The use of test paving for flooring works can reduce the color difference problem, the threshold stone is higher than the floor 1-2mm.

2.9

other

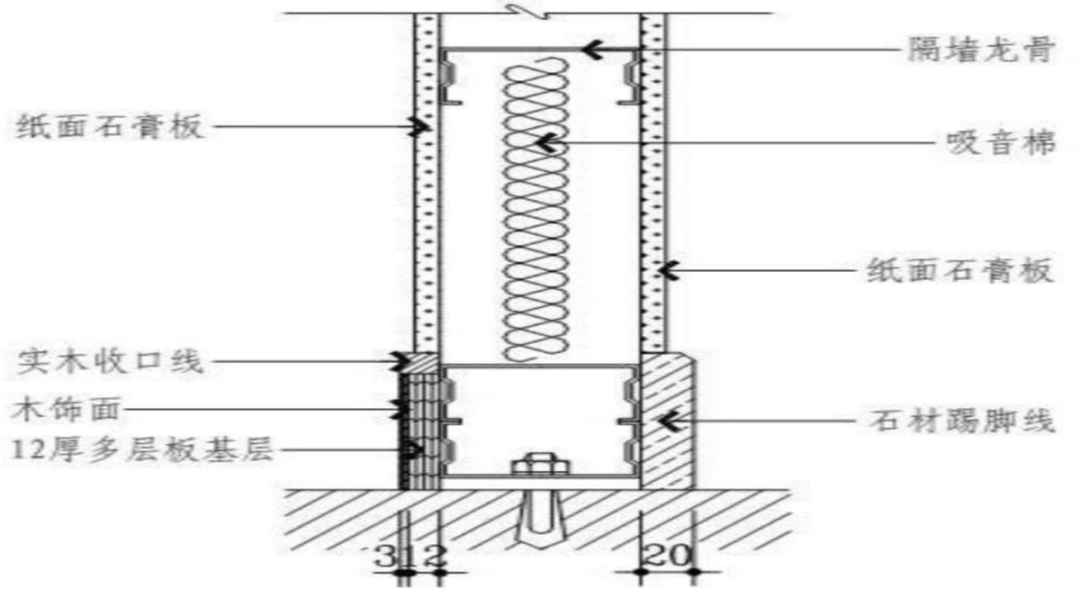

The entry door weight is larger, should be required on both sides for the shear wall or make steel frame grass, to ensure that the door cover base plate installation is solid.

The process is reversed, and the construction organization management problem.

The process is reversed, the ground stone rough grinding is not completed, the wood products have been installed.

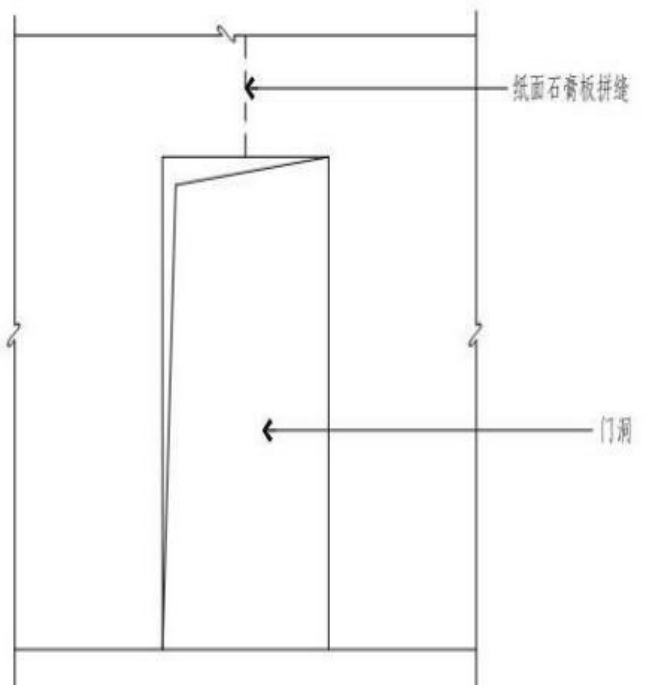

Door opening sealing shall not use splint-type materials as a substrate, easy to crack.

Air conditioning air vents should be sealed strictly to prevent light leakage, try not to take the bathtub stone pressing practice, and pay attention to the inside high and low.

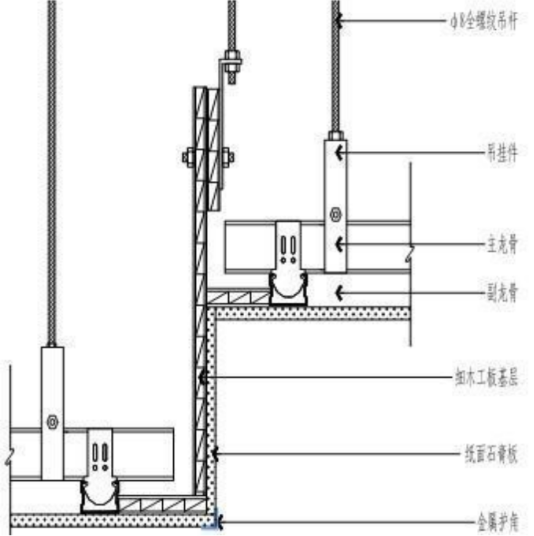

When the construction of a dry wall with stone to the top is completed, the installation of the top plasterboard can be carried out only after the stone dry hanging is completed, and the process shall not be reversed, which may easily cause dangerous sources.

Residential indoor stone must be steel structure dry hanging fixed.

Interior decoration of stone door covers, such as upside-down suspension board, the grass-roots level shall not use multi-layer plate bonding process, must be dry hanging construction.

Residential indoor stone dry pendants shall not use flat plug-ins, T-type parts, stainless steel butterfly parts;

The installation of gypsum line should be like gypsum board installation, the use of self-tapping screws fixed, and should do a good job of rust work, not to use nail fixing.

Conditional projects after the completion of rough grinding of stone, the surface construction before scraping 2 times resin, can effectively extend the time to prevent stone pan-alkali.

03

Common quality common diseases and prevention and treatment

3.1

Common quality common diseases and prevention and treatment

Construction process:

1, put the line: with the laser line caster to release the partition wall line;

2, the ground support mold (rust and moisture-proof effect);

3, pouring concrete;

4, maintenance, mold removal;

5, the installation of heaven and earth keel: with a nail gun fixed tiantian keel to the earth ridge and the original structure;

6, install vertical keel and wear heart keel;

7, sealing one side of the gypsum board: in the plaster board, with pistol drilling, self-tapping screws will be gypsum board fixed on the wall keel and with a ruler to check the verticality and flatness of the partition wall;

8, the partition wall installed wire box and through the line;

The partition wall is filled with rock wool (to be full and dense);

Seal the plasterboard on both sides, the next step is the oilman’s work;

Check that the barrier level, verticality and self-tapping screw spacing to meet the specification requirements, and paste the qualified label.

Construction quality general disease and prevention measures

1, wall keel and wall, cylinder end can not be flat. Can be recessed or protruding, in the field when the line can be timely design adjustments.

2, door holes, window holes around the gypsum plate sealing plate seams must be on the center line, so as not to create cracks in the future.

3, the lower mouth ofthe wall keel is stone or wooden kick board, in the sealing board must be left this space. Wood kick 9 cm board grass care anti-corrosion, fire treatment.

4, the ground did not do the ground dragon and flat on the installation of light steel keel partition wall system, concrete flattened after keel rust.

5, gypsum board did not and find the flat layer empty gap, resulting in plaster board mold.

3.2

Gypsum board ceiling construction process and prevention measures

Construction process

The ceiling is finished with the face line, and the installation equipment is ejected to complete the face line;

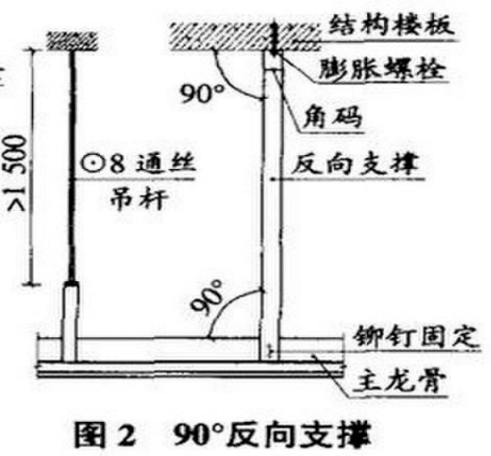

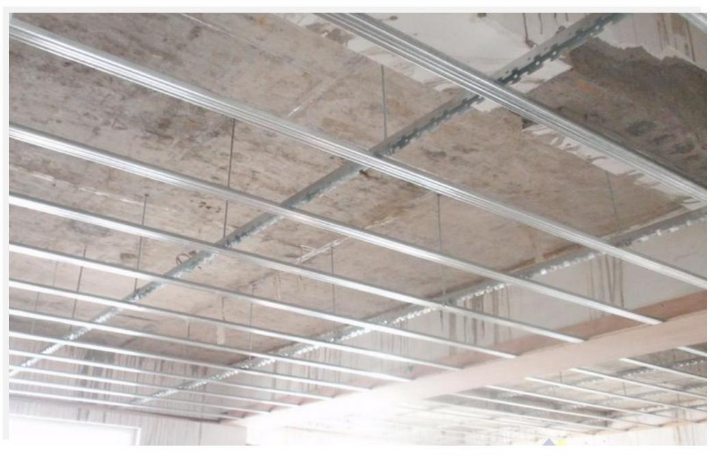

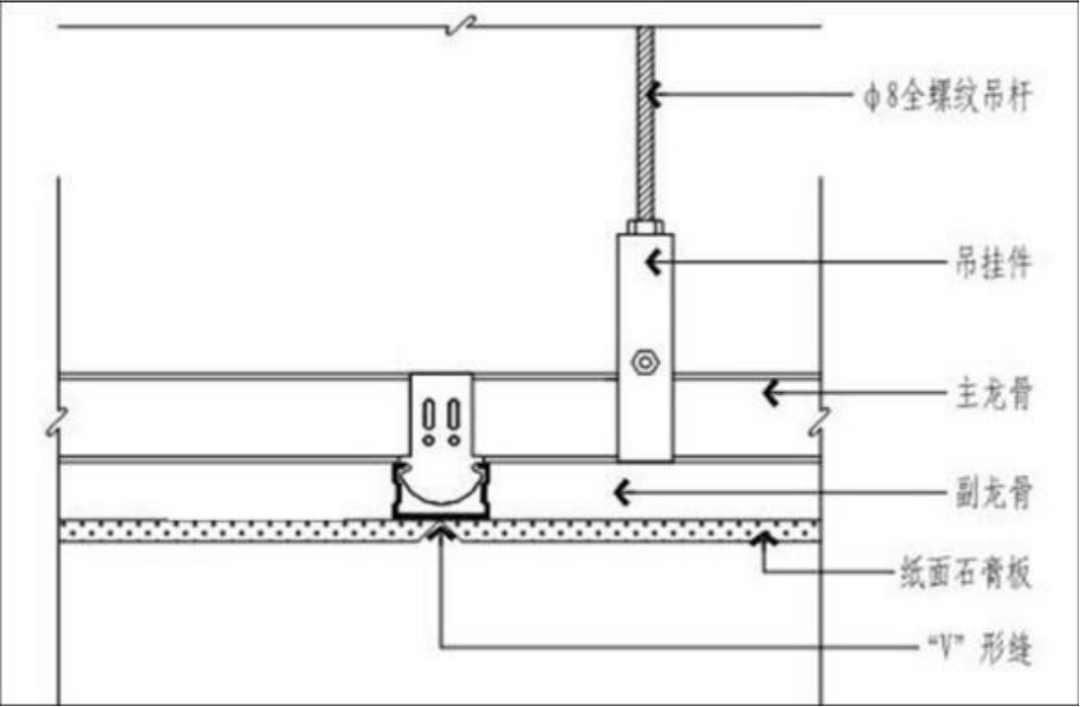

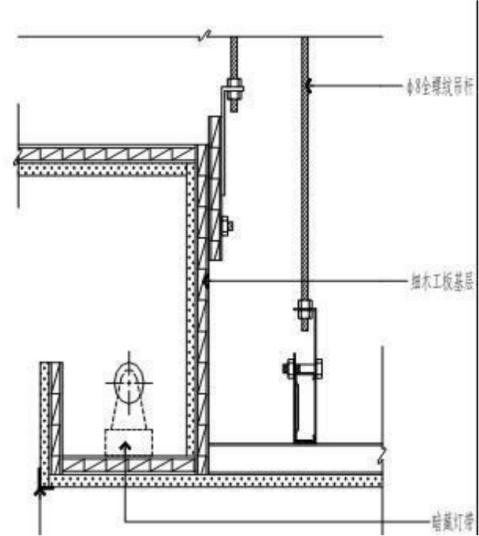

The boom length is installed at the cross, the length of theboom is: φ 8 boom when > >1m;

Installation of the main keel, sub-keel (main keel spacing:900-1000mm; secondary keel spacing:300-600 mm);

Seal the first layer and surface plasterboard;

Construction quality general disease and prevention measures

1, after the start of the project should be in cooperation with other relevant units to actively draw a comprehensive ceiling map, as the top lamp hole, spray, air vents, manholes and other lines of the basis. By us to draw a comprehensive top surface map to obtain a visa to Party A.

2, in the installation equipment under the lighting fixtures and horns, etc. should pay attention to the size of the embedded depth, in advance adjustment or change the design.

3, before the installation of keel, should be in accordance with the design requirements of the room net height, hole height and ceiling pipe, equipment and the height of its bracket for handover inspection. Prevents involvement in the installation of lag operations during cross-construction. (The arrangement of the main keel should pay attention to the lamp holes, spray, air vents, manholes).

4, the processing and installation of the boom:

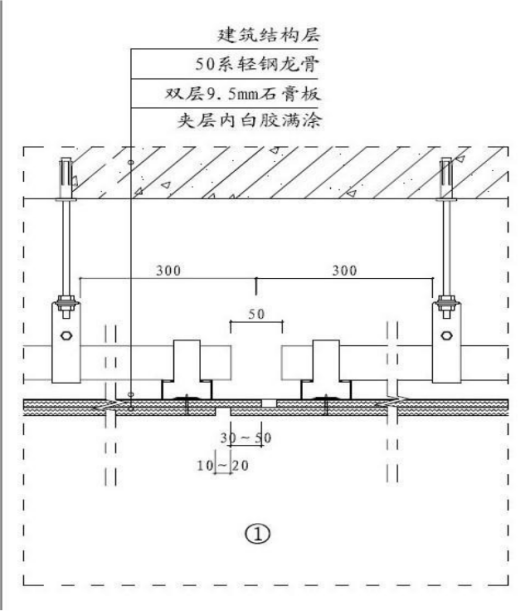

Booms are generally madeof φ6 to φ8 hot galvanized finished threaded rods. Large area or ceiling boom spacing is ≤1000mm,the general ceiling ceiling spacing is ≤1200mm. (The maximum length of the boom, φ6 booms are not greater than 1m, φ8 booms are not greater than 1.5m).

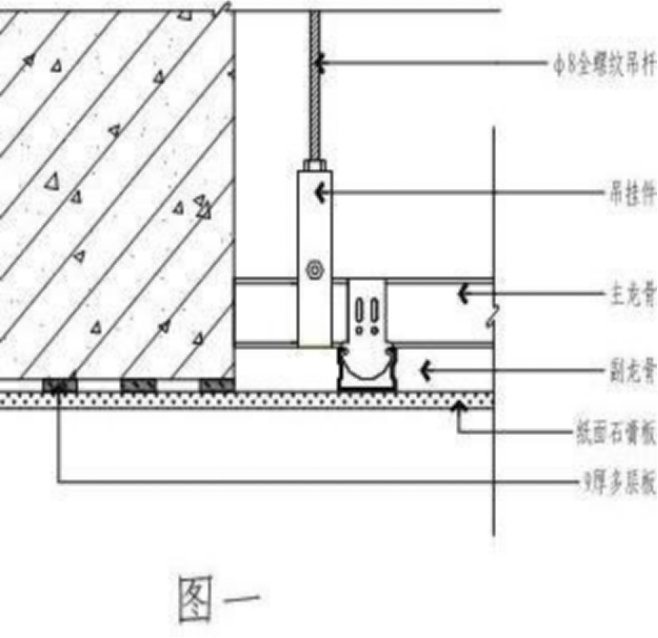

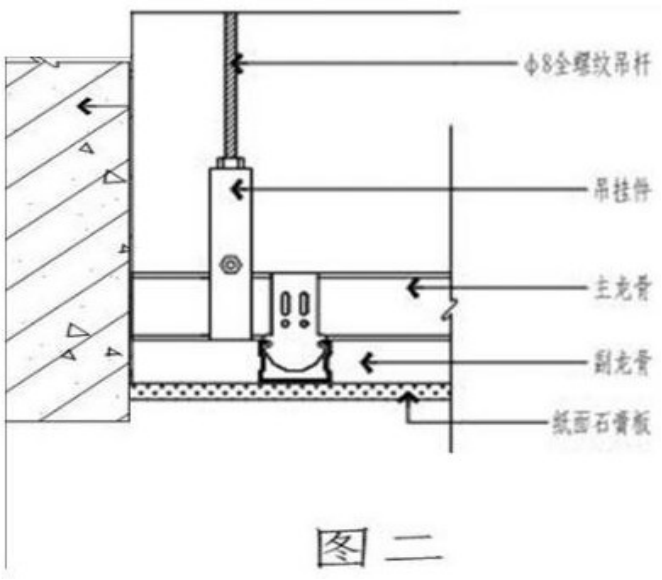

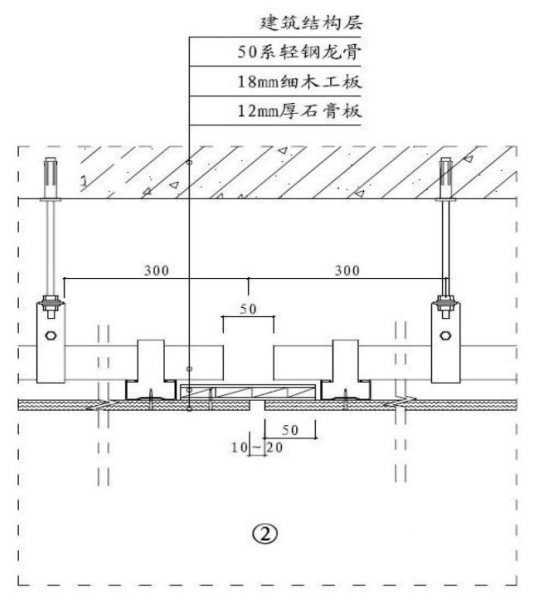

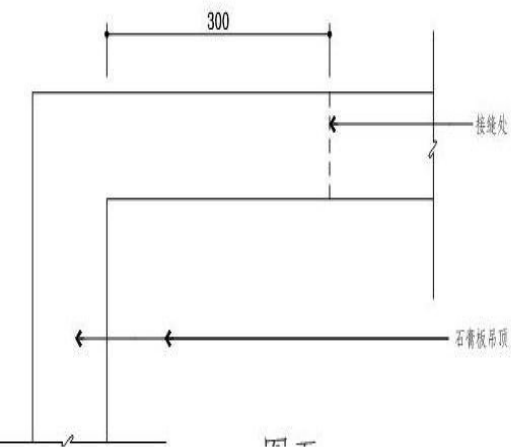

5, gypsum board end surface and beam body and wall end can not be flat, should be in the early line as early as possible to find and make design adjustments. (If the flat interview diagram (1) practice, otherwise see figure (2) practice).

6, ceiling gypsum board straight length of more than 15 meters of all kinds of walkways or large area ceiling corner should be reserved for telescopic seams. The telescopic seams should be added to each side of the construction with two separate main keel and the para-keel must be all disconnected.

7, gypsum board seal, plate seam must be “V” shaped mouth, pre-planed before the board;

8, as a stacking or flipping base of the carpentry board can be used “L” type. The “L” bottom is connected to the sub-keel to ensure straightness.

9, when the boom and equipment meet should be adjusted and added boom, and not with the equipment to share the boom, ceiling should not be in contact with the windpipe equipment. If the equipment or duct is too large to add a boom, increase the production of steel frame over the bridge, cross the bridge horizontal steel frame must not be close to the duct equipment, at least 20mm gap should be reserved. Avoid causing the ceiling co-seismic cracking during late set-up operation.

10,when the length of the boom is greater than 1.5 meters should be set up reverse support, common practice with keel fixed to the floor and 45 degrees with the ceiling main bone dragon anchoring.