2.4

Plastering works

Wall plastering works are most vulnerable to complaints are cracked walls, the reasons are structure, pipeline, hole sealing, ash caused by the empty drum;

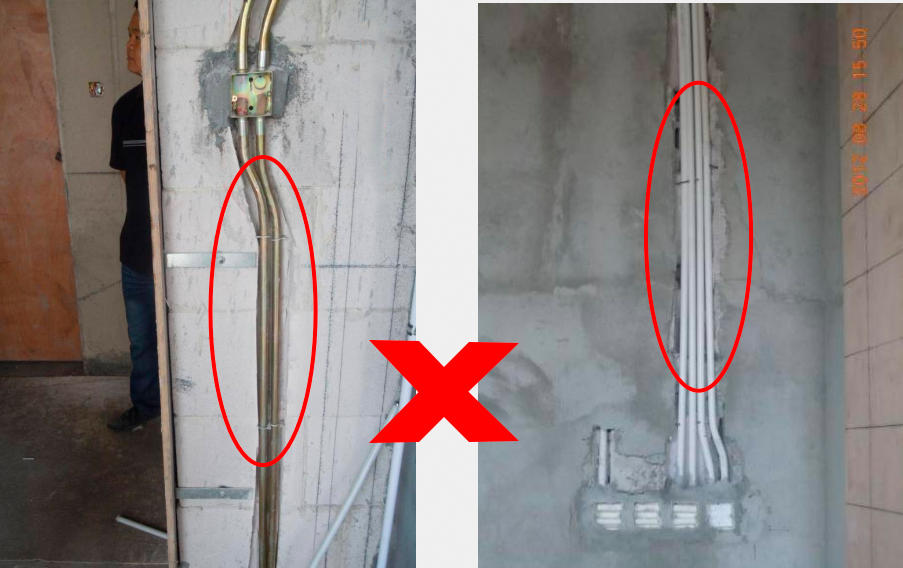

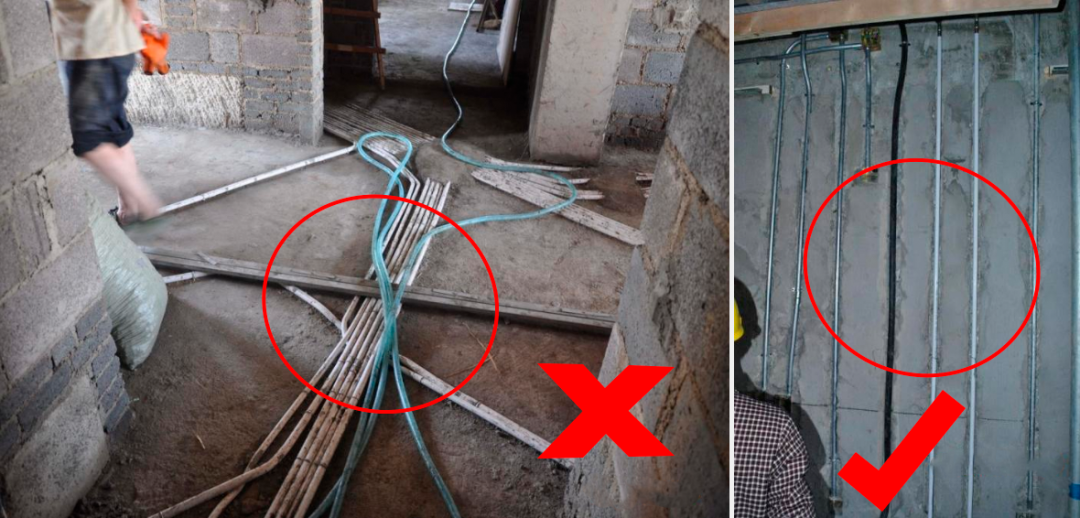

After the wall is slotted, the groove should be cleaned, repainted interface agent, and then lay the wire pipe, otherwise the wall is easy to empty drums, especially multi-line pipe.

After the wall is slotted, the groove should be cleaned, repainted with interface agent, and then laid the wire pipe.

Wall before the batch of ash should be through the bullet line to find out yin and yang angle straight line, to make a batch of ash benchmark;

The wall should be reinforced before the batch of gray, and the first batch of gray should be followed by the installation of kickline, easy to kick line finished product protection.

After the completion of the wall and then install the kick line, it is difficult to ensure that the foot line mouth of the wall straight, the process is reversed.

2.5

Wet work engineering

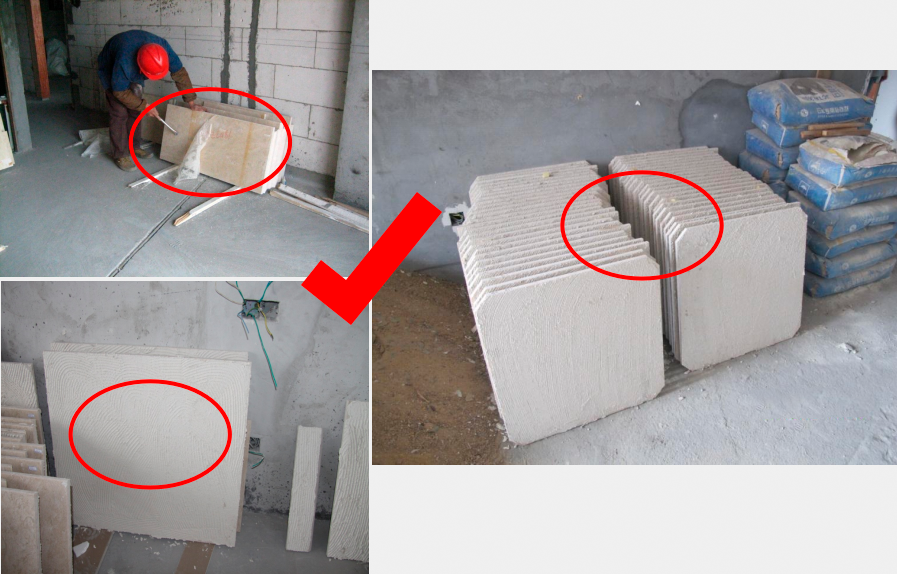

Wet work hardcover repair site management is the core of empty drum problem, stone fracture complaints for hardcover repair complaints the largest number, site management is the most important incoming and unloading stage control.

Large water knife ground collage should be more than a small combination, avoid large pieces easy to cause drum complaints.

On-site construction, cement mortar stirring should be in the mixing tank, to prevent water seeping into the floor of the building caused by stone pan-alkali or blackening of the floor;

Stone floor tile should first shovel the net, then brush the protective agent, and then batch adhesive, to be constructed.

Balconies, toilets and other waterproof areas may not use dry shop construction methods.

Bathroom leveling from the completion surface only 2.5cm,forcing the construction unit can only use the wet shop practice.

Ground stone empty drum using the injection process, after six months by customer complaints.

Wall Yang angle inverted side set aside 1mm undruffed to prevent the edge from bursting.

Unfinished ground stone is an angular collapse and should be protected by edge protection.

2.6

Wood work engineering

Wood products on-site solidity, moisture resistance, process rationality, wood products are mainly complained about in the design scale of irrationality, the smoothness of the use of hardware, scratches and breakages are the most complained about, as the site management process and finished product protection is the key.

Wood products deepen design management negligence, improper detail size, resulting in the function can not meet the use.

Wood products floor floor, no hanging space, ground stone polishing vulnerable to moisture damage.

Wood products hanging from the base, brush moisture-proof paint.

The long part of the kick line should be required, and the water pipe in the basin cabinet should be extended to the bottom of the cabinet.

2.7

Installation works

Installation works are an important guarantee for the function of fine decoration interior, which determines the daily use requirements of the owners, many complaint points, implementability and maintainability are the focus of on-site construction management.

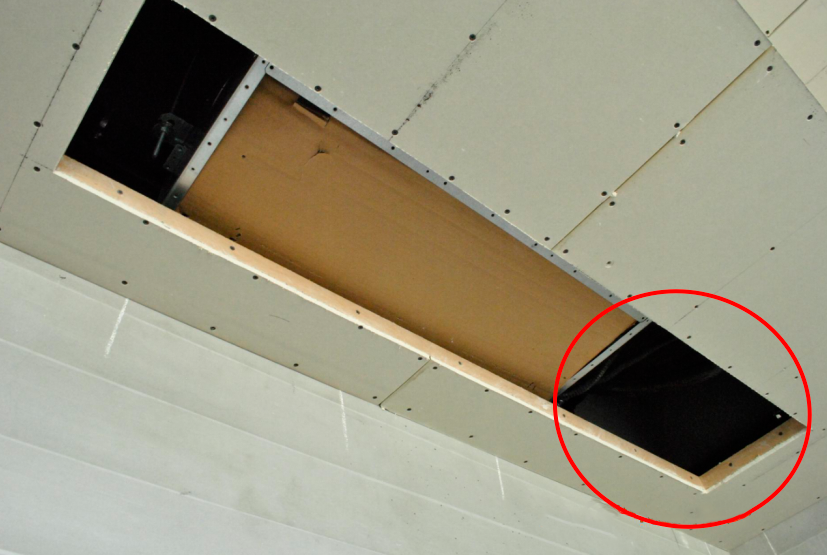

Expand the length of the air conditioning return port for maintenance function.

Switch sockets should be set up in a co-ordinated manner.

Strong wire pipes shall not be laid on the ground, and as far as possible on the wall is laid separately to reduce the wall empty drum.

Balcony leakage as far as possible set on the outside of the building, and has anti-falling leaf blocking function.

Five-eye socket on both sides of the bedroom bed.

2.8

Floor engineering

There are three construction methods in the construction of floor engineering: suspension method (not advocated), mat paving method (mainstream), geothermal method (wet geothermal). Owners focus on: color difference, noise, scratching, environmental protection (off-site management decision), even gaps.

Geothermal flooring is not because of the cost of the reasons, must be laid by a fixed method, not suitable to take the suspension method of construction.

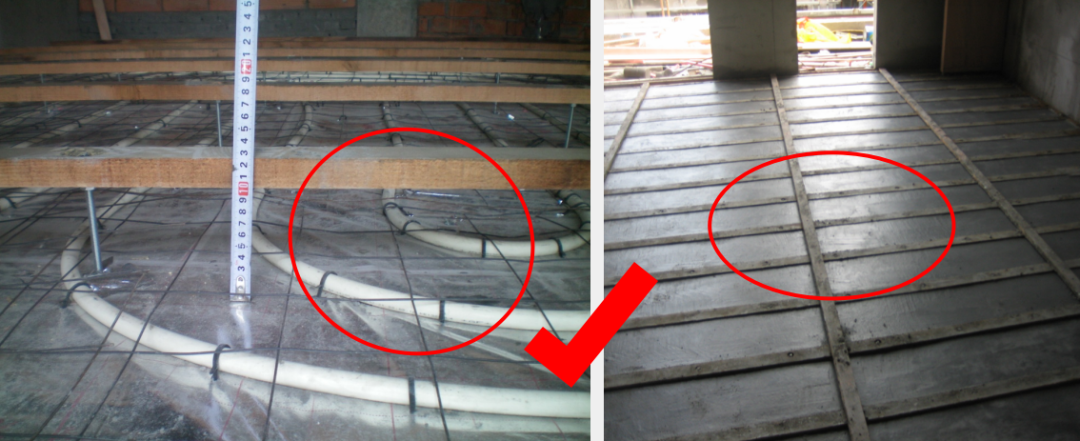

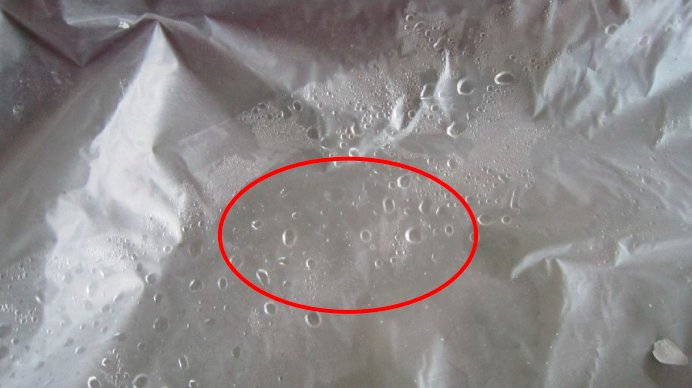

In order to reduce the moisture on the floor, after the installation of the heater to complete the opening of natural gas, the floor before laying the floor of the ground heating protection layer of fine stone drying treatment, through the ground cover plastic film to test whether there is water and gas discharge, and according to the moisture discharge and through the concrete humidifier finally decided that the drying time is about 55 hours better.

Mat paving method can solve the problem of noise well, the grass-roots covert acceptance is the main point of site management.