Latex paint construction process and prevention measures

Construction process (divided into gypsum board grass and original structure grass-root 2 kinds).

(1) Gypsum board grass-root: self-tapping eye brush rust-proof paint → gypsum board seams and self-tapping at the inset sewing gypsum → plate seams with bandages → the bandage outside the again embedded sewing plaster → large area scraping putty twice → Yin and Yang angle bullet line → scrape the third time putty → sandpaper → roll primer → repair, sandpaper → roll first paint → Finely grind → roll the paint a second time

(2) Original structure grass-root: remove the original white → brush interface agent → local whitewash gypsum repair → large area scrape putty twice → Yin and Yang angle bullet line → scrape the third time putty → Sandpaper → Roll Primer → Repair, Sandpaper → Roll First Paint → Fine grinding → Roll Second Paint

Self-tapping eye brush rust-proof paint (self-tapping rust contaminated latex paint surface);

Gypsum board seams and self-tapping threaded seam gypsum to ensure that the gypsum board is flat;

A bandage is attached to the board of the sewing plaster after filling, so as to prevent cracks;

The outside of the bandage is scraped again with sewing gypsum so that the bandage and plasterboard become one;

Large area scrape putty twice, large area scrape putty twice;

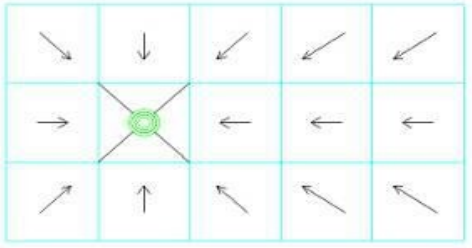

Yin and Yang angle bullet line find side;

scratch the putty a third time;

Sandpaper;

Roll primer;

After sanding and patching roll the first time the paint, then fine grinding, roll the last over the paint;

Construction quality general disease and prevention measures

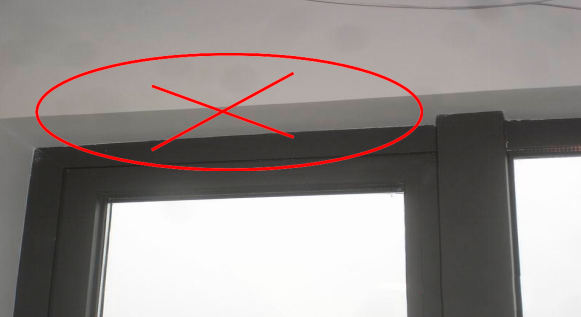

1, around the window frame paint end, is not meticulous, there is the phenomenon of size head.

Strengthen and civil handover acceptance, civil handover acceptance inspection standards: door and window hole height and width (rear plug) ±5(mm)with a ruler inspection, check 10% of the hole, and should not be less than 5 outside the wall of the lower entrance offset 20 ( mm), whichever is the bottom window, check with a latitude meter or a hanging wire to check 10%of the batch and should not be less than 5.

2, latex paint wall wire pipe groove decoration after the cracks.

1) The garbage in the pipe tank must be cleaned up;

2) The groove should be watered and moist before painting, and rinse clean;

3) The outer surface of the pre-buried pipeline should be more than 15mm deep with the originally painted surface layer ( or original brick wall) and the tube card shall be secured firmly;

4) Cement mortar painting must be layered brushing, waiting for the grass-roots strength to reach more than 50% before painting the surface layer cement mortar, not a one-time operation;5)The base cement mortar powder must be pressed tightly after compact;

6) According to the requirements of the norms to do a good job of conservation. (Recommended for at least three days).

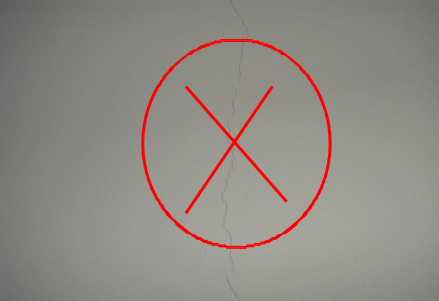

3, the wall appears obvious cracks.

The crack-center line chisels off the wall paint layer, width 20-25cm, covered with thin wire mesh, fixed with nails, sprinkled with water, and repainted with the correct mortar ratio(1:3). Make sure the walls don’t crack.

4, bonding difference, shedding.

The first step is to clean up the surface of the substrate, such as:

The dust and loose materials on the surface of the substrate, release agents and oil stains, which affect the solid bonding of the plaster, are completely removed;

The smooth surface of the substrate is woolly treated;

Blow the water air dry;

A reasonable ratio of water and paint;

Follow the instructions.

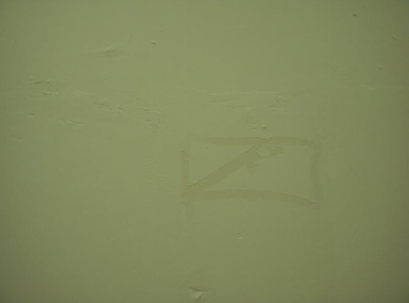

5, the surface has bulges or particles, not clean.

Remove the grass surface dirt, falling mortar, to use shovels or grinding wheel polishing, putty scars and other raised parts of sandpaper polishing flat;

6, paper gypsum board ceiling plate cracked.

1) The selection of light steel keel skeleton materials in strict accordance with design requirements and national standards, keel specifications model should be strictly screened, should not be too small;

2) The boom shall be cold-pulled steel or disc rebar, the length of the boom is more than 1500mm, the back support should be set, the spacing of the boom is controlled within 1200mm;

3) The spacing of the main keel must be controlled within 1000mm, and the end distance of the boom from the main keel must not be greater than 300mm;

4) When installing double-sided gypsum board, the base plate stitching position must be set in the middle of the sub-keel, the seams of the surface plate and the base plate should be staggered, and must not be seamed on a keel;

5) The distance between the self-tapping screw and the edge of the plate must not be less than 10mm, nor should it be greater than 17mm, the spacing of the screws in the middle of the plate should be 150-170mm;

6) The cutting edge of the base plate should be upside down. Inverted requirements: Plate 3mm into a 30-degree angle. There should be a 5-8mm gap between the base plate and the base plate.

7, the embedded seams to fill the gap inside with filled putty filled with not strong medium-dry, do their best to let it dry through, and then paste the seat belt;

8, filling putty construction must be carried out in two. Apply force to press the putty into the seam and compact it to ensure that it is firmly pasted. Wait until the first putty is dry and hard, then make up the second putty and scrape it flat.

9, the second putty dries hard after pure white latex paste cloth or crape paper. Cloth or kraft paper width in the 50mmto60mm range, to cloth or kraft paper all bonded dry hard before the batch of ash cover;

10, artificial seam is a commonly used method to prevent cracks, also known as “to crack”: artificial seam, slotting, wrong seam, segmented seam, large specification plate surface decomposed into small specifications board surface, so that the internal force of gypsum board in the board release, at the same time can also be sewn, groove design Into a different pattern or down, so that the plane three-dimensional, more decorative.

3.4

Wall floor paving project construction technology and prevention measures

Construction process

toilet line (main control line);

Bathroom ground cross main control line;

Bathroom wall bullet line completed;

Bathroom wall tiles;

Bathroom floor tiles;

Bathroom shop finished and finished product protection.

Construction quality general disease and prevention measures

1, outdoor balcony tile shop should not use dry adhesive construction process:

It is advisable to use the wet paste method construction process:

The ground before the patch is cleaned, and after wet watering, 1:1 cement mortar is used, 1:2.5-1:3 cement mortar is leveled, leaving a patch brick Height is controlled at around 12mm-15mm.

The tile should be pre-ejected before the tile line, the brick seam should consider 3mm-5mm,can reduce the scalability.

Using pure cement paste or binder patching, the seams must be tight, the surface is smooth and smooth, and the depth width is consistent.

The ground slope depends on the site elevation, and the ground should be waterproof.

2, plate empty drum:

1) The grassroots should be thoroughly cleaned and rinsed with water, then dried until there is no water.

2) The use of dry hard cement mortar, mortar should be stirred evenly, mixed, must not use thin mortar.

3) Water the mortar before watering wet, using 1:1 cement mortar ( medium and coarse sand ) after the sweep is uniform, then lay the binding layer.

4) The mortar of the combined layer should be firm, kneaded flat, and drizzled.

5) Cement seepage in cement mortar should meet the specification requirements.

6) Before the panel is laid, the plate should be soaked and dried, poured cement pulp or batch pure cement pulp after positioning, the plate will be evenly tap compacted.

7) No upper persons or stacking materials shall be allowed during the maintenance period.

3, toilet, shower room, balcony and other places leakage drainage is not smooth, resulting in the groundwater phenomenon:

The construction team should carry out a comprehensive and detailed technical bottoming work, requiring the control of the floor tiles when the pan-wave processing technology;

Select the construction team with excellent technology to do a high degree of difficulty sub-projects, management personnel to strengthen the supervision of the construction process, to do a good job of construction drainage test, drainage is not smooth to replace the re-post in a timely manner.

4, the corner of the junction, not on a line, affects the beauty.

1) In the process of tile-laying construction, to be side-paved with horizontal detection ruler to detect the flatness of floor tiles, strengthen control of the construction process.

2) It is suggested that the owner should replace the aluminum plate footing with the tile footing, which can improve the aesthetic situation affected by the flatness of the floor tiles.

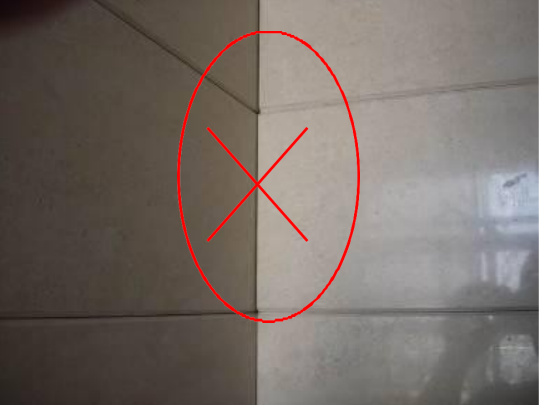

6, wall tiles or marble left V-slots to create black holes at the angle:

Management personnel conscientiously implement the pre-planning work, the team to carry out full technical bottom, and in the construction process to strengthen monitoring;

Correct construction method: Cut a 45-degree angle into the yin corners of a brick wall or stone.

7, wall tiles and windows on the mouth of ugly, affecting the aesthetic:

Project Department earnestly implement the planning work of the pre-closing, draw out the façade of the wall brick layout to the team to carry out the correct technical bottom, and in the construction process to strengthen monitoring and inspection;

Team construction should follow the wall brick layout on the façade after the line, and then paste the wall brick, the inappropriate place should be timely communication with the construction staff;

Solution: Facade layout can follow the size of the wall tiles, consider the window into an L-shaped.

3.5

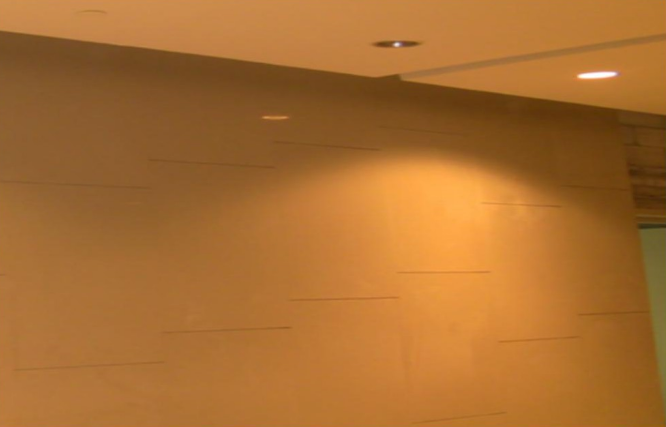

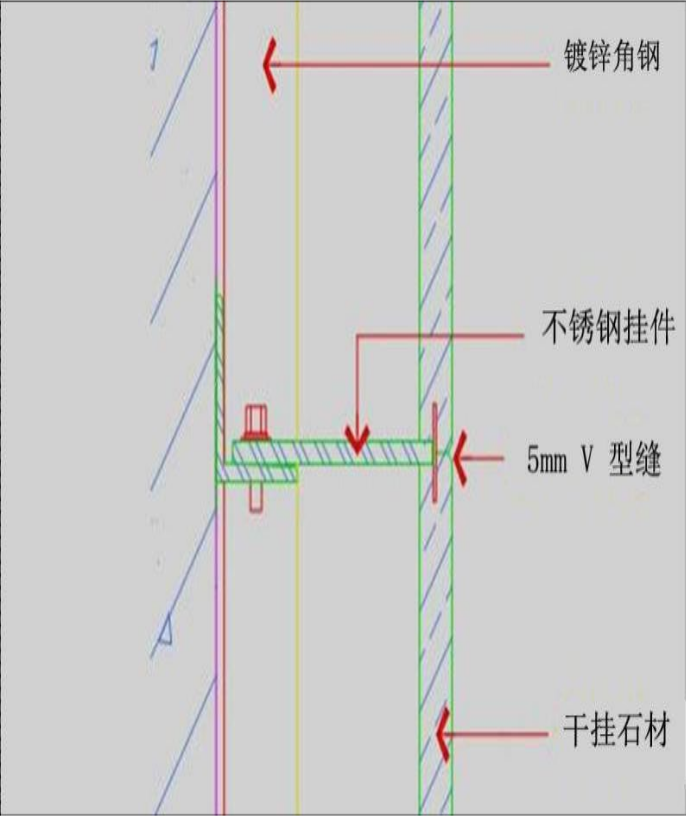

Stone dry hanging construction process and prevention measures

Construction process

Wall divided line;

Installation of steel frames at the grass-roots level;

The first stone installation;

Stone dry hanging node;

Stone finish surface:

Construction quality general disease and prevention measures

1, in the stone rowing plan, to understand the size of the stone wool plate, as far as possible to reduce losses, if the loss is too large, should adjust the design in a timely manner.

2, stone row plate map to be drawn according to the size of the scene. If the stone is a slope or other special-shaped paving, as far as possible set of modules, reduce losses. (A visa is required for wear and tear).

3, in order to ensure the consistency of stone patterns and colors, each piece of factory stone must be numbered. (The number is the responsibility of the factory).

4, stone construction must be pre-arranged according to the number, timely detection of problems, and strive for the best results.

5, the wall design for sandstone stone should indicate the surface to do the breathable anti-fouling treatment. (Antifouling agent to sign the price).

6, cave stone in the construction of a better oil-free cloud stone glue or AB glue installation, to prevent oil seepage, yellowing phenomenon. (Dry hanging, back bolt mounting process can be used.) To sign the price).

7, wall domestic stone seams as far as possible using “V” glyphs or open, to avoid material problems caused by the flatness is not up to standard. Stone “V” type of enterprise mouth and board surface of the yin angle treatment, can not produce a triangular hole.

8, the size of the ground stone paving can not be greater than 800 x 800, so as not to deform the stone. (unless thickened).

9, marble back film mesh to tear off, to prevent empty drums.

10,ground curved stone slicing to indicate the use of professional water knife cutting, factory custom-made. (Water knife cutting is to be signed).

11,wall sheet stone attention to the problem of empty drums. Try to use a special adhesive. (Paster to sign price).

12,the floor mortar bonding layer must be controlled at 2-4cm.

13,the use of wet operation method construction stone should be anti-alkali back coating treatment, because cement mortar in hydration of a large amount of calcium hydroxide, flooded to the surface of stone, produce irregular spots, the production of pan-alkali phenomenon.

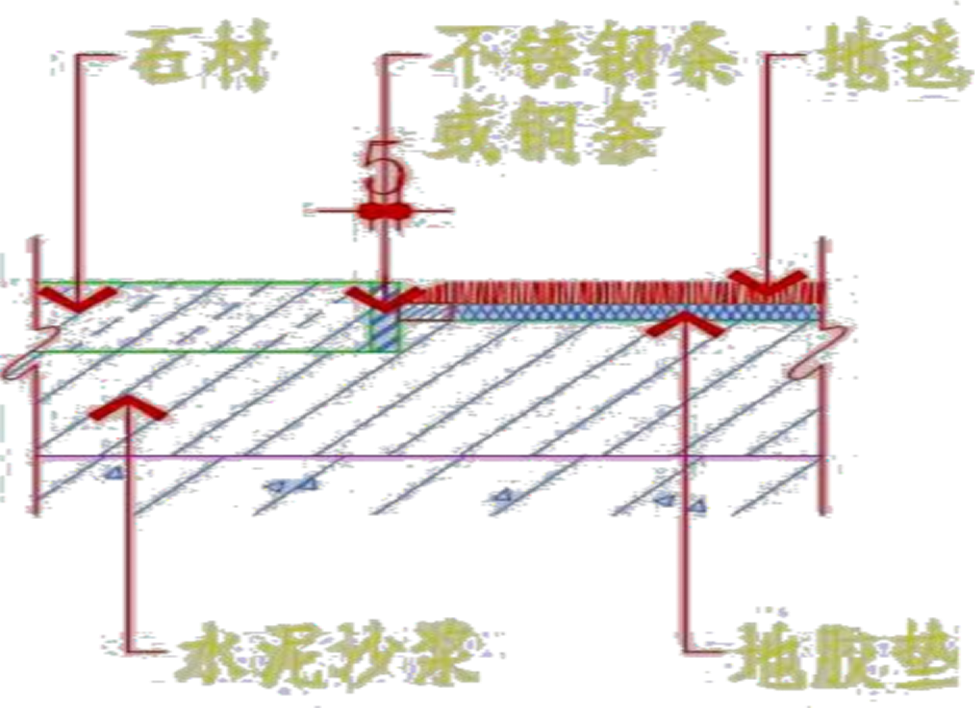

14,ground stone and carpet junction with 5mm wide stainless steel or copper bar closing.

15,stone yang angle treatment, absolutely can not use 45 degrees sharp angle, consider other ways to deal with.

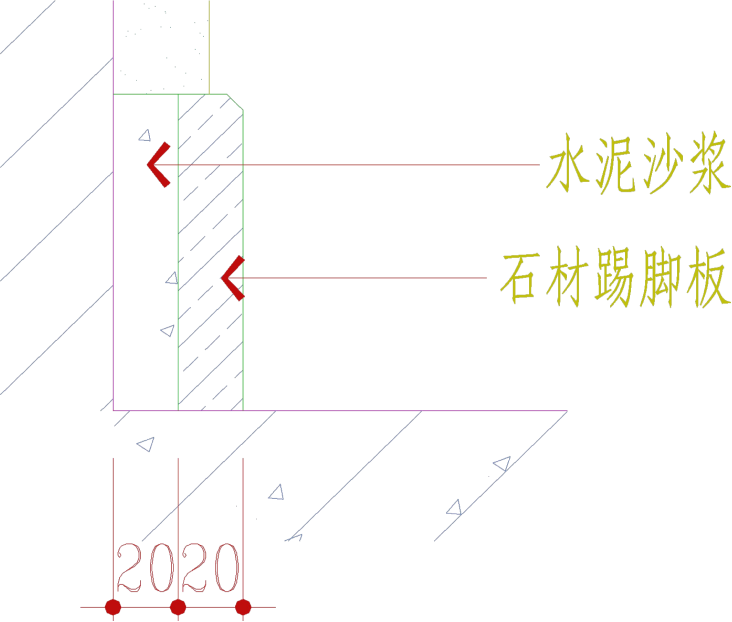

16,stone kick line before construction, the wall needs to be chisel into 2cm. (Request a visa).

17, stone floor or wall construction is completed, it is recommended that Party A do the overall grinding and imported mirror waxing water waxing, in order to play a protective role. (Overall polishing crystal to sign the price) stone to do mirror before, be sure to do a small sample to confirm the quality.

18, marble surface grinding, scratching can not use blades or polisher cleaning, can use wire cotton, or 2200 s water sandpaper gently polished wax polishing treatment.

19, stone floor or wall seams have high and low can not polish the polisher.

20, dry hanging stone holes, the number of grooves, depth, position, size should meet the design requirements. Since the drilling or slotting used for installation on slate is the main part of the slate force, it is easy to have quality problems such as improper position, insufficient quantity, insufficient depth or too thin hole wall, and the quality should be controlled by sampling.

21, for the plate surface, is large and thin plate should be glued to the back reinforced back strip, to prevent warping deformation.

22, fire surface (wash), lychee surface stone anti-fouling treatment, before the factory to do a good job.

3.6

The construction process and prevention measures of the paste project

Construction process

Pour wallpaper glue/wallpaper powder into the water container bucket and stir well, the wall is cleaned, the wallpaper is on the flowers;

Trim excess wallpaper and apply wallpaper glue;

Wallpaper brush glue, wallpaper stacking;

From top to bottom, infrared looking horizontal/vertical straight line, trim top surface redundant wallpaper;

From top to bottom, scrape the wallpaper and cut the excess wallpaper;

Wallpaper to flowers, wallpaper to flower stitching, clean glue.

Construction quality general disease and prevention measures

1, off the seam

Refers to a splicing gap between adjacent wallpapers or wall cloths that exceeds the allowable deviation.

Prevention and control measures:

When pasting wallpaper or wall cloth, must be close to the adjacent frame, strive for seamless, in the catch-up, by stitching horizontal push out glue and bubbles. The same color latex paint can be used to complement the seams.

2, loss of paper or loss of paper or loss of cloth

Refers to wallpaper or wall cloth on the upper mouth and hanging mirror line, lower mouth and kickline is not strictly connected, exposing the base surface.

Prevention and control measures:

According to the size of the length of 10to20mm cutting wallpaper or wall cloth, first of all, the above mouth will be the wallpaper or wall cloth cut well, paste, in the kick line mouth press, cut the excess part; The same wallpaper subsidy can be used at the loss paper office, and the same wall cloth subsidy can be used at the loss cloth.

3, seam

Refers to adjacent wallpaper or wall cloth overlapping bulges.

Prevention and control measures:

Ensure that wallpaper or wall cloth edge straight face clean, paste non-shrinking wallpaper or wall cloth is not allowed to tie, paste shrinking large wallpaper or wall cloth can be appropriately joined more, so that after shrinking just the seam; There are seams, can be used steel ruler press the seam, with a knife-edge cut off the attached wallpaper or wall cloth.

4, warp edge

Refers to wallpaper or wall cloth edge Degluing away from the base surface and rolling up.

Prevention and control measures:

Dust, oil, etc. on the grassroots must be cleaned up;

Choose the appropriate adhesive, brush glue to be thin and uniform, glue slightly dry, and then paste; Raised wallpaper or wall cloth should be turned up, clean up dirt, repainting glue sticky.

5, empty drum

Refers to small bumps on the surface of the wallpaper.

Prevention and control measures: the pressure glue should be inside out, the base surface must be dry, uneven application of putty scraping flat, the base surface dust, the oil must be cleaned up. Due to the damp base or air caused by the empty drum, the application of a knife cut wallpaper, moisture or air out, to dry the base surface, with a medical injection needle will be glued into the drum bag compaction, paste solid;

6, wrinkled

Refers to a wrinkled ridge bulging on the surface of a wallpaper or wall cloth.

Prevention and control measures: the selection of high-quality wallpaper or wall cloth, thick and uneven should be cut off; There are creases, such as glue has not yet dried knots, you can put wallpaper or wall cloth lifting paste, if dry knots, can only tear it off, clean the base surface after re-posting.