1, ceiling plate surface no cracks, repair marks are not obvious, indicating flat.

2, ceiling arrangement beautiful, lamps, smoke, spray, air vents, and other end equipment center symmetry, line up.

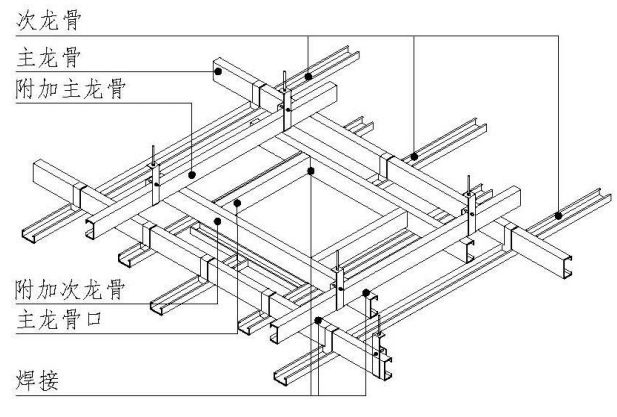

3, control metal boom, keel, steel buried parts, and type steel pendants, should be treated with rust.

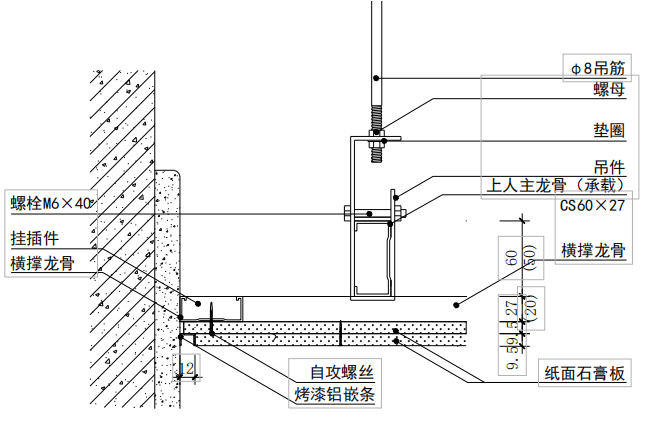

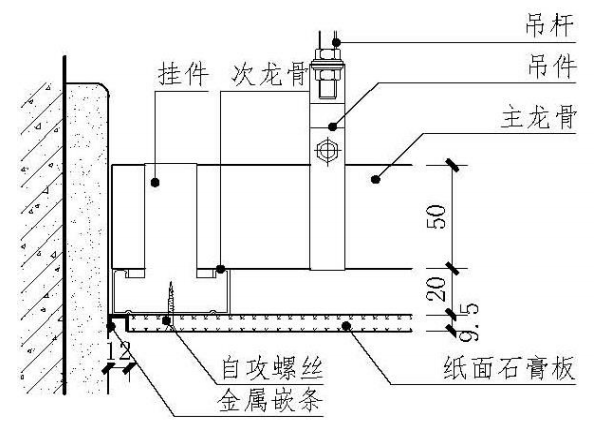

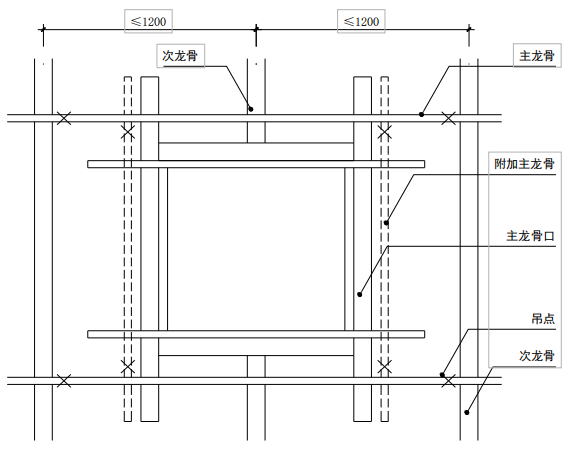

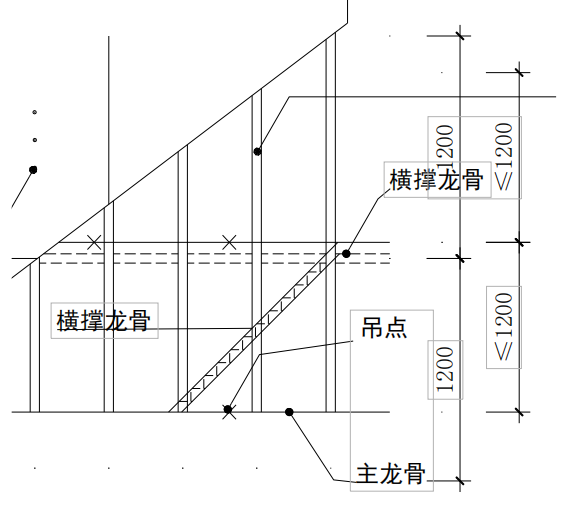

4, dark keel ceiling engineering boom, keel, and finish material installation must be secure, the boom should be vertical, force balance.

5, the main keel should be suspended on the boom, the suspension rod from the end of the main keel distance should not exceed 300mm, when greater than 300mm, should increase the boom.

6, paper gypsum board ceiling corner strengthening, should use the whole plate cut.

21

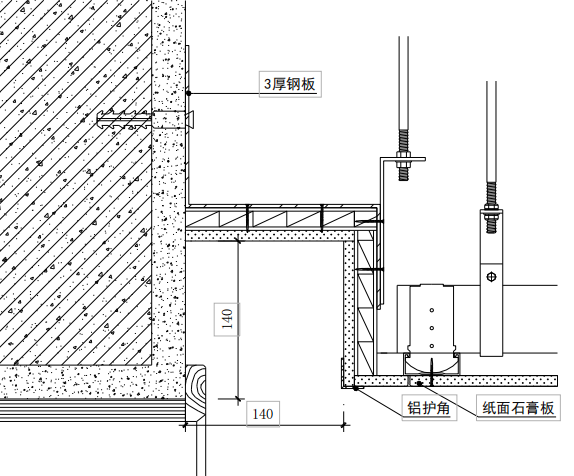

The overall surface ceiling — the top of the wall is handed over

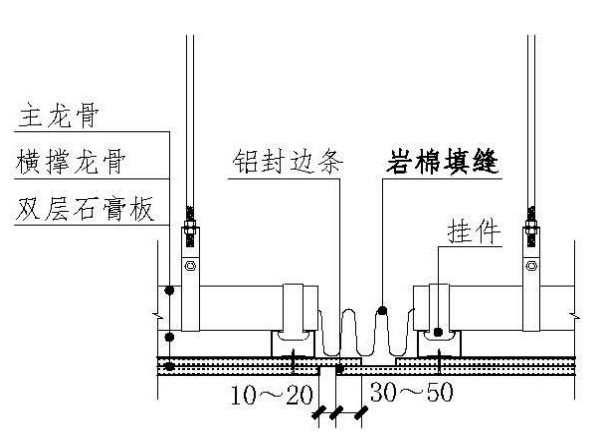

1, pre-controlled wall top junction ceiling elevation.

2, the wall top junction at the second layer plate reserved 10to12mm grooves, internal sticky finished inserts, grooves should be straight, wide, and narrow consistent.

3, near the junction of the top of the wall 20cm strictly controls the flatness of the wall.

1, ceiling and wall junction, leaving 20mm wide,15mm deep groove.

2, grooves should be straight, wide, and narrow consistent, allowing deviation of ≤1mm(check with a steel ruler).

22

The overall surface ceiling — telescopic seams

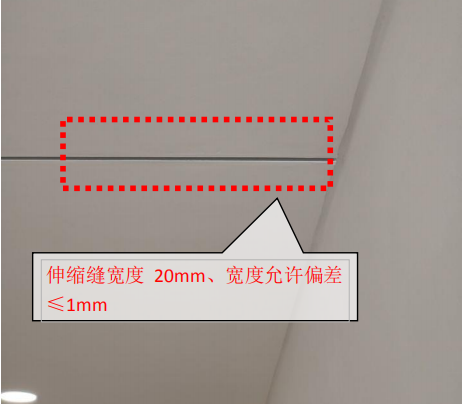

1. When the gypsum board ceiling length reaches 12m(inclusive) or when the structure of the building is encountered, the telescopic seam must be set.

2, telescopic seam width 20mm, width allowed deviation of ≤1mm.

3, telescopic seam main keel, finish layer should be disconnected.

23

The overall surface ceiling — the access port

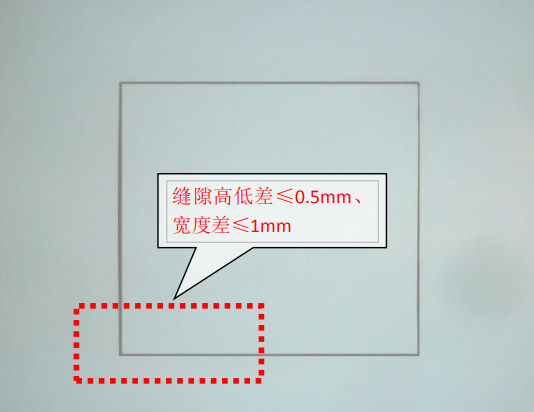

1, the material and color of the access port should be consistent with the ceiling panel to ensure the overall decorative effect.

2, can be mined metal finished repair port, can also use gypsum board paperback access port, design no requirements, should use 500mm x 500mm access.

3, the gap around the access port is tight, the difference between high and low ≤ 0.5mm, width difference ≤ 1mm.

1, the material and color of the access port should be consistent with the ceiling panel to ensure the overall decorative effect.

2, the upper ceiling access point needs to attach the main keel.

3, gypsum board paperback access port border and cover installation finished seal edge strip.

24

The overall surface layer ceiling — air vent

1, the air vent position should be fixed separately, not fixed on the keel.

2, the hole in the ceiling should not be too large, and close to the ceiling, installation is strong.

25

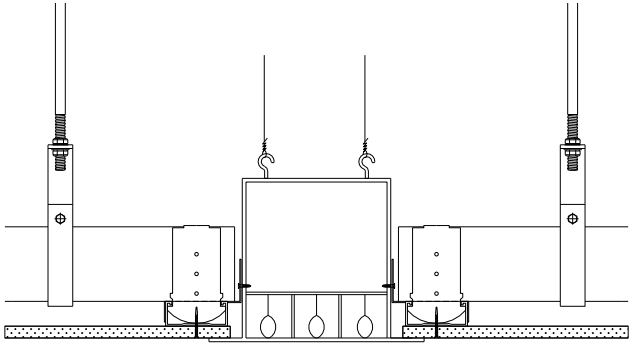

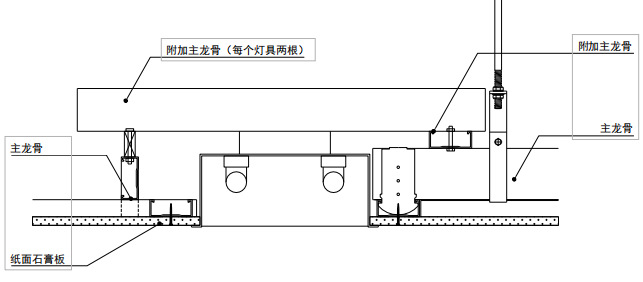

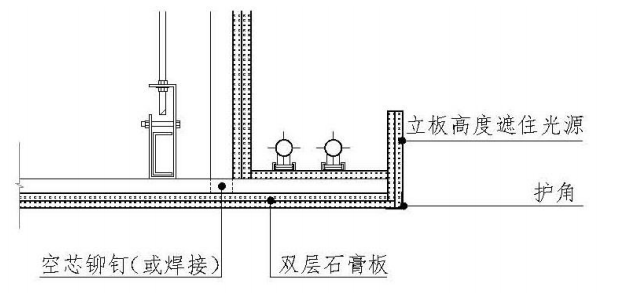

Integral surface ceiling – lamp installation

1, ordinary lamp installation needs to attach the main keel fixed, lamps on the ceiling should not be too large, and the ceiling closely installed firmly.

2, more than 3 kg of lamps, fans, and other heavy equipment is strictly prohibited to install on the keel of the ceiling, should be separated hanging pendants and structural connection.

3, more than 10 kg of lamps, its pendants should be firmly connected to the structure, and do 5 times the lamp weight overload test.

26

The overall surface layer ceiling — the corner is strengthened

To reduce cracking in the direction of the 45-degree angle of the gypsum board ceiling, a 45-degree oblique light steel sub-keel can be added at the corner.

27

The overall surface ceiling — the curtain box

1, curtain box and ceiling relationship, divided into clear and dark. The line of the ceiling and curtain box handover area should be straight, the curtain box should be square in the yin angle, evenly coated.

2, curtain box junction wall should be fixed with the wall, strictly prohibited only one-sided boom hanging form fixed.

28

The ceiling of the whole surface layer — Yin and Yang angle

1, ceiling yin and yang angle square positive ≤ 2mm.

2, clear line angle, clear lines, clean and beautiful.

29

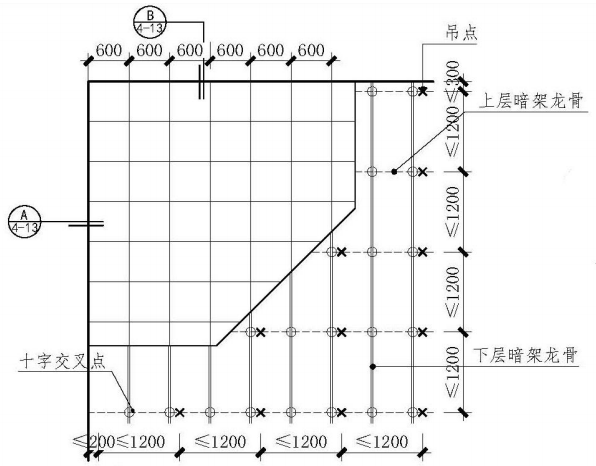

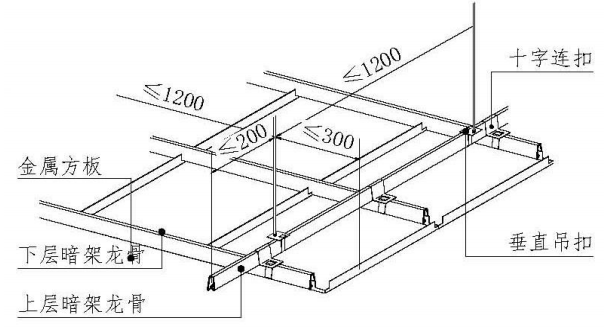

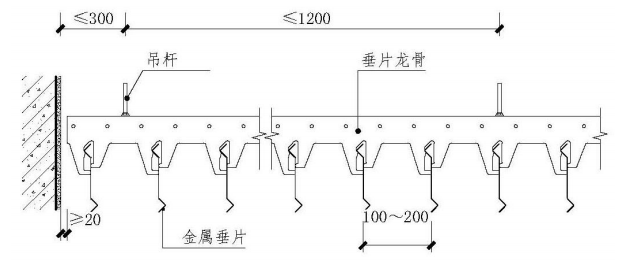

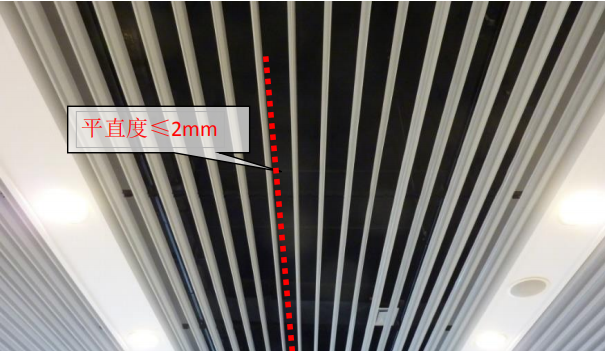

Section surface ceiling — metal plate ceiling

1, plate installation clean, flat, surface flatness ≤ 1.5mm.

2, lamps, smoke, spray, and other equipment are located in the center of the plate.

1, plate grid straightness ≤1mm(pull 5m line, less than 5m pull line, check with steel ruler).

2, the gap between the plate is uniform and consistent, in line.

1, metal plate ceiling should be sewn straight, with no wrong platform, width, and narrow consistency.

2, during the installation process, to prevent metal plate deformation and other reasons caused by the phenomenon of excessive gaps.

3, in advance to determine the access port position, such as the use of flaps instead of the access port, the need to strengthen the keel structure at this board

30

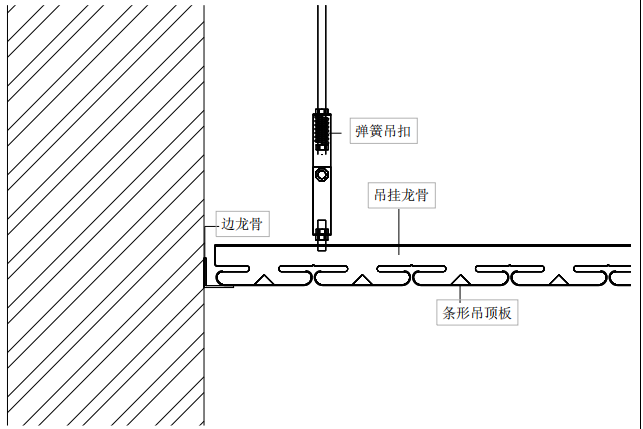

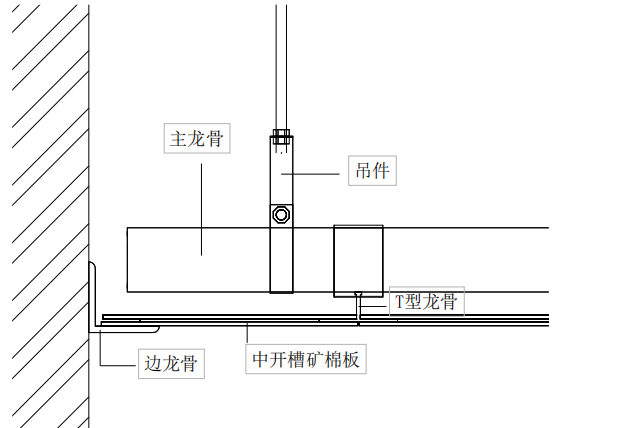

Plate surface ceiling — mineral cotton plate ceiling

1, symmetrical arrangement: plate ceiling horizontal should choose the “odd” plate, symmetrical installation.

2, line up: lamps, smoke, spray head, air vents, and other equipment end unified centralized layout installed in the center of the plate, lamp center. 3, installation of the keel as required to level or arch, so that the top surface is flat.

4, large-size mineral cotton plate installation needs to consider strengthening measures to avoid the plate surface due to self-weight bending deformation.

31

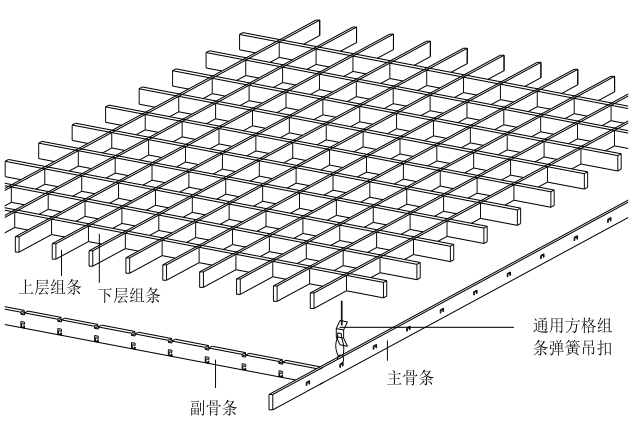

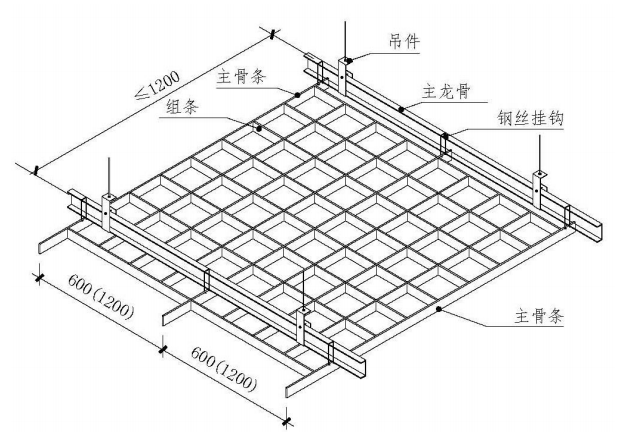

Grille ceiling

1, grille, square pass, hanging plate, and other through the structure of the ceiling, mechanical and electrical pipeline should be sprayed according to the design requirements, mechanical and electrical pipeline according to the standard construction of the open pipeline.

2, metal square through the ceiling should be used special keel, pendant installation. The aluminum square of the mounting angle needs to be adjusted and can be mounted with a special pendant.

3, grille ceiling should be straight, vertical line, wide and narrow consistent, ceiling lamps should be planned organized arrangement.

4, plate installation clean, flat, surface flatness ≤ 1.5mm.

5, lamps, smoke, spray, and other equipment are located in the center of the plate.

Grille installation is neat, flat, surface flatness ≤ 1.5mm, high and low difference ≤ 0.5mm.

Bar grille spacing is consistent, lines clear, straight, straight ≤ 2mm.

– Ground installation works –

32

Water mill stone ground

1, solid stone, uniform, consistent color pattern, not mixed color, particle size in addition to special requirements should be 6mmto16mm.

2, the current surface layer of water millstone used stone particles should comply with the provisions and design requirements should be combined with the lower layer firmly, should not have empty drums, cracks.

3, the surface should be flat, smooth, there should be no obvious cracks, sand eyes, and grinding marks. Stone grain should be dense, uniform, consistent color, gloss qualified, a color pattern consistent, non-mixed color, the grid should be straight, clear.

33

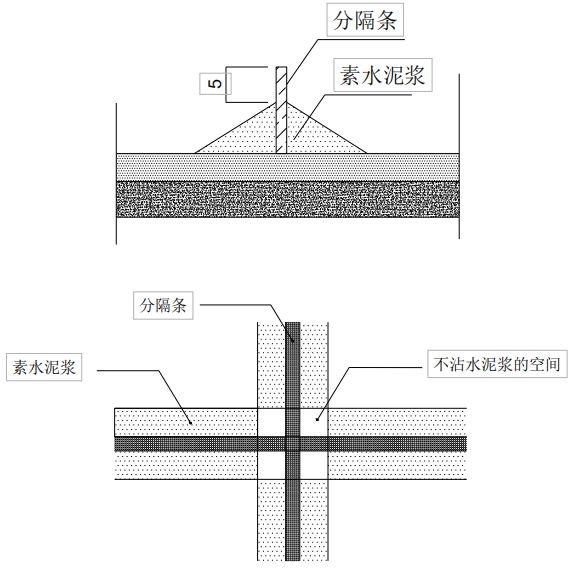

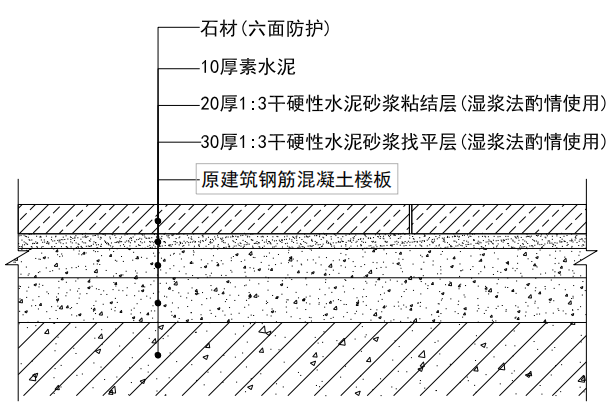

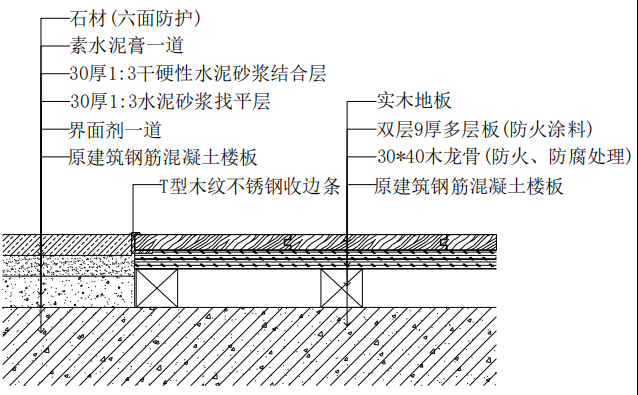

Marble or granite floor

1, the ground stone should be 6 sides brush protective agent, brushing the number of times must not be less than 2 times.

2, no obvious color difference, texture smooth, surface layer generally using tight seam treatment (within1mm), seam straight and tight, sewing full and beautiful.

3, the stone ground is strictly prohibited to take local grinding treatment.

4, stone paving should be maintained for more than seven days, prohibited to move around and carry things.

34

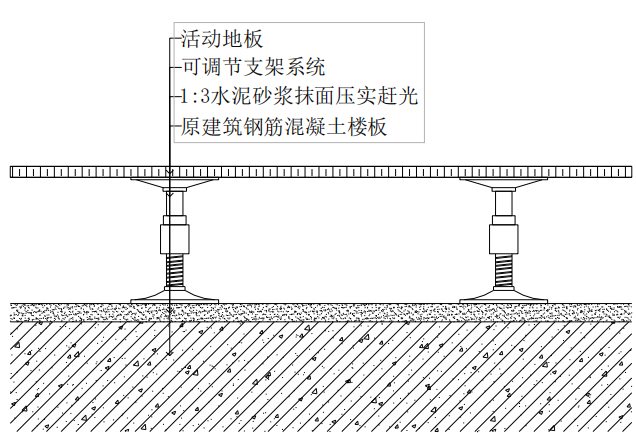

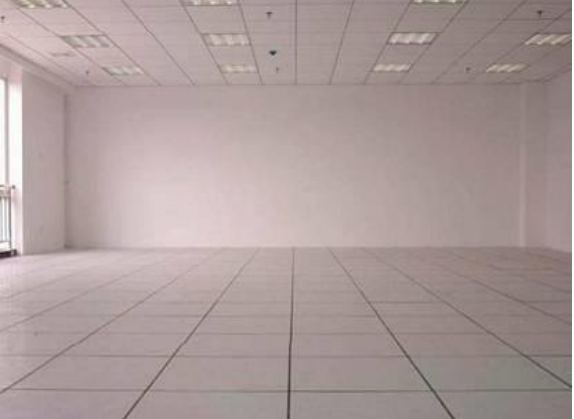

Active floor floor

1, all support posts and beams of the floor shall constitute the overall frame and be securely connected to the base. The height of the bracket should meet the design requirements after flattening.

2, the surrounding side of the application of wear-resistant hard plate closed or wrapped with galvanized steel plate, the edge of the strip should meet the wear-resistant requirements.

3, floor installation should be solid, smooth, walking without sound.

35

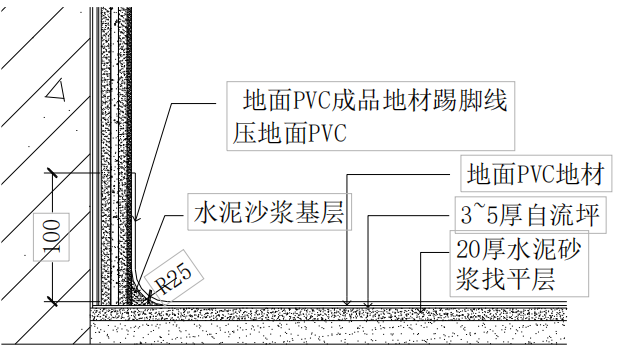

Plastic plate floor

1, the grass should be smooth and hemp-free, flatness is not greater than 2mm, water content is 8%to10%, interface agent should be bepainted uniformly, there must be no exposed bottom and leakage brush, bonding firmly.

2, the ground poured a layer thick 3 to 5mm or so of self-leveling. The wall is connected with a partially filled cement mortar base. And along the cement mortar base paste PVC ground kick.

3, plastic film surface layer should be clean and flat, the pattern at the seams match, no obvious high and low difference, gaps, and glue marks. With the surrounding seams tight, Yin and Yang angle square, neatly closed.

36

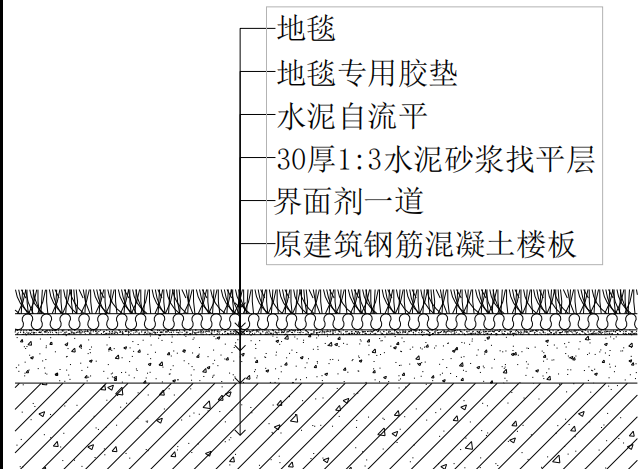

Carpet floor

1, paste method laid carpet, the stitching should not be exposed lining, should be pasted solid, tight flat, carpet clean, pattern matching, should not have drums, wrinkles, cocking edges, curls, dew lines, pollution, and damage.

2, the whole laid carpet should be flat, Zhang pulls suitable, the surrounding and kickline between the seam should be stuffed into the card strip, card bar should be fixed firmly, the door of the application of metal bar fixed.

3, carpet and other surface layer connection, the end and wall, around the column, should be straight, tight.

37

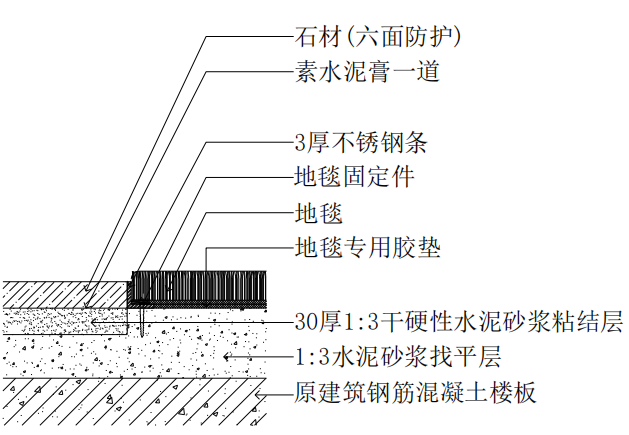

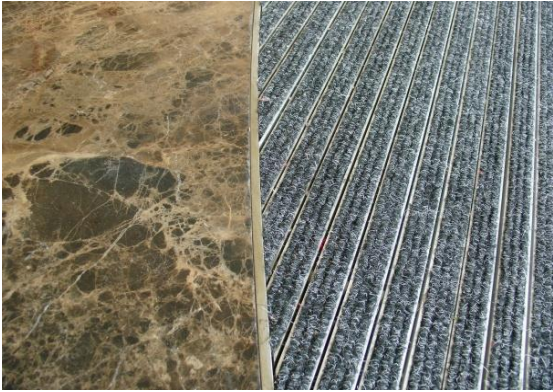

Carpets are handed over to the stone

To make the ground closing at the seams look good, the carpet and marble junction are treated with a 5 to 8mm thick stainless steel edge, which is bonded with adhesive to the stone.

38

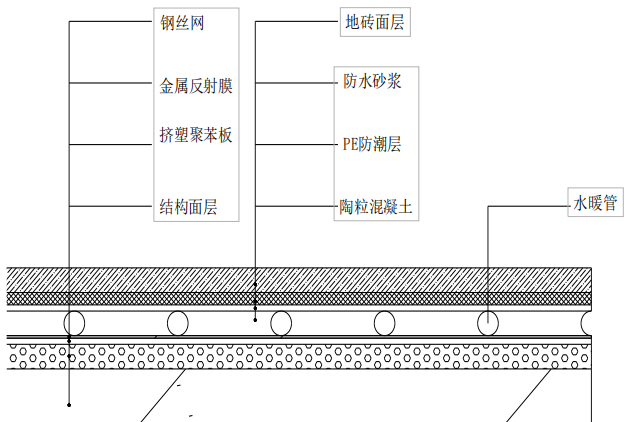

Ground radiation heating plate ground

1, under the ground, laid coil buried part should not have joints.

2, the coil buried before the water pressure test, the test pressure is 1.5 times the operating pressure, and not less than 0.6MPa.

3, heating coil bending part must not appear hard bending phenomenon.

4, the diameter and spacing of the underfloor heating pipe should meet the design requirements, the fixed point spacing of the straight pipe segment should be 0.7-1.0m, and the fixed point spacing of the elbow segment should be 0.2-0.3m.

39

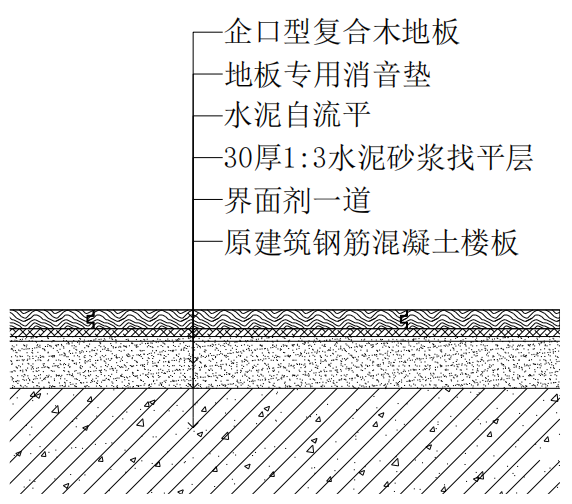

Laminated wooden floors

1, wood flooring grass should be flat, sand-free, not empty cracking, the surface is smooth, clean, oil-free, and do vacuum clean treatment, and water content must not be greater than 8%.

2, bar wood flooring direction should be correct: corridors, aisles should go down the direction of laying, indoor rooms should be laid in the light.

3, the floor surface should be flat, clean, smooth, with no plow marks, no burrs, clear and beautiful pattern, the board should be solid and free of loose.

40

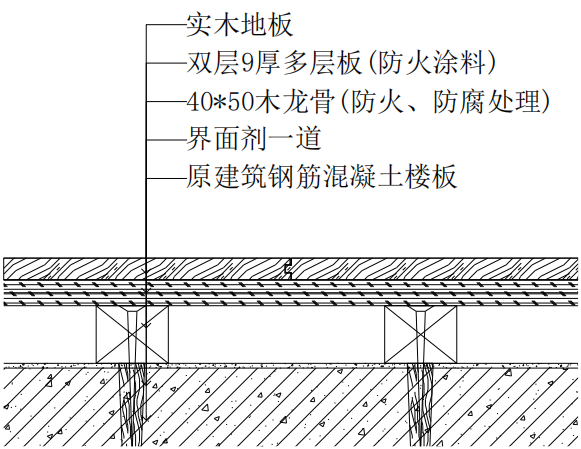

Solid wood floors

1, wood keel needs to use pine wood, the waterproof rate in line with local humidity, and three anti-treatment.

2, under the floor, spread moisture-proof film, interface overlapping with adhesive paste.

3, the adjacent plate joint position should be staggered not less than 300mm distance. There should be a gap of 8mmto12mm between the columns and walls.

41

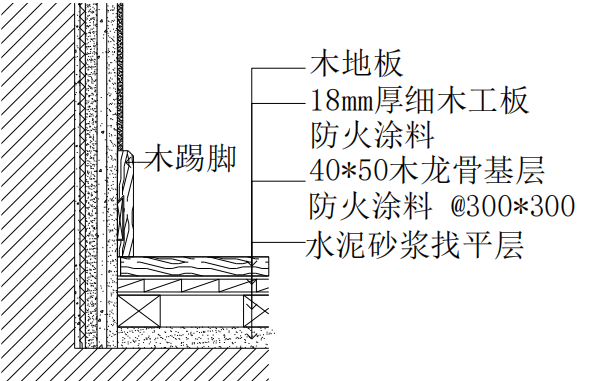

A wooden floor kick line

1, wood floor gap width should be uniform, tight, and columns, walls should be left between 8mmto12mm gap.

2, wooden kick line wooden kickboard in the side against the wall into a groove, and every 1m to retain the diameter of 6mm vents. The wooden kickboard should be cut into 45-degree angles at yin and yang angles.

42

The wooden floor is handed over to the stone

Stainless steel trim strips are screwed to multilayer plates to ensure the flatness of stone floors, wooden floors, and custom stainless steel strips.

– Starworks –

43

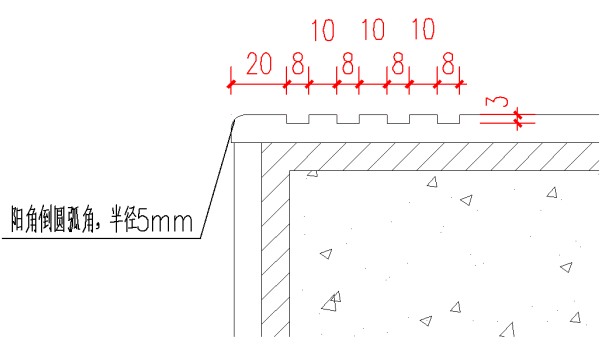

Step on the anti-slip bar

1, finished metal non-slip edge corners should be neat, installation should be straight, strong, durable.

2, stone, tile anti-slip bar should be used planer grinding groove, the anti-slip groove depth is not less than 3mm.

3, anti-slip bar (slot) position should be accurate straight, arranged evenly, and neatly.

44

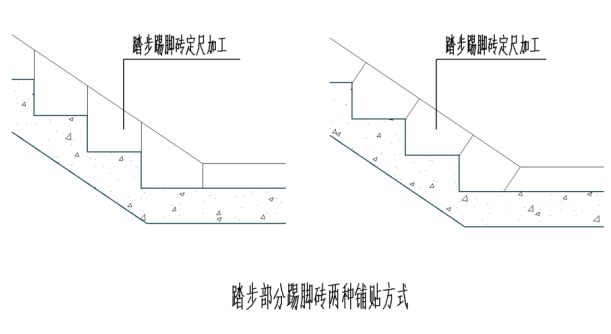

Kick

1, stair-step façade brick and kick brick stitch alignment.

2, kickline thickness out of the wall consistent, the upper mouth.

45

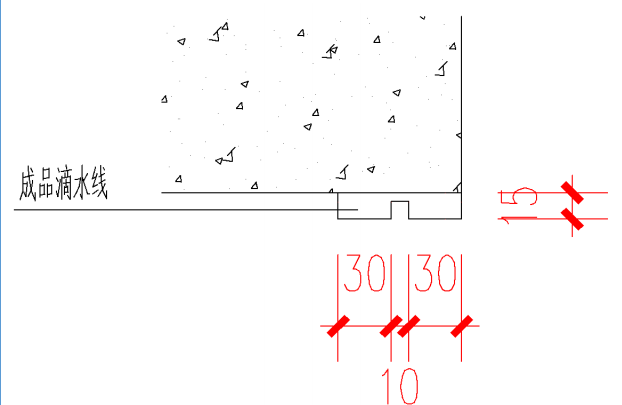

Drop the waterline

1, the lower edge of the stair plate should be set drip line, drip line should be around the circle.

2, dripping line protruding plate bottom is not less than 10mm, width from the façade 30mm, should be square, wide and narrow consistent.

46

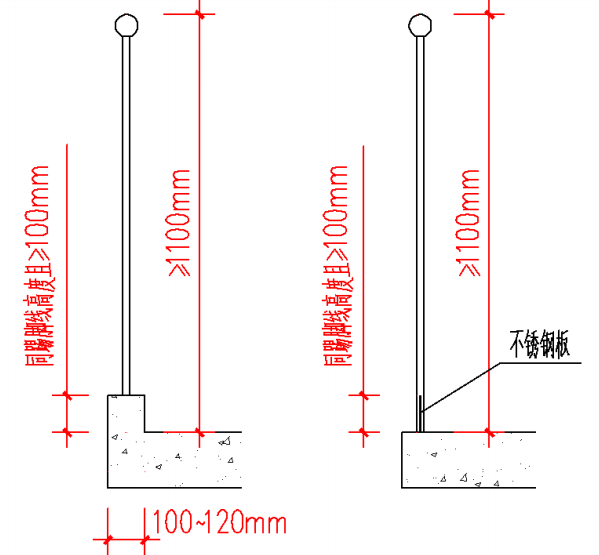

A top platform near-empty railings

The top floor of the stairs should be set up with an anti-falling frame, height is not less than 100mm, the width should be less than 220mm.

47

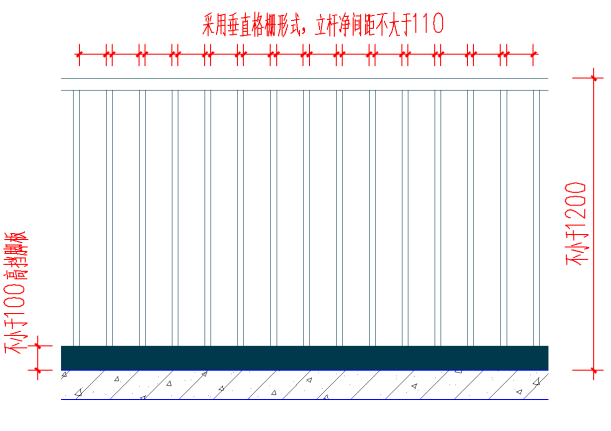

Children’s venue railings

1, residential, nursery, kindergarten, primary and secondary schools, and children-only activities of the railings, stairs must be used to prevent children and young people from climbing the structure.

2, nursery, kindergarten staircase in addition to adult handrails, and should be set up on both sides of the stairs child handrails, its height should be 600mm.

48

Children’s activities are available on the air railings

1, nursery, kindergarten balcony, roof platform, staircase top platform guardrail net height should not be less than 1.20m, the inside should not be supported.

2, the lower part of the platform railing should be set not less than 100mm high bezel.