Hotel decorated with soundproofing

1. Most decorative soundproofing is done only in sound-absorbing fillers and walls Thickening surface kung fu, this hotel acoustic data contains 3 common wall types of 7 special sound insulation solutions to solve the problem of sound insulation essence.

2. From the building sound insulation requirements, 5 acoustic measures such as active wall noise reduction, door and window noise reduction, ground noise reduction processing, equipment noise reduction, etc. are provided.

01

Hotel acoustic design standards

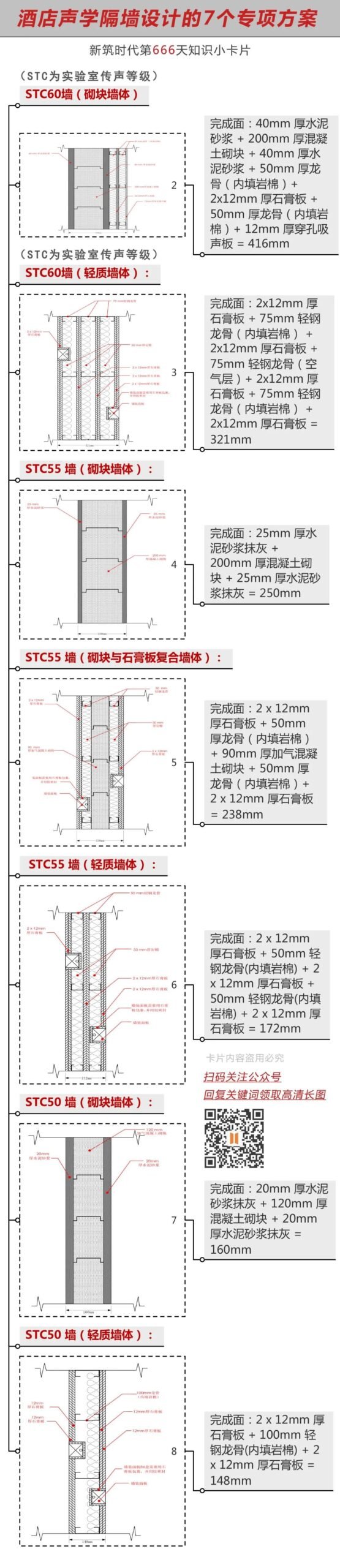

1. In conjunction with the building acoustic standards, develop the soundproofing standards applicable to the hotel:

Noun interpretation: Sound level(STC,in dB).

0 decibels(dB), barely audible sounds, such as the sound of a breeze moving leaves

20 decibels(dB), low murmurs, quiet office sounds

40 decibels(dB), pendulum sound, general office talk

80 decibels(dB), the sound of the street

120 decibels(dB), the sound of the plane’s engine, will make the ear aching sound

The above refers to all acoustic data units in the applicable text

02

Acoustically compliant hotel interior partition scheme

According to the acoustic standards of the hotel above, there are currently 3 kinds of wall construction commonly used: masonry wall, masonry and gypsum board in line with the wall, gypsum board wall, we list the following different sound insulation wall structures, for the owner to choose reference:

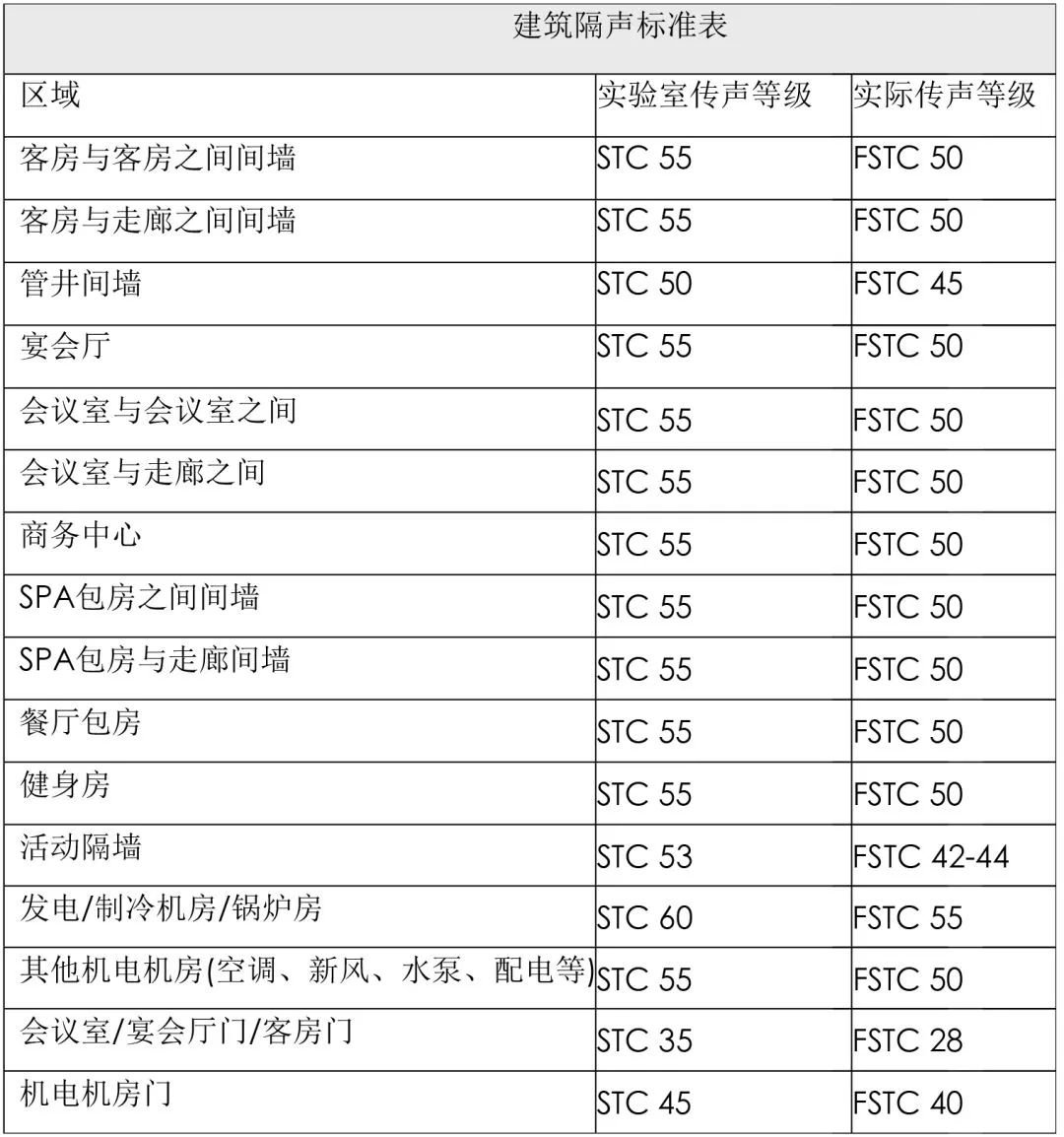

1. STC60 Wall Practice (Block Wall):

(STC is a laboratory sound level, such as STC60, STC50, and so on).

Finished surface:40mm thick cement mortar, 200mm thick concrete blocks, 40mm thick cement mortar, 50mm thick keel (inlaid with rock wool), 2x12mm thick gypsum board, 50mm Thick keel (inner-filled rock wool), and 12mm thick perforated sound-absorbent plate . . . 416mm

Note:

(1) the density of concrete blocks is not less than 600kg, the density of gypsum board is not less than 12kg, and the density of cement mortar is not less than 2000kg

(2) Gypsum board needs to be mis-stitched installation, all boards and plates, the ground and the ceiling between the contact should be sealed with soft sealant edge;

(3) Wall practice should be through the top, can not only achieve the height of smallpox;

(4)Pipeline through the wall location rock cotton filling, and cement mortar sealed;

(5)Perforated sound absorber penetration rate is greater than 18%.

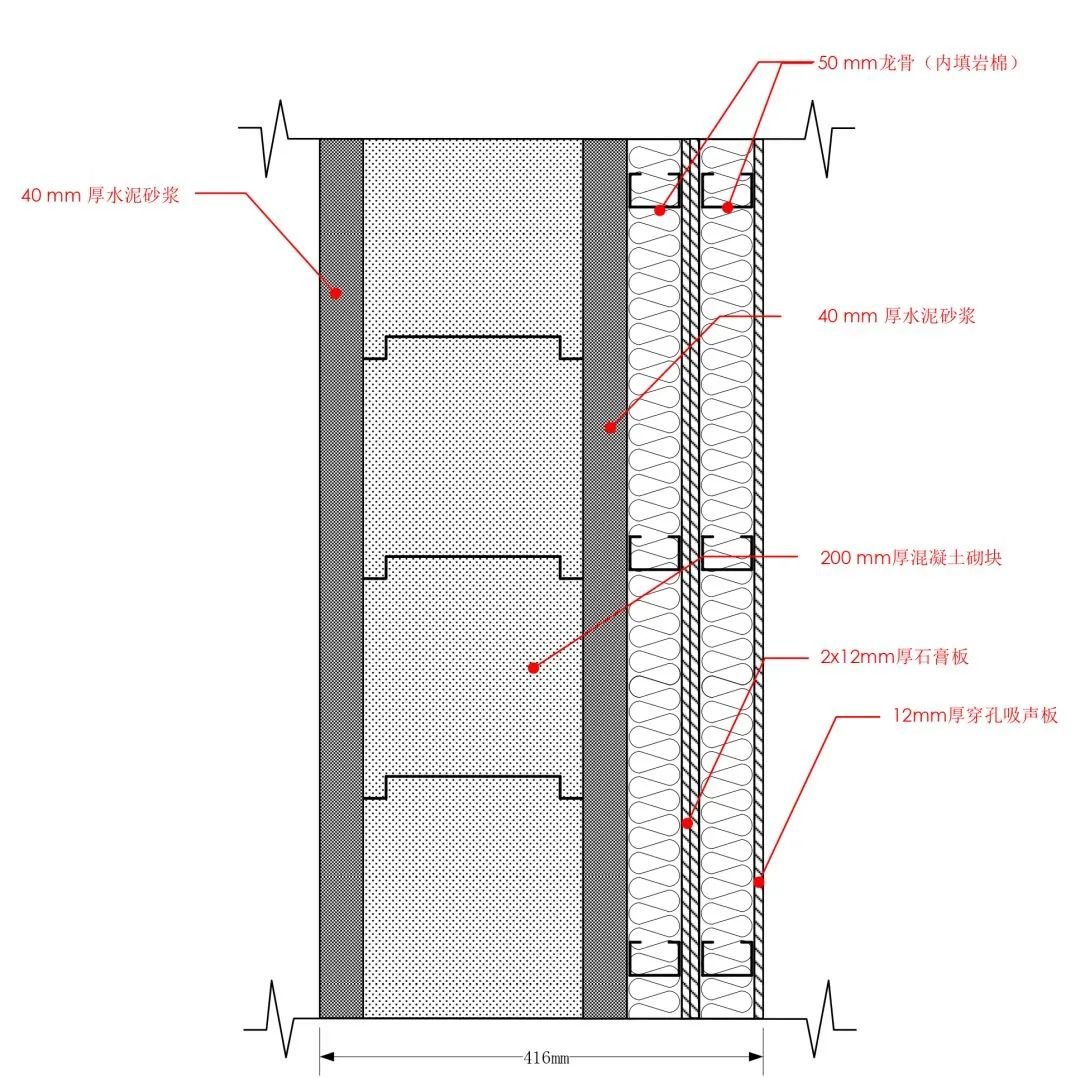

2. STC60 Wall Practice (Lightweight Wall):

Finished surface:2x12mm thick gypsum board, 75mm light steel keel (inner-filled keel), 2x12mm thick gypsum board, 75mm light steel keel (air layer), 2x12mm thick gypsum board, 75mm Light steel keel (inner-filled rock wool) s 2x12mm thick gypsum board s 321mm

Note:

(1) The contents of the rock wool weight are not less than 80kg, and the density of the gypsum board surface is not less than 12kg;

(2) Gypsum board needs to be installed by mistake, all boards and plates, the ground, and the ceiling between the contact should be sealed with soft sealant edge;

(3) Wall panel wire box side and back need to be sealed with gypsum board ceiling, avoid the terminal box back-to-back installation, junction box between at least 600mm.

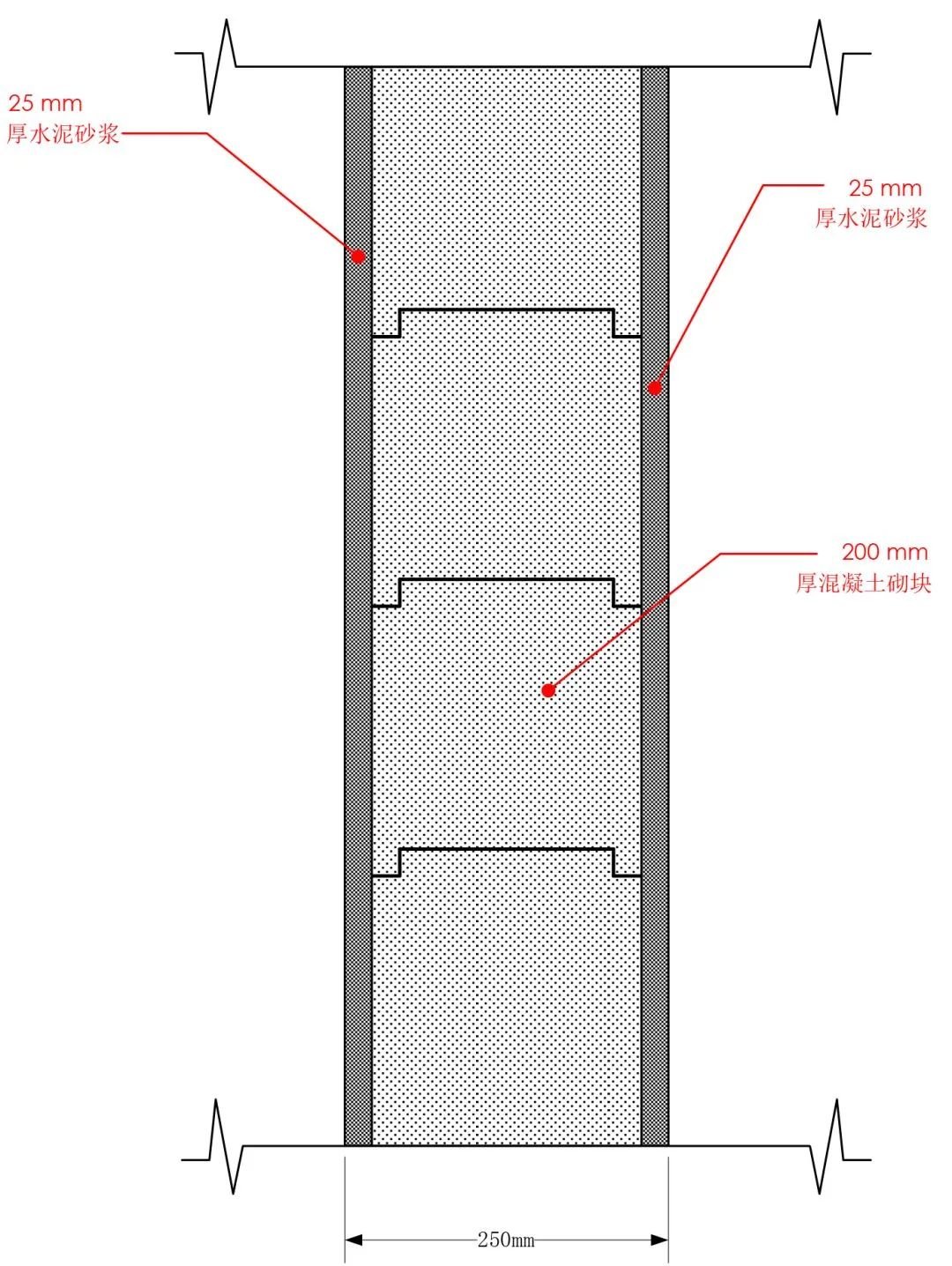

3.STC55 Wall Practice (Block Wall):

Finished surface:25mm thick cement mortar smudged with ash and 200mm thick concrete blocks with 25mm thick cement mortar smudged with 250mm

Note:

(1)block density is not less than 600kg;

(2) Wall practice should be through the top, can not only achieve the height of smallpox;

(3)Pipeline through the wall location rock cotton filling, and cement mortar blocking;

(4) Cement mortar density is not less than 2000kg.

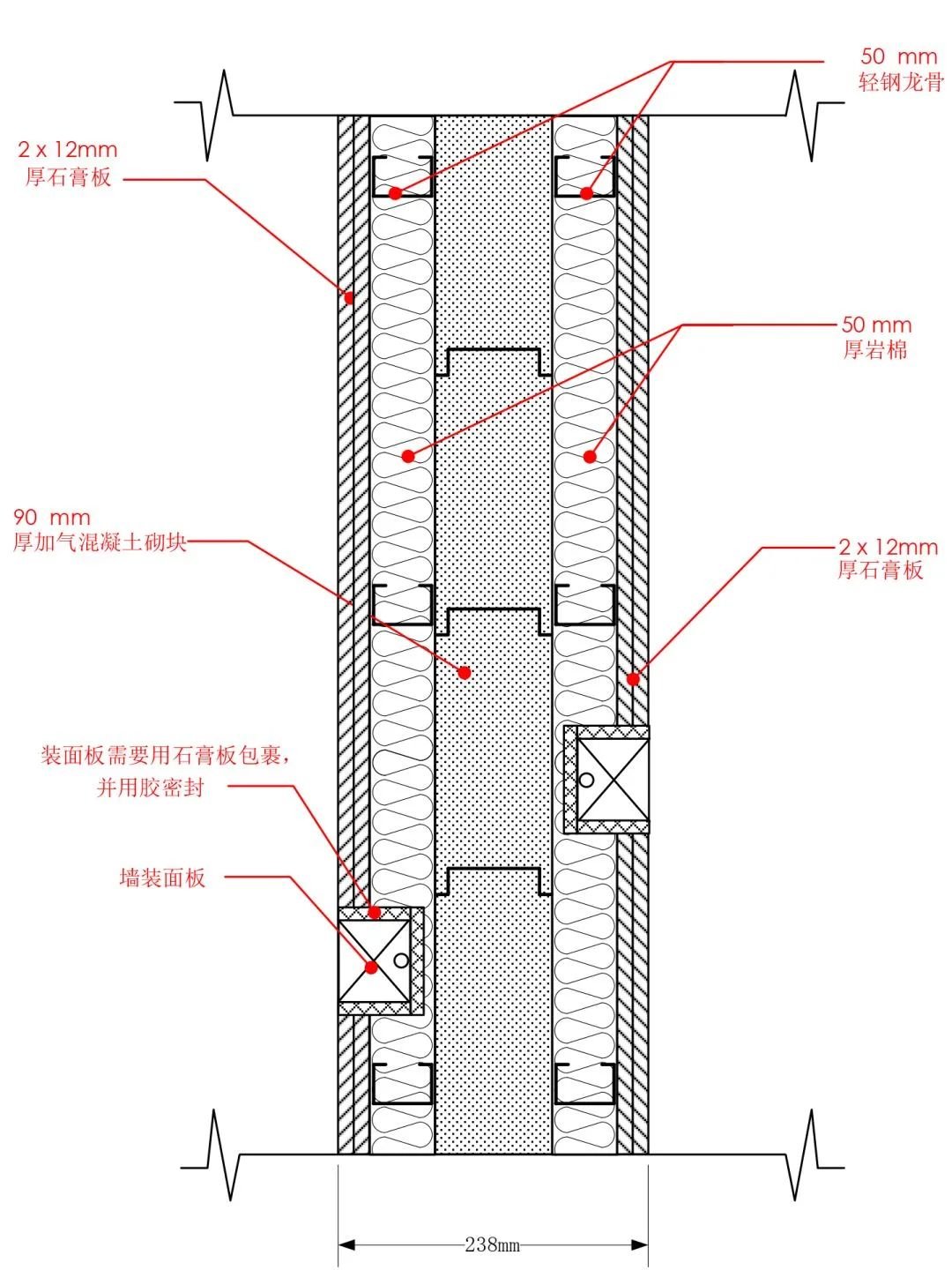

4. STC55 Wall Practice (Masonry and Gypsum Board Composite Wall):

Finished surface:2 x 12mm thick gypsum board, 50mm thick keel (inner-filled rock wool), 90mm thick aerated concrete block, 50mm thick keel (inner-filled kernel), 2 x 12mm thick gypsum board 238mm

Note:

(1) the contents of the rock wool capacity are not less than 80kg, the density of gypsum board is not less than 12kg, and the density of concrete blocks is not less than 600kg

(2) Gypsum board needs to be mis-stitched installation, all boards and plates, the ground and the ceiling between the contact should be sealed with soft sealant edge;

(3) Wall panel box side and back need to be sealed with gypsum board ceiling, avoid the terminal box back-to-back installation, at least 600mmbetween the terminal boxes.

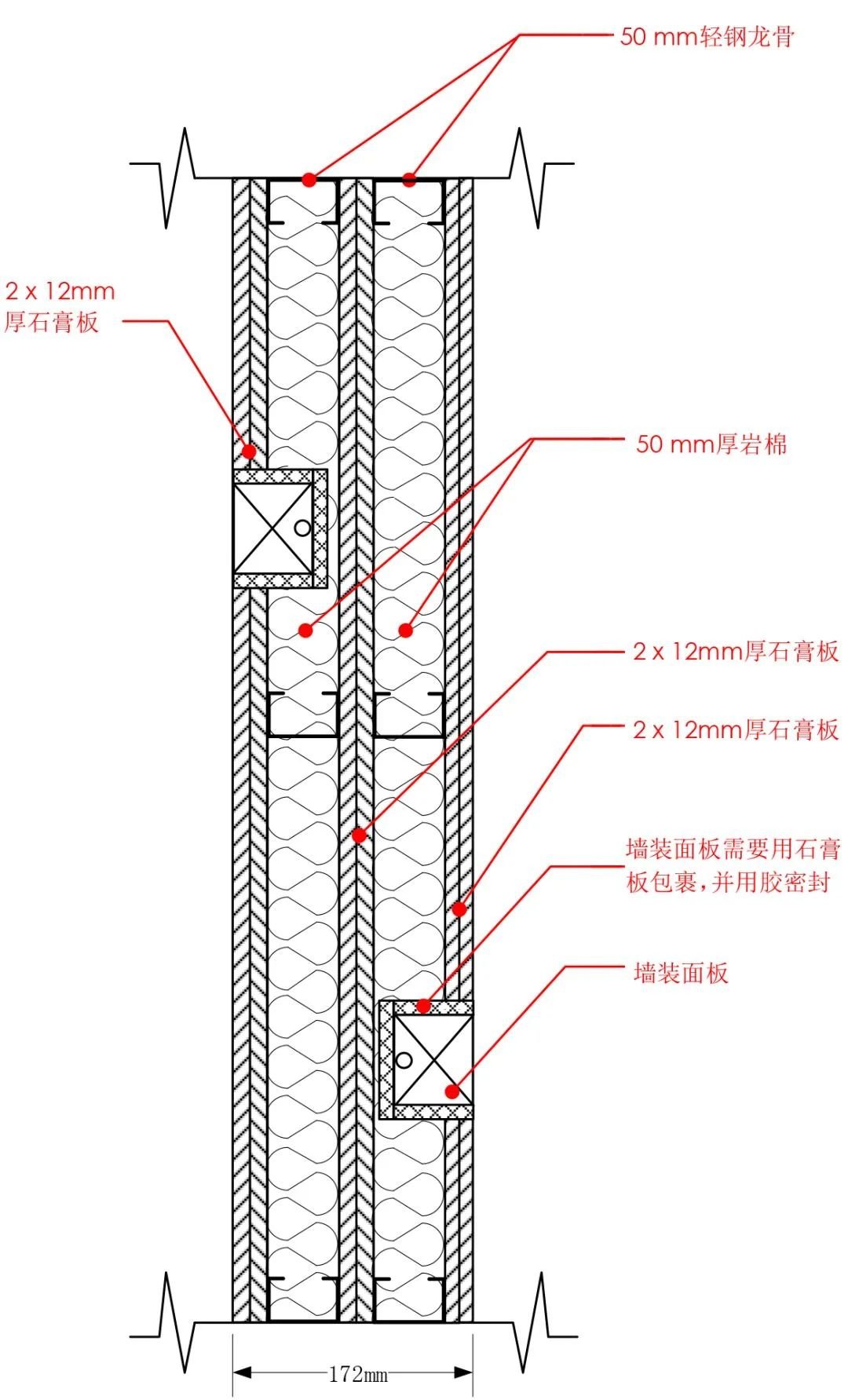

5.STC55 Wall Practice (Lightweight Wall):

Finished surface:2 x 12mm thick gypsum board, 50mm light steel keel (inner rock wool), 2 x 12mm thick gypsum board, 50mm light steel keel (inner rock cotton). 2 x 12mm thick gypsum board s 172mm

Note:

(1) the contents of the rock wool weight are not less than 80kg, the density of gypsum board is not less than 12kg;

(2) Gypsum board needs to be mis-stitched installation, all boards and plates, the ground and the ceiling between the contact should be sealed with soft sealant edge;

(3) Wall panel box side and back need to be sealed with gypsum board ceiling, avoid the terminal box back-to-back installation, at least 600mmbetween the terminal boxes.

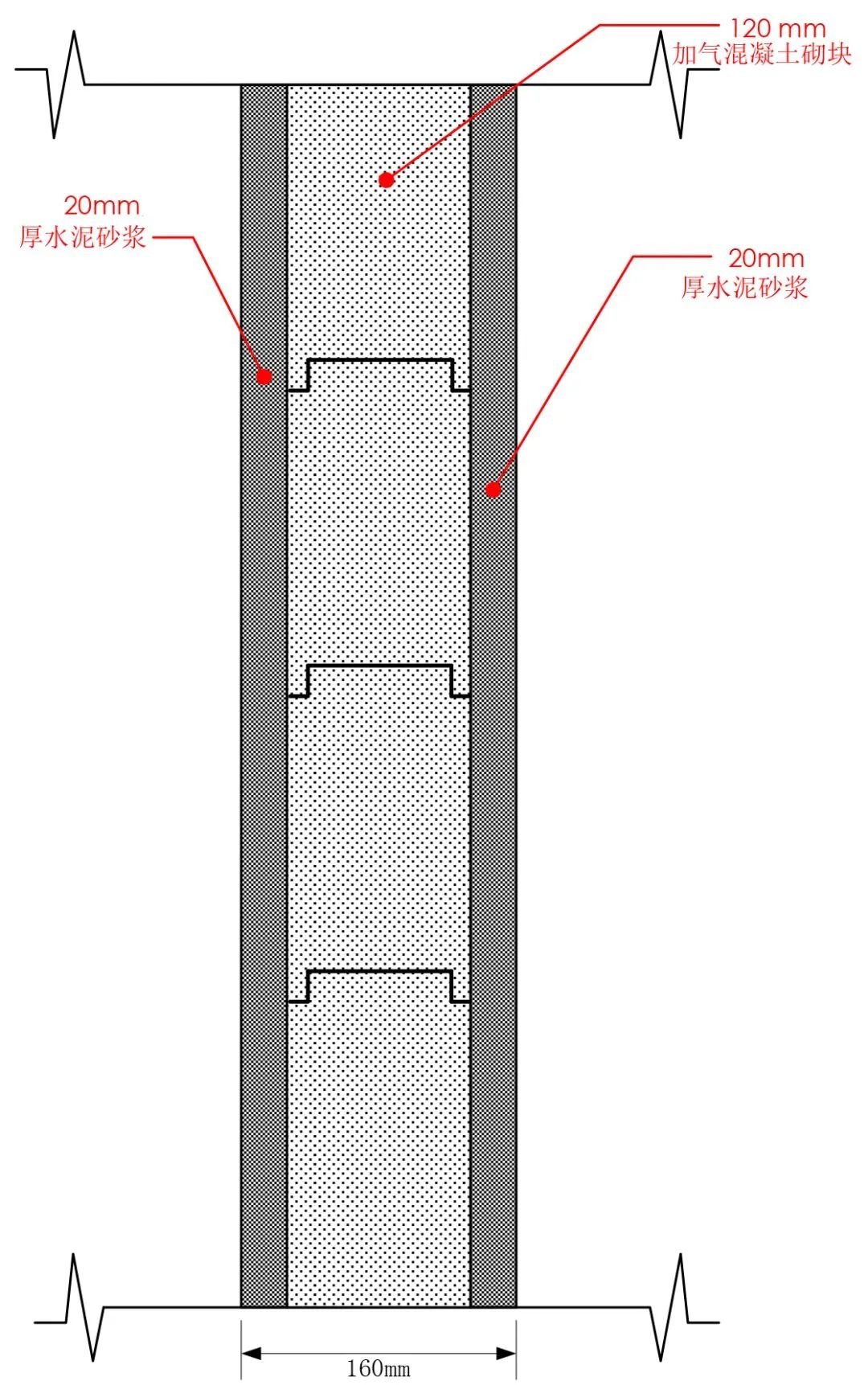

6.STC50 Wall Practice (Block Wall):

Finished surface:20mm thick cement mortar plaster smoldering morning smores

Note:

(1) block density is not less than 600kg, cement mortar density is not less than 2000kg

(2) Wall practice should be through the top, can not only achieve the height of smallpox;

(3)The pipe is filled with rock wool through the wall and sealed with cement mortar.

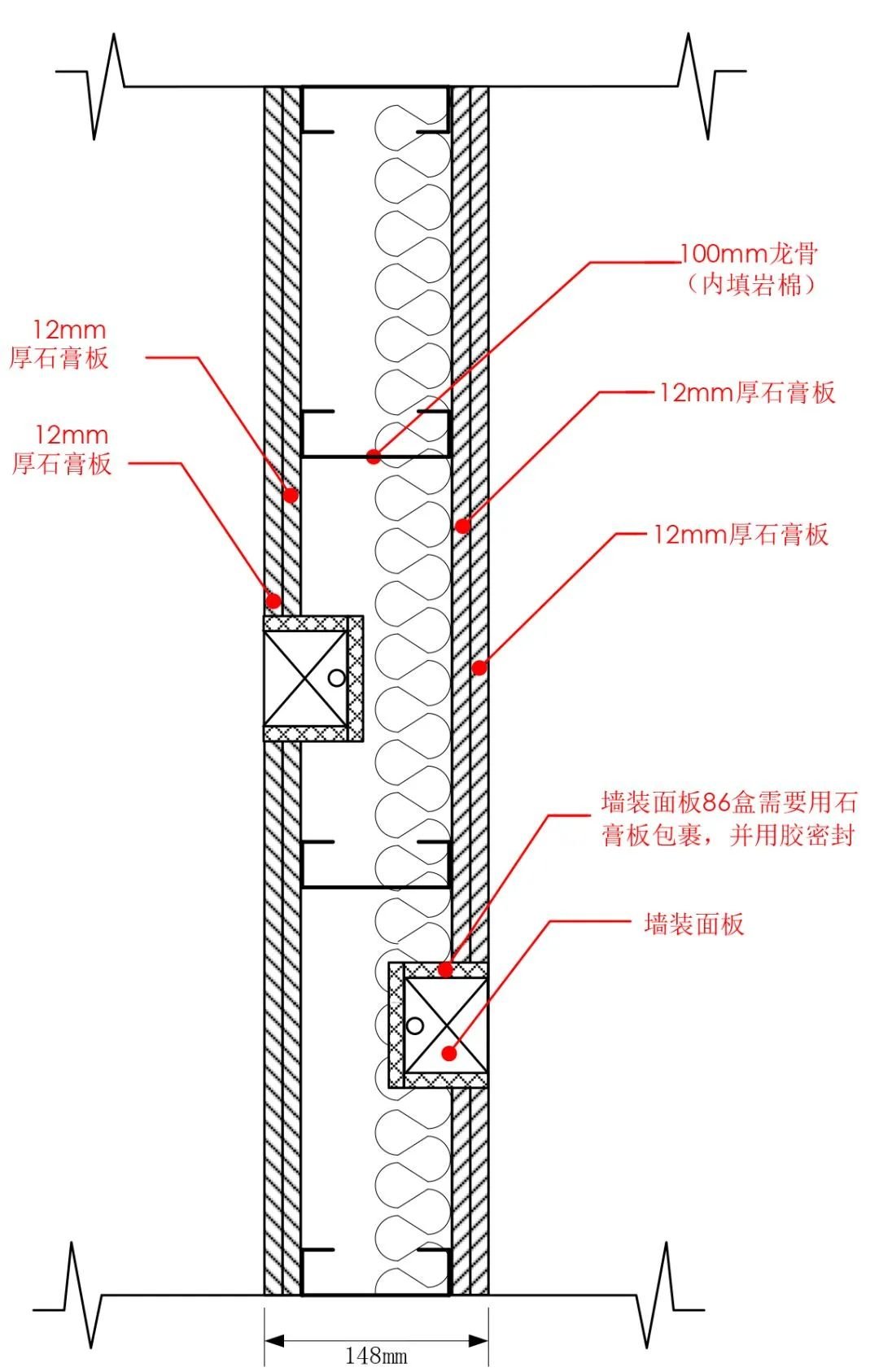

7.STC50 Wall Practice (Lightweight Wall):

Finished surface:2 x 12mm thick gypsum board, 100mm light steel keel (inlaid with rock wool), 2 x 12mm thick gypsum board, 148mm

Note:

(1) the contents of the rock wool weight are not less than 80kg, the density of gypsum board is not less than 12kg;

(2) Gypsum board needs to be mis-stitched installation, all boards and plates, the ground and the ceiling between the contact should be sealed with soft sealant edge;

(3) Wall panel box side and back need to be sealed with gypsum board ceiling, avoid back-to-back installation of the terminal box, at least 600mmbetween the terminal boxes.

03

Active partition walls, doors and windows, floors, and device soundproofing control

1. Active partition soundproofing requirements:

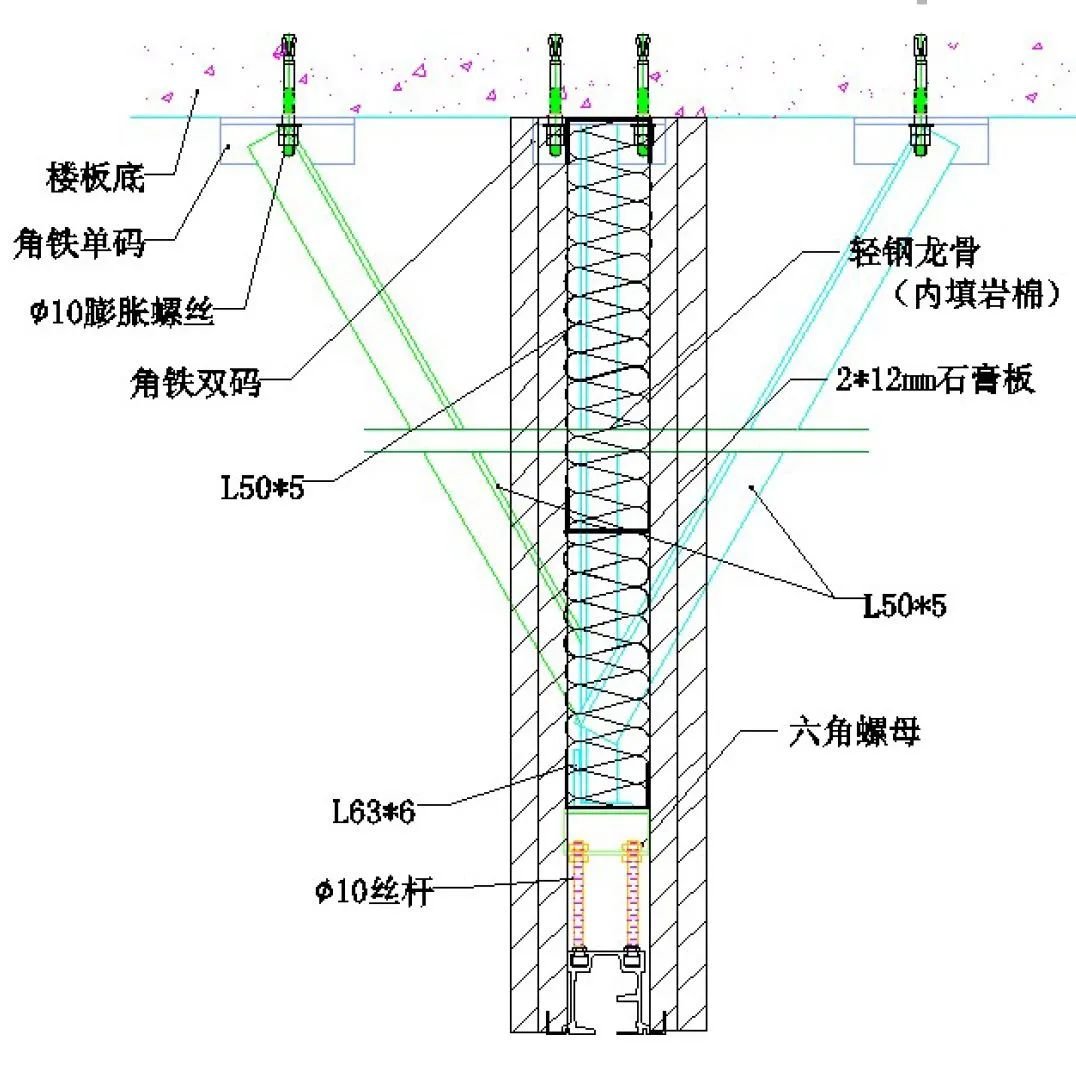

For the active soundproof wall product, it must have an active pressure seal at the top, bottom, and sides, as follows are the acoustic requirements of the active partition wall:

(1) Conference room and banquet hall event soundproof wall The distance from the upper side of the elevator rail to the structural ceiling must be soundproofed.

Treatment:2 x 12mm gypsum board and light steel keel (filled with rock wool)s2 x 12mm gypsum board. The keel size depends on the width of the steel frame track, and the position through which the duct passes must be sealed to prevent sound from passing through the top of the soundproof wall. (See the big picture below for details).

2) The amount of sound insulation on the active soundproof wall needs to be on STC53(decibels).

3) Banquet hall and conference room ceiling should be double-layered gypsum board, filled with the sound-absorbing cotton ceiling.

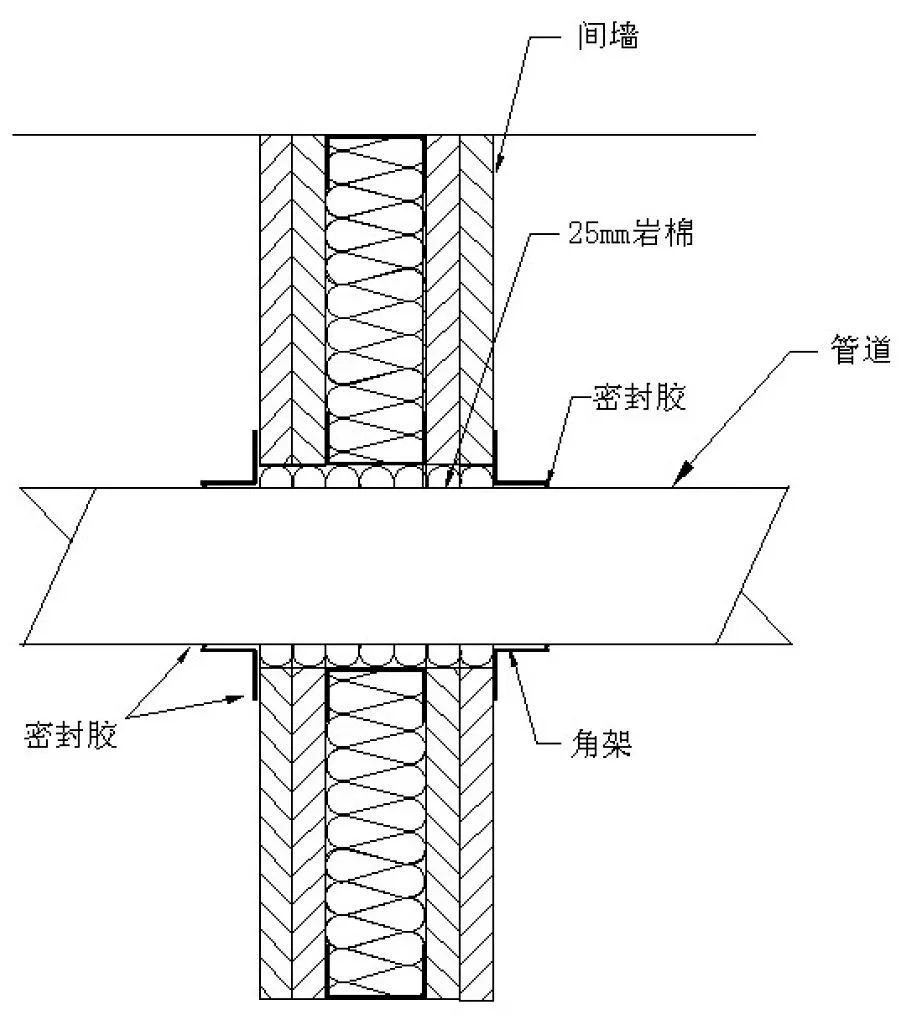

4) For the wall of the pipe above the ceiling of the meeting room and banquet hall through the activity partition wall, we recommend sealing the pipe with rock wool and sealant with the gap around the wall.

As shown in the figure:

2. Door soundproofing requirements:

Currently used in conference rooms, banquet halls, and guest rooms, the door, basically are wooden double doors, sound insulation is often the weakest link.

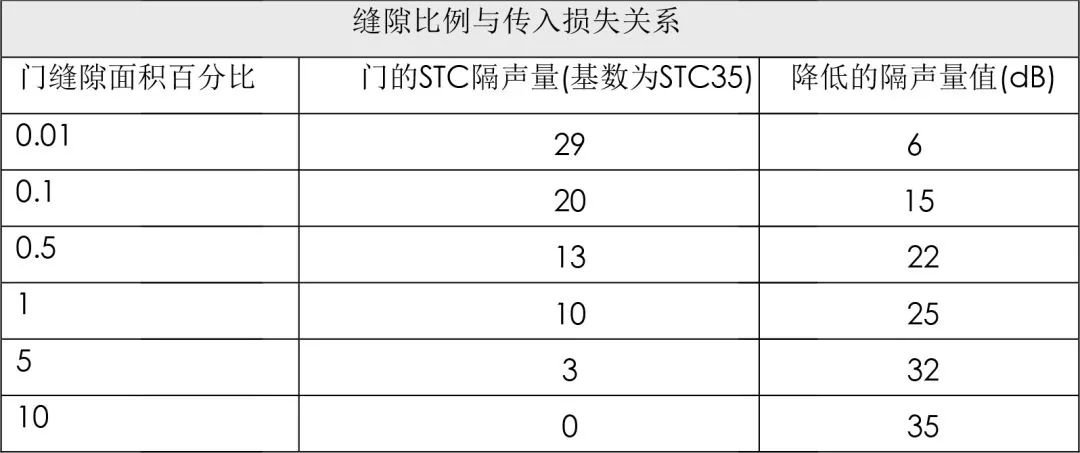

Because the surface density of the door is small, belongs to the thin enclosure components, the general sound insulation is between STC30-35 (decibel) so that the door gap processing must be in place because the gap around the door is an important way to transmit sound, which is the main reason for the door sound gap.

The wall of the door occupies a smaller area than the wall, its low-frequency resonance also often occurs in the sensitive area of sound frequency, so the key to improve the sound insulation of the door is the material of the door itself and the seal of the surrounding gap, the following table shows the door gap affects the corresponding relationship of the sound insulation of the door itself:

The table above reflects that air gaps have a great impact on the sound insulation effect of the door, so we make the following three recommendations:

1) The door itself the amount of sound insulation should be above STC35(decibels).

2) The door needs to be designed with a ladder to seal the door gap, the door frame ladder entrance needs to be installed with soundproofing to seal the gap.

3) If there is no door frame ladder, the door seal needs to be filled with compressible material, the filling material can be rubber or felt, coupled with a sealing pressure strip, so that the door sound insulation achieves its sound insulation standard.

3. Curtain wall soundproofing requirements:

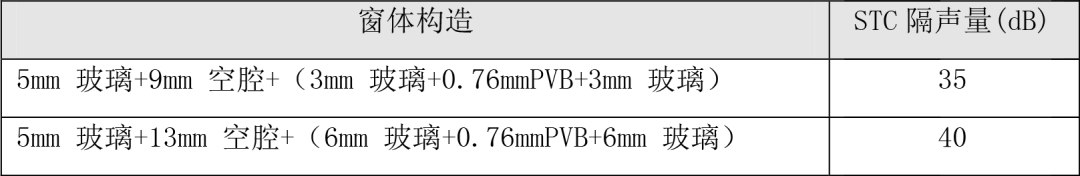

The curtain wall because it is connected to the outdoor, is the weak link of sound insulation. We give two hollow clamp curtain wall practices for the owner’s reference:

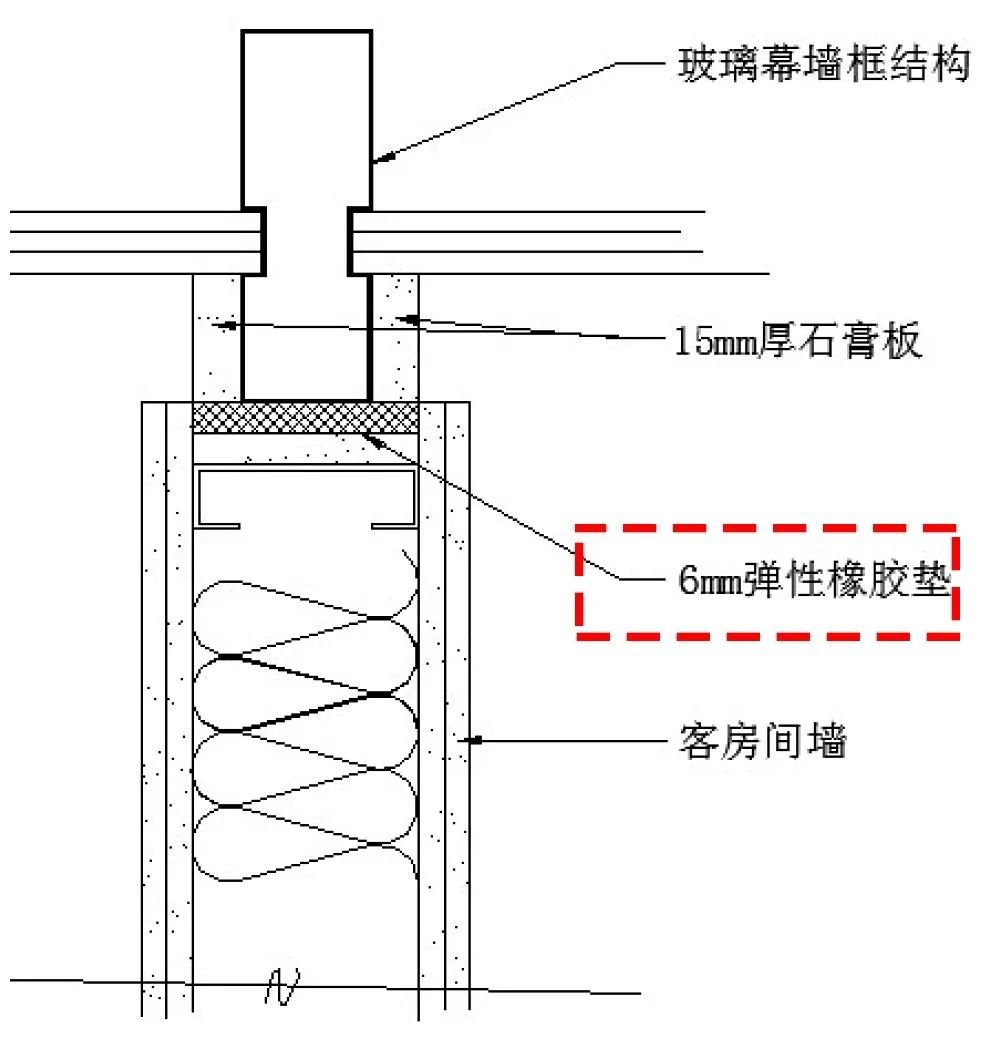

Curtain wall and floor vertical gap blocking as far as possible to fill the way of rock wool, for the curtain wall and room wall horizontal junction part, is easy to leak the link, need to do a strict job of sealing, see the following practice diagram:

4. Ground sound insulation requirements:

Floor impact sound mainly comes from the upper area of the meeting room, we recommend the upper area of the ground carpet, carpet can achieve good impact elimination.

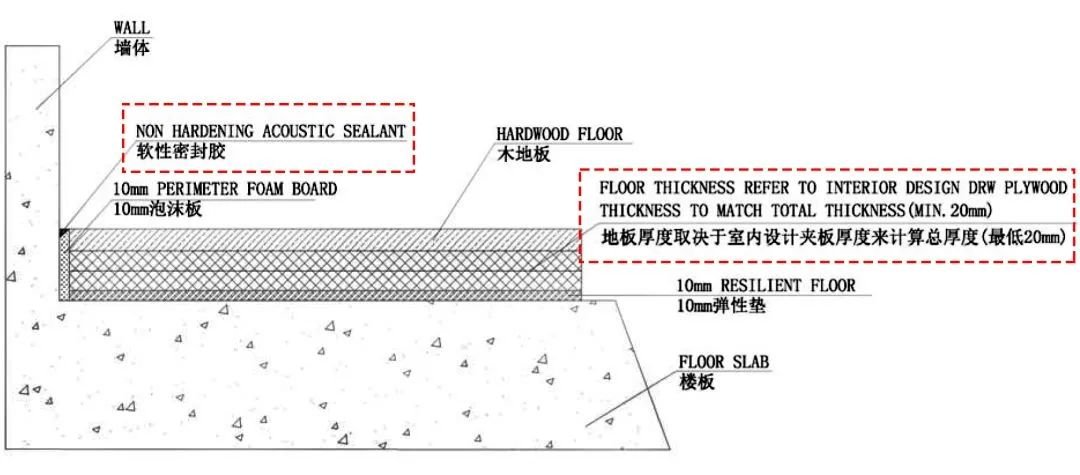

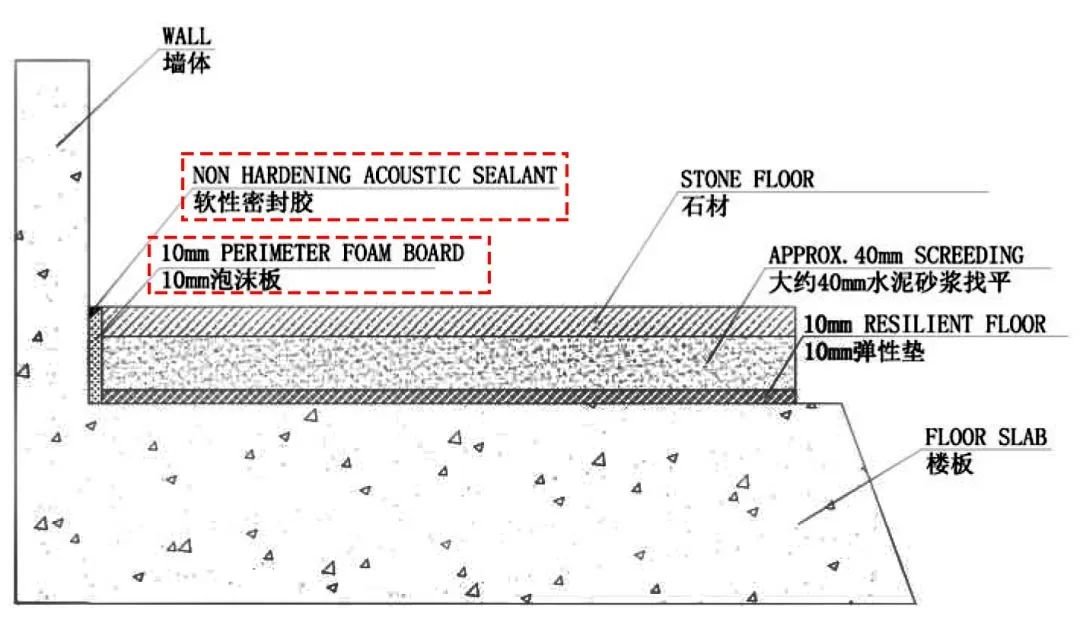

If there is no carpet, the need to do the vibration base under the corresponding ground decoration, the most commonly used ground decoration is stone floor tiles and wooden floors.

The structure of the upholstery recommended for installation under the wooden floor is as follows:

The structure of the upholstery recommended for installation under the floor tiles is as follows:

5. Toilet flushing noise requirements:

At present, the water pipe material is divided into cast iron, mute and PVC pipe, the specific noise reduction method is as follows:

1) Cast iron pipe is thick, no silence treatment is required.

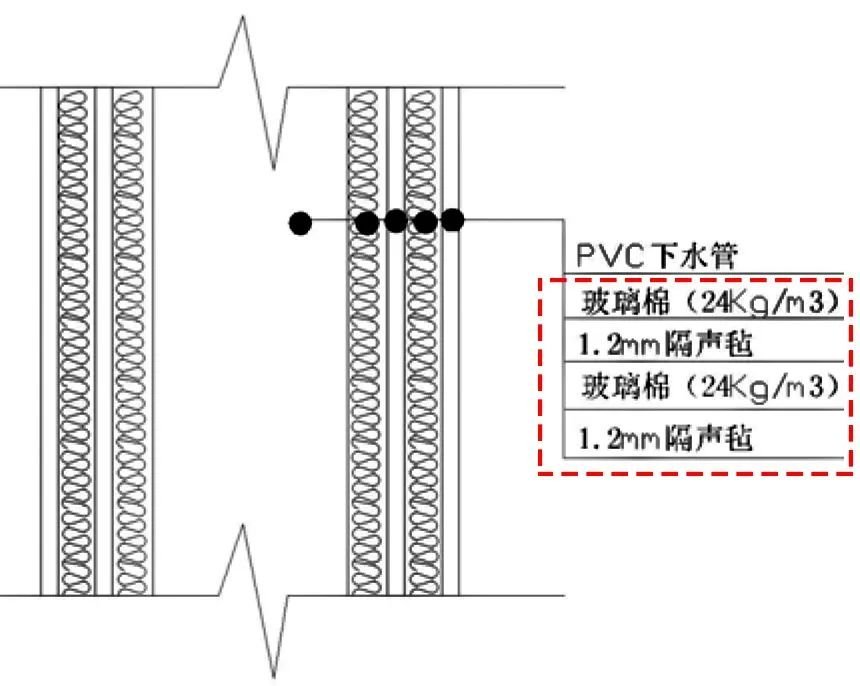

2) PVC tube can be effectively solved by pipe bandage, usually can get 8 to 10dB noise reduction effect;

3) If the conditions do not allow the choice of silent drains, you can improve the noise reduction effect of about 4dB.

6. Pipe vibration:

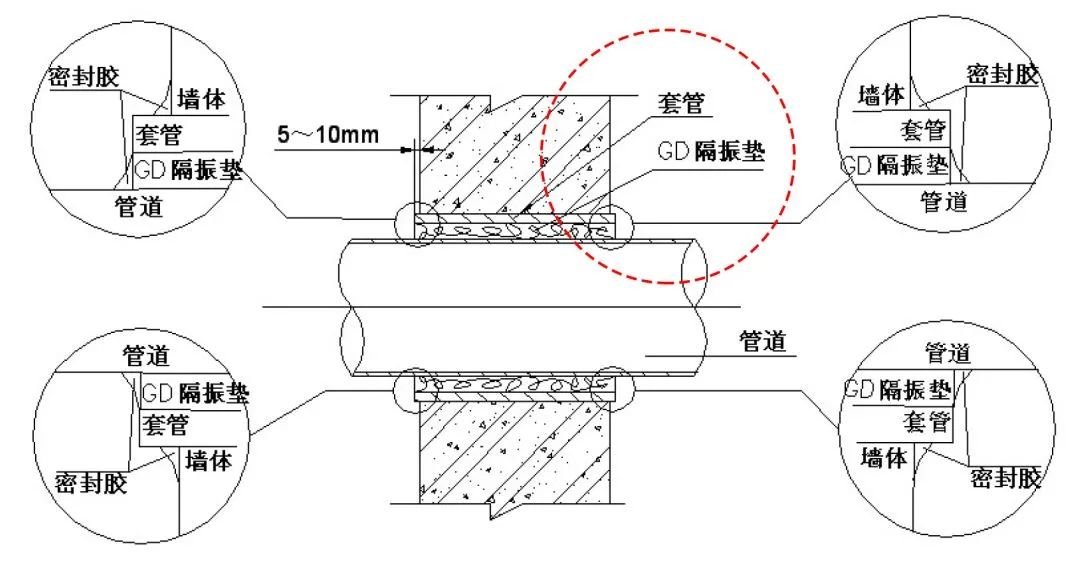

(1) For pipes crossing the wall, it is recommended to seal the gap between the pipe and the wall with casings and vibration cushions, and then seal with sealant, as shown below

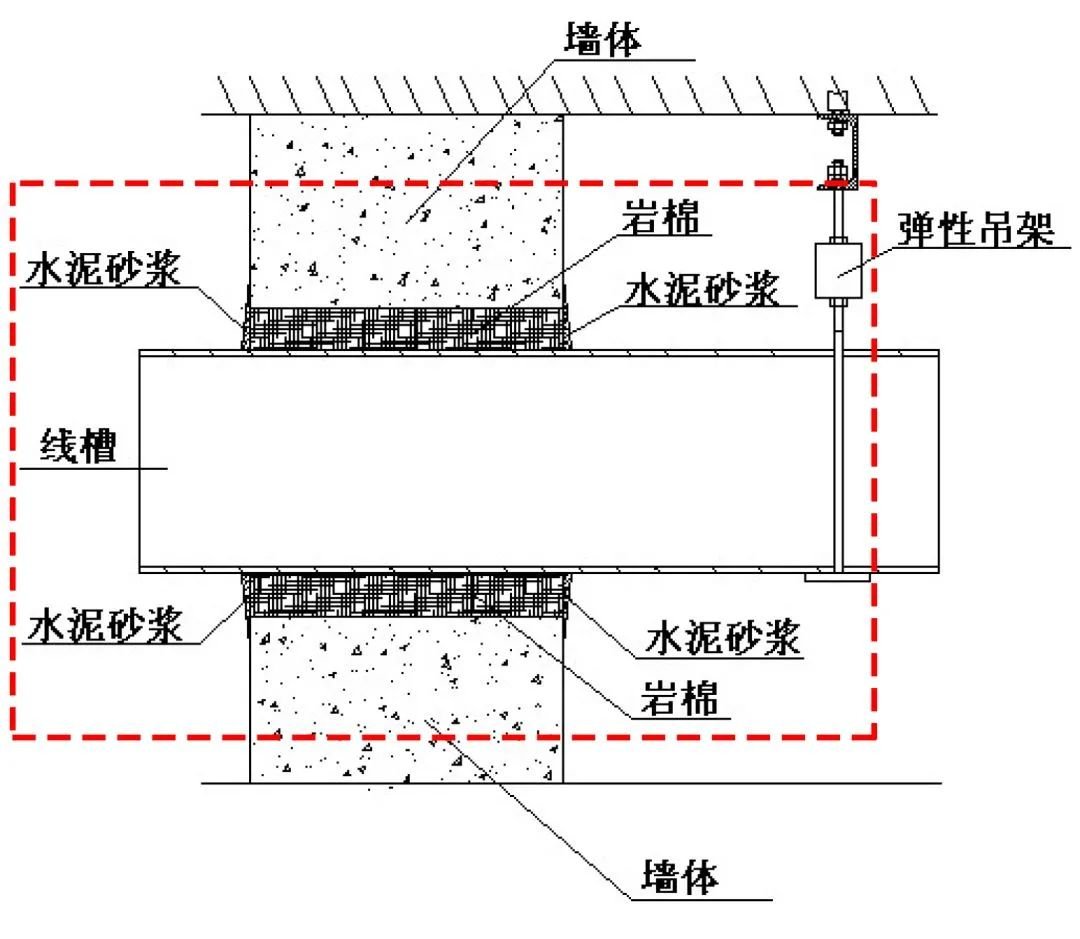

(2) For the line groove through the wall, it is recommended to use rock wool to seal the gap with the wall, and then seal with cement mortar, the line groove needs to be lifted with an elastic hanger to avoid vibration transmission, the big picture is as follows:

Your knowledge card