wood line within 2 meters of the connector;

3, wood finish process groove width is not consistent, there is no skin, paint and other phenomena, visually obvious seam is not tight, width and narrow, there is obvious deformation;

4, surface visual detection of obvious color difference, pollution, scratching, bumping, breakage, and so on.

Note: Wood finish has electrical appliances, switch sockets, etc. needs to do fireproof, soundproofing treatment.

09

Admission works

Cabinet body, cabinet door construction

Technical standards: the surface of the cabinet is smooth and smooth, neat angle, no damage, scratches, defects, door panel installation is uniform, cabinet, countertop, and wall floor closing is uniform, appropriate, door panels, drawers open flexible, no abnormal noise The door height of more than 1.8m is set up straightener or reinforced ribs, the door panel opening shall not collide with lamps, kitchen appliances, etc., especially in the corner position, and the embedded cabinet body shall be set up with a closing plate, the width of which shall be greater than 3cmand the widths on both sides should be consistent; The closing plate should be uniform with the wall or cabinet gap, hairless or jagged.

Quality risk requirements:

1, cabinet bottom plate is not set aluminum film waterproof groove;

2, cabinet body no backplate, cabinet on both sides of the closing plate size error is large;

3, uneven door panels, warping, uneven seams of door panels, more than 1.8m of the cabinet door is not set straightener or strengthen the ribs;

4, decorative plate surface there are obvious nail eye, color difference, broken;

5, after installation, there is a use of dysfunction.

Hardware installation

Technical standards: hardware installation complete, solid, correct location, surface rust-free, flower spots, pollution, scratches; Cabinet connection screw unified to do invisible treatment; The depth of the joint groove is suitable for matching, the screw model is uniform, the screw head is flat hardware, the direction of the screw rotor is consistent; The door panel requires the installation of damping rods; The installation of the handle should be vertical or parallel to the door panel, do not choose sharp and easy to hurt hand in hand.

Quality risk requirements:

1, door panel, basket open inflexible, there is a noise, hidden refrigerator door panel and refrigerator door is not linked;

2, hardware surface rust, scratches, and pollution;

3, door handle installation is not horizontal.

Table mount

Technical standards: smooth surface, neat angle, no obvious scratches, front-end angle should be rounded, bonding seams on both sides of the table color, a pattern consistent; The countertop is strictly prohibited to integrate with the window sill stone; The countertop is uniform in thickness and width of the glue line 3-5mm, there is no obvious stitching within the 1.5-meter line of sight of the table stitching.

Quality risk requirements:

1, the countertop stone did not float out of the cabinet door installation or floating out of the length is inconsistent, the outside of the stovetop table is not set water line or water line height less than 5mm;

2, the countertop rear water bar and the countertop bonding is not inverted inner fillet, fillet size is not consistent;

3, the table and wall gap is too large;

4, the basin and the table connection using moisture-prone materials for support.

10

Finished product protection works

Decorative decoration stage

Elevator summoning switch protection standards: Be careful to retain the original transparent protective film during installation to avoid scratching the surface. After the installation is completed and the acceptance by the professional acceptance institution is qualified, the installation unit is handed over to the decoration package, and the decoration package unit is covered with a thickened protective film to further strengthen the protective effect.

Quality risk to:

1, the original protective film was torn off;

2, the surface produces scratches;

3, the use of the corrosive cleaning solution.

Decorative decoration stage

Elevator car, exit yang angle protection standards: elevator car box installation and commissioning completed, by the decoration of the total package unit using PE protection glue full paste (including elevator interlayer door), on this basis with 30 x 40mm wood square to do the base frame,18mm Thick melamine plate full of the seal. Exit Side yang angle with 40 x 40 x 1.5mm thick original silk stainless steel corner (sink screw fixed), the height of the ground to the top 1800mm.

Quality risk requirements:

1, did not do protection;

2, the exit yang angle protection height is insufficient;

3, protect the board off.

Decorative decoration stage

Aluminum alloy doors and windows protection standards: doors and windows frame with a protective film (with a non-polluting aluminum profile of self-adhesive tape paper) full affix, note that the edge of the box should be set aside 10mm unsealed to facilitate sealing or cement mortar inlay. Glass double-sided paste plastic film protection. The aluminum door under carrying uses splints for “U” sheath protection and “L” protection for corners.

Quality risk requirements:

1, glass, the profile is scratched, pollution;

2, the use of aluminum profiles, glass, accessories have corrosive cleaning agent;

3, protection shedding, protection is not strict.

Decorative decoration stage

Tile / Stone Protection Standard: After the tile stone paving is finished and the filling work is completed, clean Dry and finish with suitable size clean paste cotton preparation covered with the floor tile surface, must ensure complete coverage. At the cotton preparation cloth junction and corner, need to be fixed with cloth-based tape. Then, in the cotton preparation cloth covered with plastic cloth or corrugated cardboard, cardboard stitching with transparent box glue paste. Carefully check the integrity of the stitching tape paste, and regularly check for damage immediate subsidies to avoid sand and stone from falling into the stitch.

Quality risk requirements:

1, not fully covered protection;

2, protection shedding, protection is not strict.

Decorative decoration stage

Wood floor protection standards: clean the floor surface, and then full of corrugated board to do protection, using the seal paste fixed, in the room entrance to the ground paste “no water work” warning signs.

Quality risk requirements:

1, not fully covered protection;

2, protection shedding, protection is not strict;

3, the use of blades, art knives, and another shovel scraping to do cleaning, wood floor water.