“Elaborate decoration is the trend! ”

To do a good job of fine decoration, not only to control costs, rush duration, more important and most important is to ensure quality – this is a great test for the project team: small to from kickline practices, socket panel millimeter-level installation standards, large to door covers and wallpaper processes, space square, and so on, Everything is testing the professionalism of the project team.

For quality management points, there are generally the following aspects:

Drawing deepening, material control, labor control, model first, technical points of process engineering and common construction quality diseases and their prevention and control.

This issue to the drawing deepening, process technology and quality of general disease prevention and control three points to expand, and we work together to find gaps, do a good job of quality control management.

01

Sheet node optimization

1.1

Waterproofing works

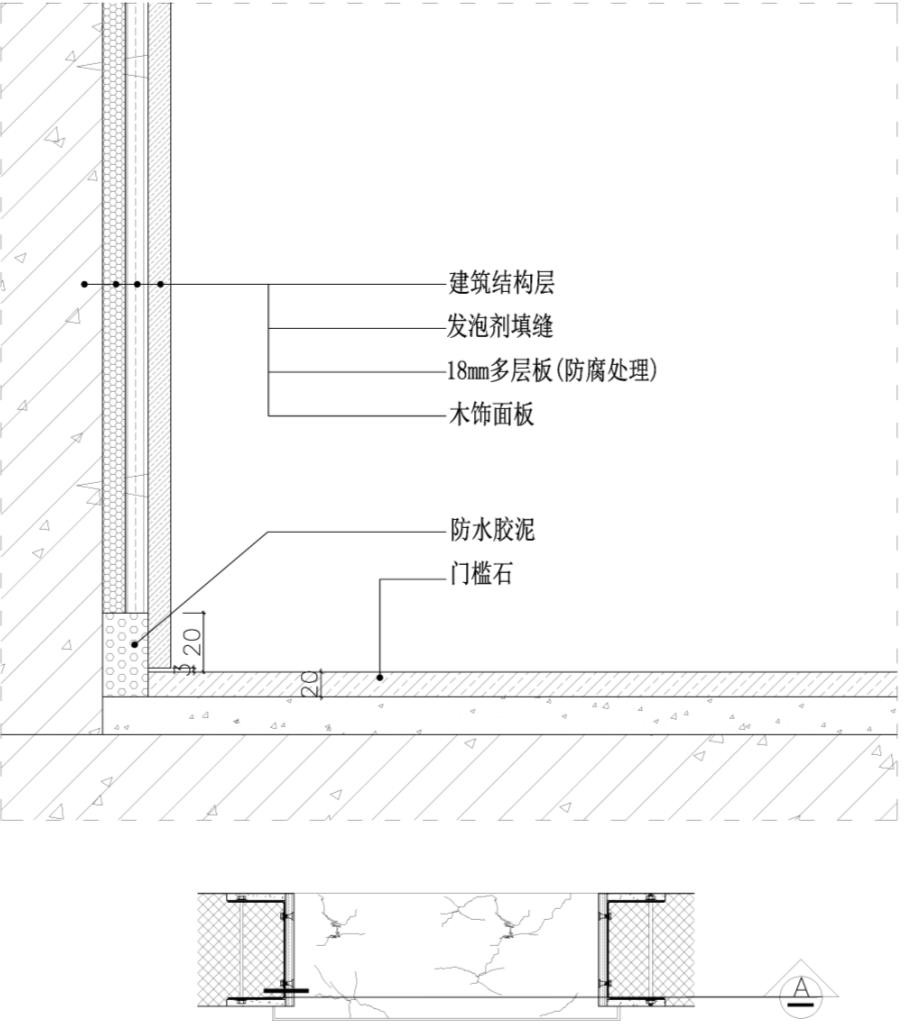

The root of the door cover moisture-proof construction (1).

The root of the door cover base plate should be sewn with the threshold stone surface (about 20mm),the crevice should be filled with flexible waterproof glue, the root of the wood panel should be sewn with the threshold stone surface (about 2 to 3mm), topreventmoisture seepage into the entry set caused by paint finish deformation mold.

The root of the door cover base plate should be sewn with the threshold stone surface (about 20mm),the crevice should be filled with flexible waterproof glue, the root of the wood panel should be sewn with the threshold stone surface (about 2 to 3mm), topreventmoisture seepage into the entry set caused by paint finish deformation mold.

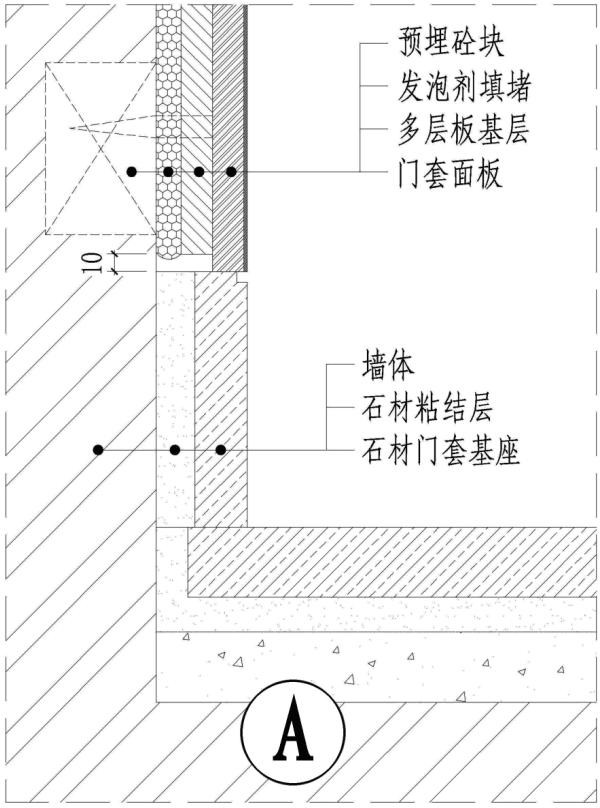

Door cover root Moisture-proof construction (2).

1, this practice is applicable to bathrooms, kitchens, balconies, basements and other high humidity space.

2, multi-layer plate base should do three anti-treatment, and between the stone base should be 10mminterval, to prevent ground moisture penetration into the multi-layer plate.

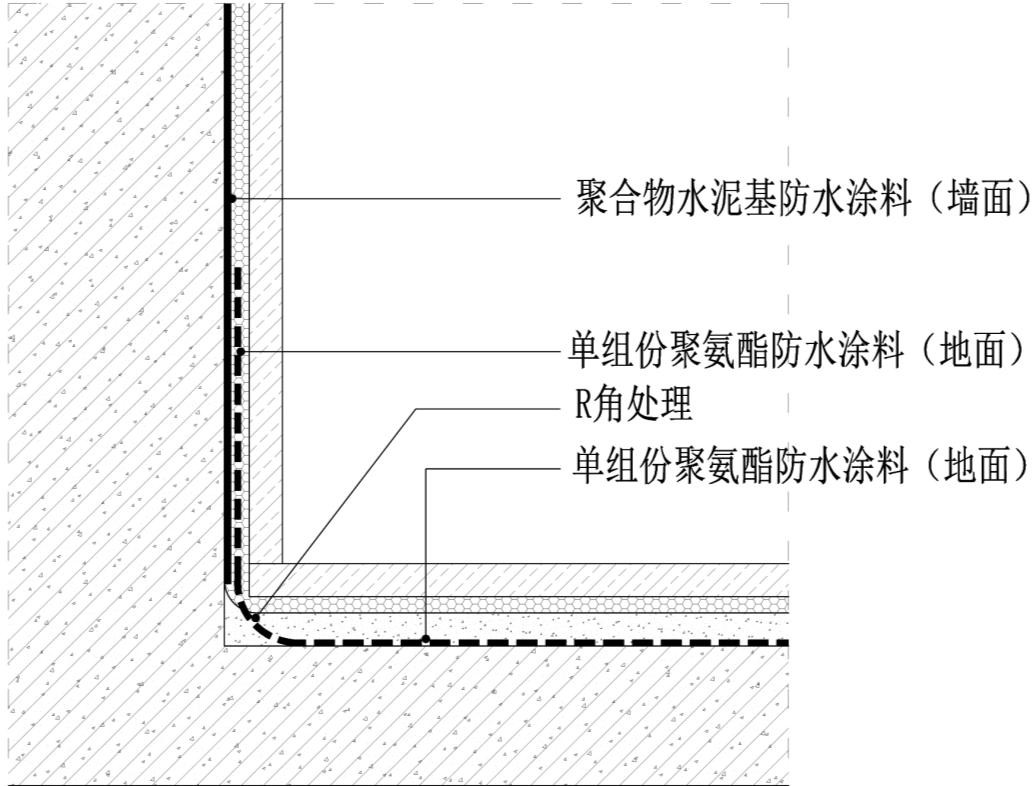

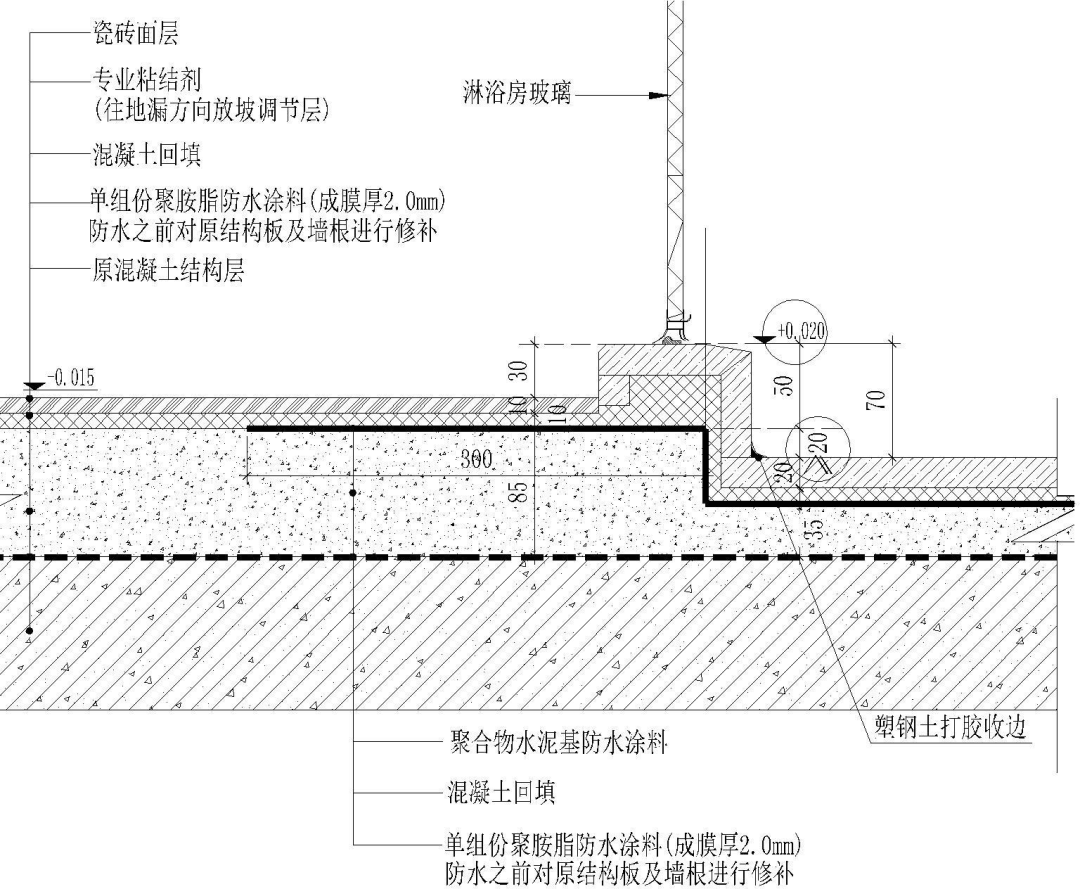

Wall floor waterproof joint construction

1, the wall uses polymer cement-based waterproof coating.

2, wall waterproof paint completed and dried through, can be constructed on the ground waterproof paint.

3, the ground uses a single component of polyurethane waterproof coating, and on the foot of the wall over the ground finish surface 300mm and wall waterproof coating.

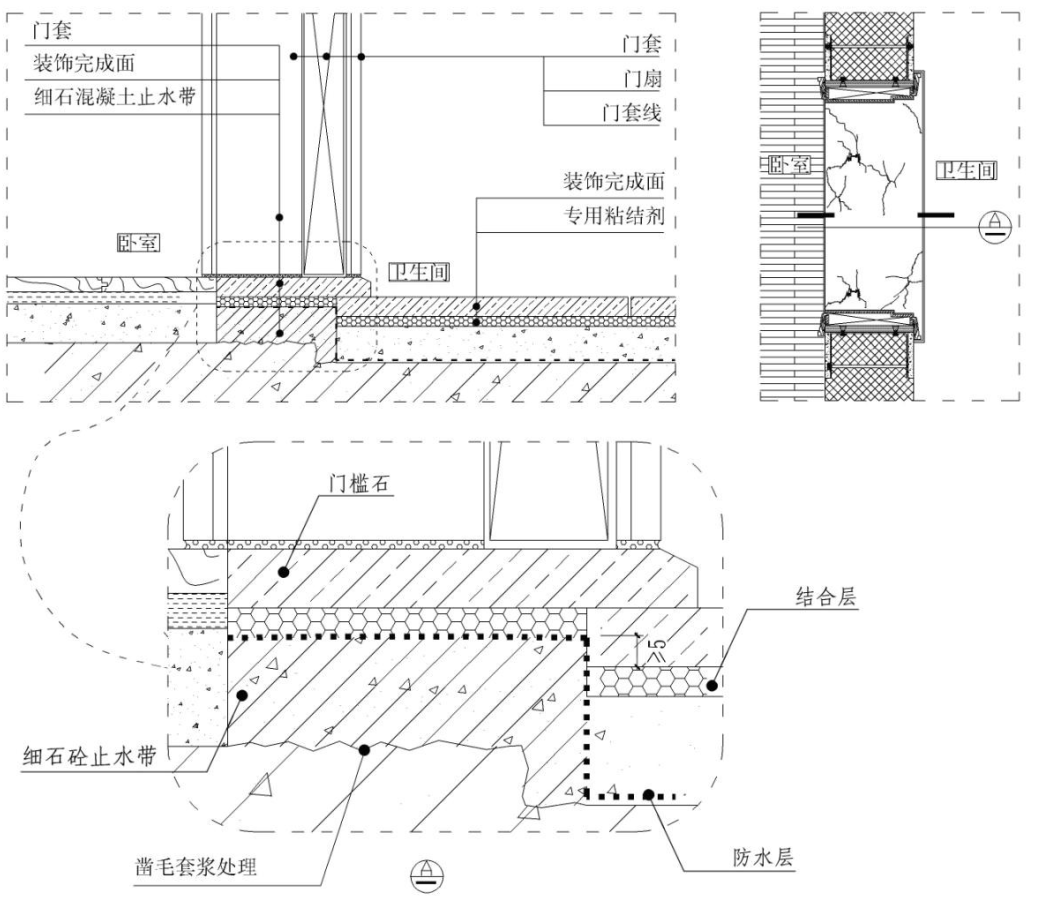

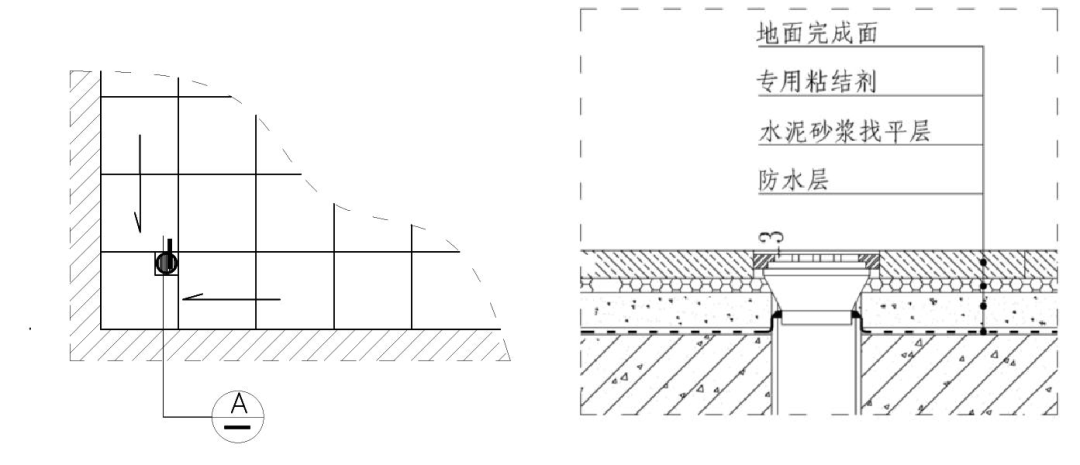

A diagram of the structure of the toilet threshold water stop belt

1, toilet (design has high difference requirements) threshold Stone base should be set up a water stop belt (first in the structure board wool cover pulp treatment, and then the use of fine stone pouring forming), and with the ground to do unified waterproof.

2, the water stop belt should be higher than the waterproof area binding layer more than 5mm.

3, door frame wood grass should be three anti-treatment (fire, anti-corrosion, moisture).

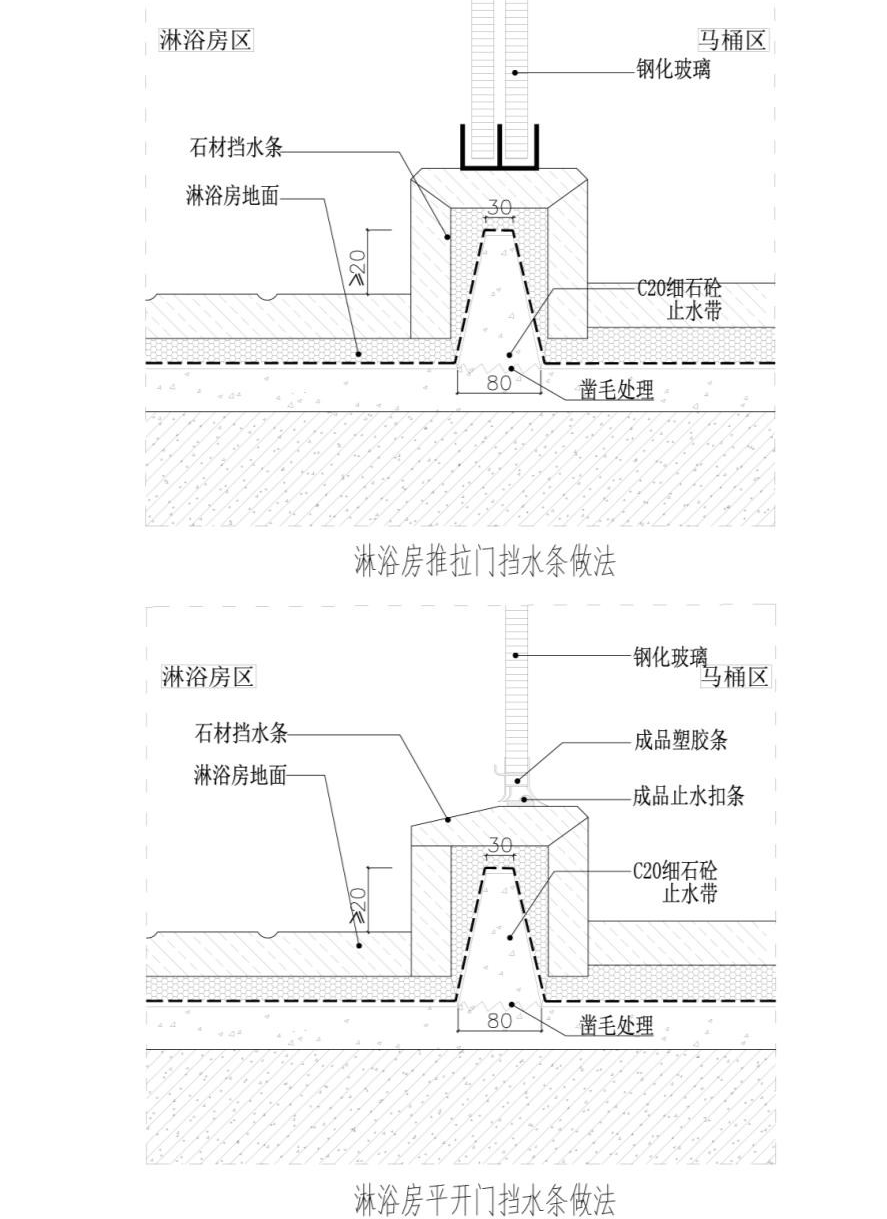

Bathroom shower room water bar construction (1).

1, shower room ground stone should be used wet paving technology paving, strictly prohibit dry paving.

2, shower room water bar should be in accordance with the design drawing requirements in the field elastic line, and set the water belt.

3, the water belt should be located in the ground should be pre-chisel hair, pouring the stop water belt should be carried out grass-roots cleaning and brushing cement slurry together. The completion height of the water stop belt should exceed 20mm above the ground binding layer of the shower room, and the water stop band should extend into the wall 20mmat the junction of thewall.

4, toilet floor waterproof treatment should be carried out after the construction of the water stop belt.

Bathroom shower room water bar construction (2).

1, shower room ground stone should be used wet paving technology paving, strictly prohibit dry paving.

2, dry area ground fine stone concrete flat layer should be higher than the shower room floor decoration finish surface more than 20mm.

3, the toilet should be waterproof construction completed and confirmed by the water storage test no seepage water, and then carry out fine stone backfilling to find flat, find flat should be a molding.

4, shower room water back sill should be on the ground before the spread of a waterproof reinforcement treatment.

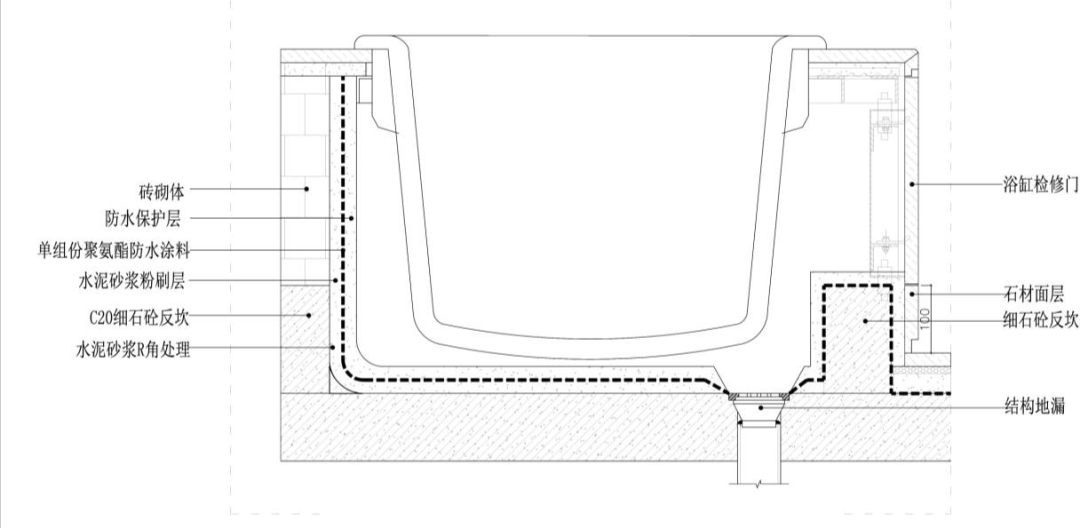

The bathtub waterproof node construction

1, the bottom of the bathtub should be added structural leakage, easy to discharge water.

2, the bottom of the bathtub should be set around the ≥ ground finish surface 100mm C20 fine stone concrete back beam. After the construction of a single component polyurethane should be erased 1: 2 cement mortar waterproof protective layer together. The side of the bathtub should be set up with access to the dark door.

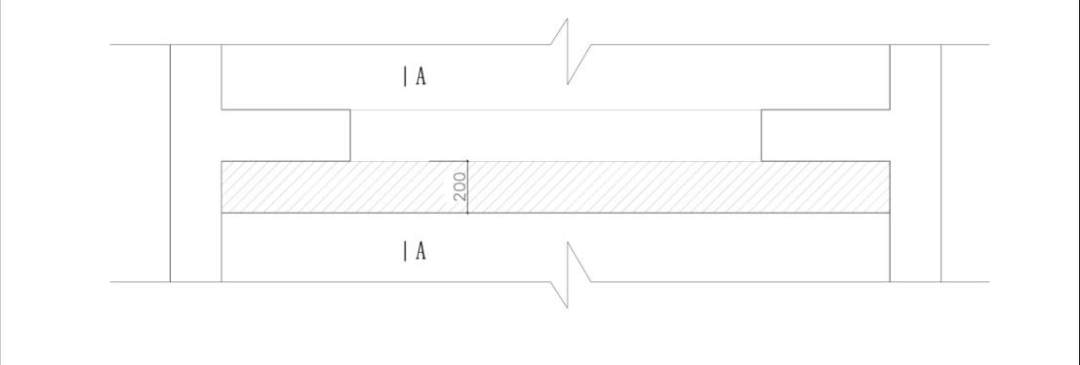

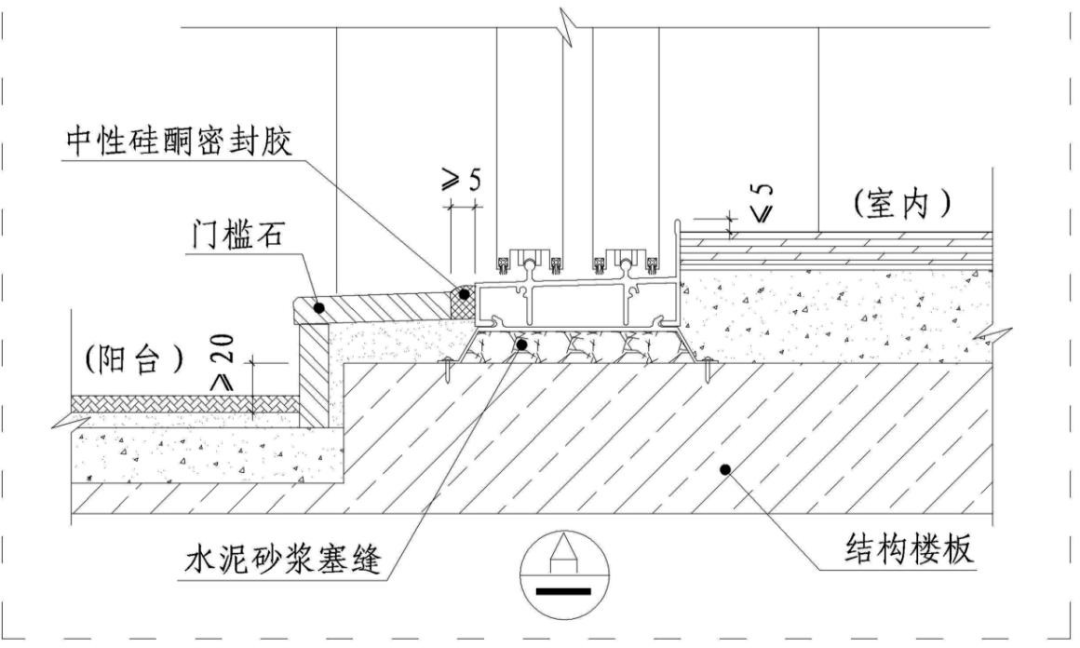

The bottom edge of the balcony aluminum door is constructed

1, indoor floor finish surface should be slightly lower than the aluminum alloy door bottom frame inside (and the height difference does not exceed 5mm). The interior should be set up fine stone concrete water stop, width 200mm.

2, the threshold stone should be slightly tilted (inside high and outer low), the finish surface should be lower than the aluminum alloy door bottom frame outside, and the aluminum alloy door bottom frame junction should be reserved not less than 5mm interval, the gap should be used in the neutral silicone sealant dense filling.

3, outdoor ground combined layer should be lower than the indoor structure floor board surface more than 20mm (if the threshold is set back beam, should be lower than the back beam top surface).

1.2

Water supply and drainage works

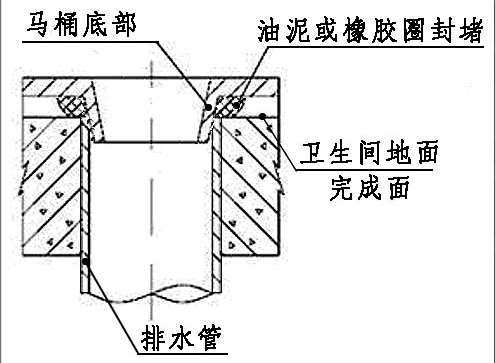

Toilet installation construction

1, according to the toilet selection to determine the toilet sewage outlet reserved height.

2, through the ground around the drain pipe wall and the ground material junction part should be filled with flexible glue, to ensure that the handover part does not leak.

1.3

Wall engineering

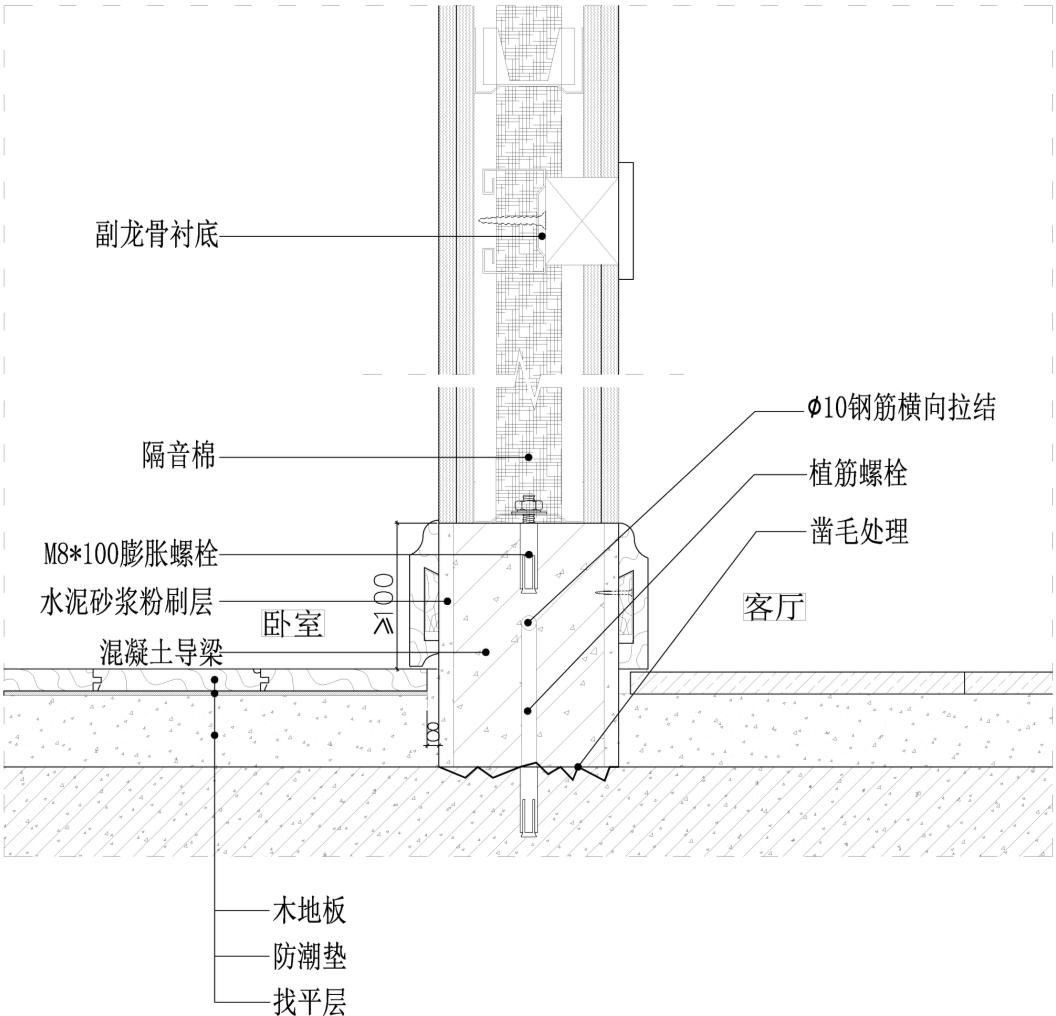

Ground light steel keel partition wall construction

1, wall switch socket Under the back box lined with 50 series sub-keel, in order to self-tap screw fixed switch box.

2, partition wallrebar ground beams, should be in accordance with the design drawings require on-site bullet lines, structure floor pre-planted bolts, spacing is not greater than 450mm (guide wall length is less than 700mm do not do the requirements of the ribs). , between the bolts with a rebar connection of10, molding and mashing edge, turning edge of the ground should be pre-chisel, using C20 fine stone pouring.

Steel frame partition construction (1).

1, steel frame partition wall should be set up concrete guide beam, guide beam height should exceed the indoor floor finish surface more than 100mm;

2, vertical top steel frame should not be hardly connected with the structural floor, the use of bolts and corner code fixed reserved stretch space.

Steel frame partition construction (2).

1, the wall of steel frame and pre-buried iron should be hot galvanized material, welding joints and horizontal round steel should do silver powder paint two.

2, vertical top steel frame should not be hardly connected with the structural floor, the use of bolts and corner code fixed reserved stretch space.

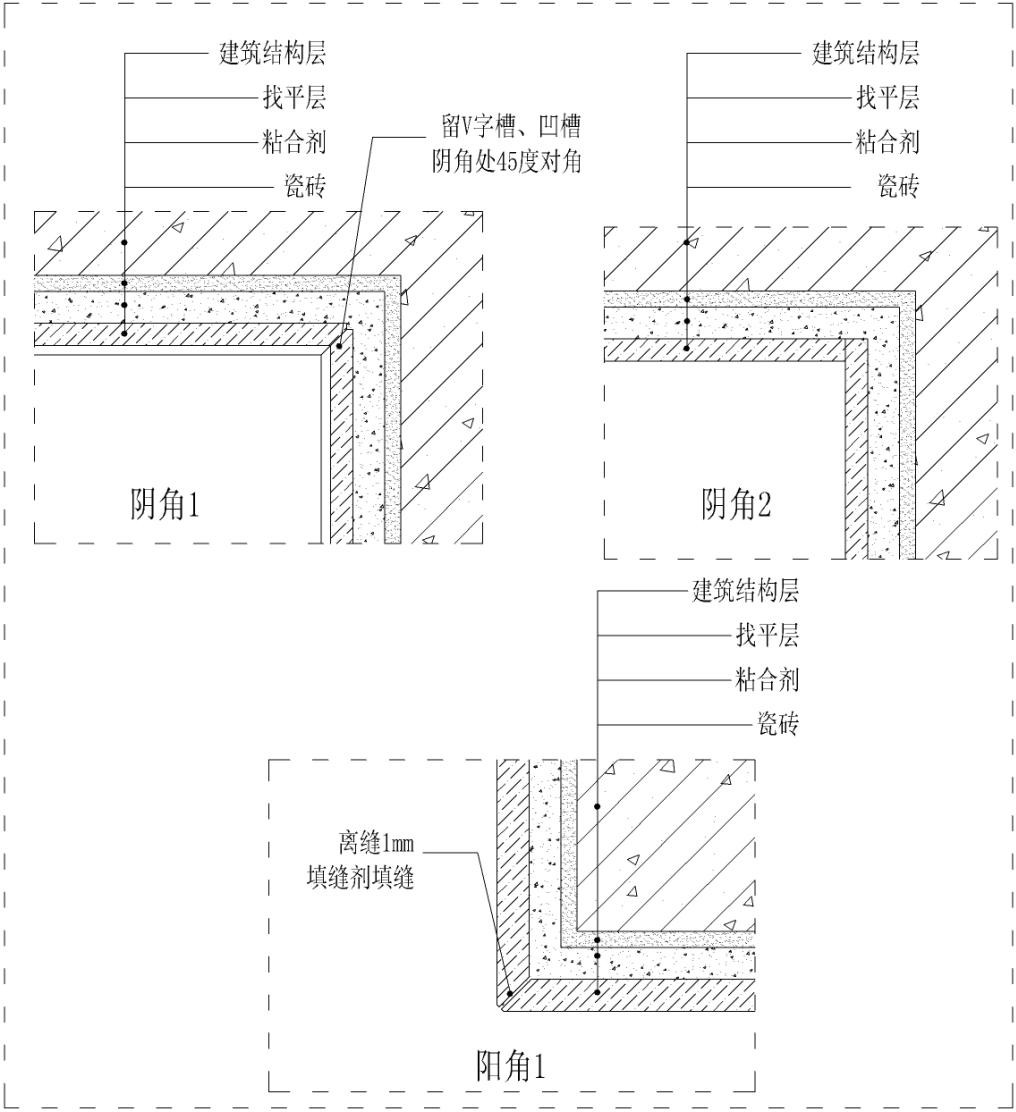

Wall tile yin and yang corner closing

1, wall tiles have cross seams (e.g. V-stitch, grooves), the use of graphic yin angle 1 practice, yin angle closing should be 45 degrees stitching diagonal treatment (angle slightly less than 45 degrees,to facilitatestitching), cut should be processed in the factory to complete (glazed brick can be processed on site) When there are no cross seams, the illustration of the yin 2 practice can be used.

2, wall brick angular closing should be 45 degrees stitching diagonal treatment (angle slightly less than 45 degrees,to facilitate stitching), yang angle incision.

3, should be processed in the factory to complete (glazed brick can be processed on site). Yangjiao closing when spelling should be 1mmaway from the seam, with a filler to fill the seam, in order to prevent the edge, cracking. See illustration of Yangyang 1 practice.

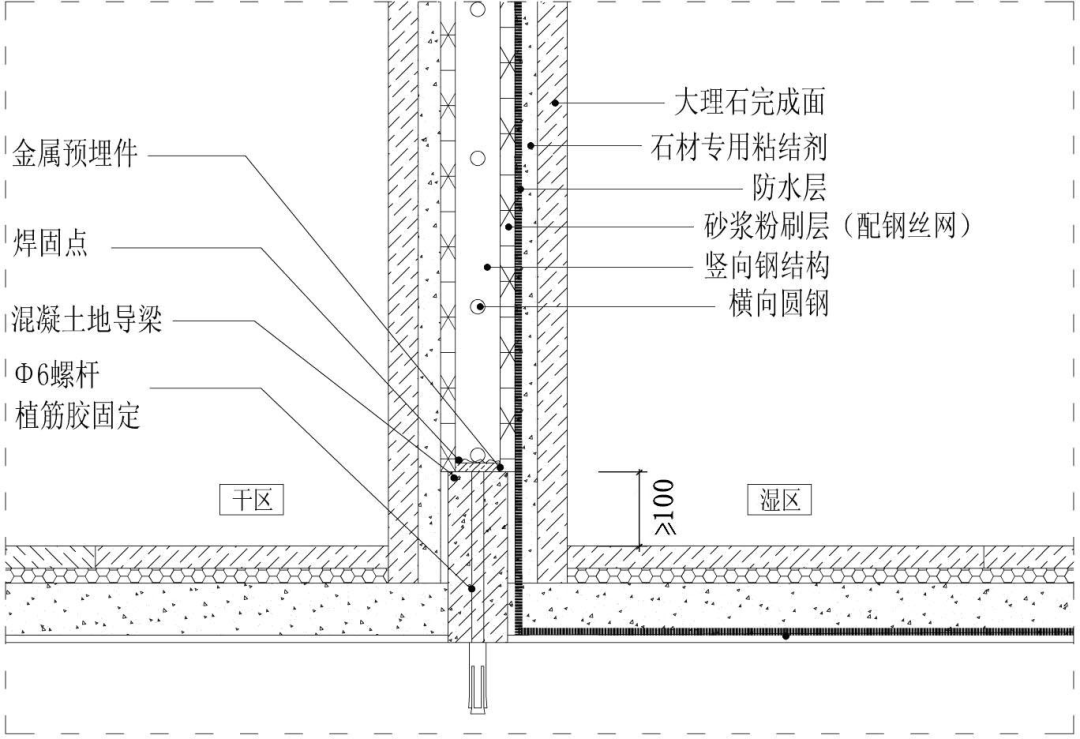

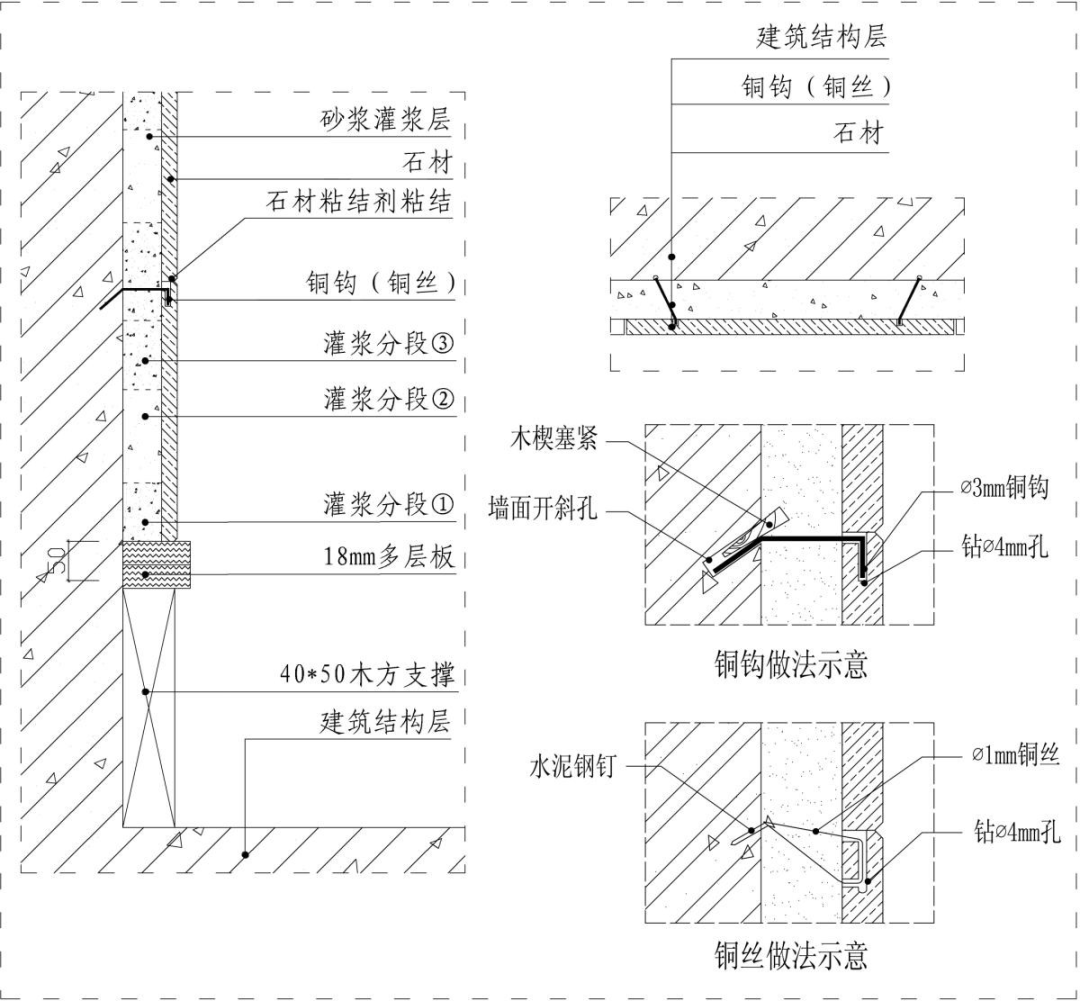

Stone wet hanging structure

1, the wall stone the next unit should be laid on the ground after the installation.

2, wall stone should be ∅ 3mm copper hook or ∅1mm copper wire and wall connection.

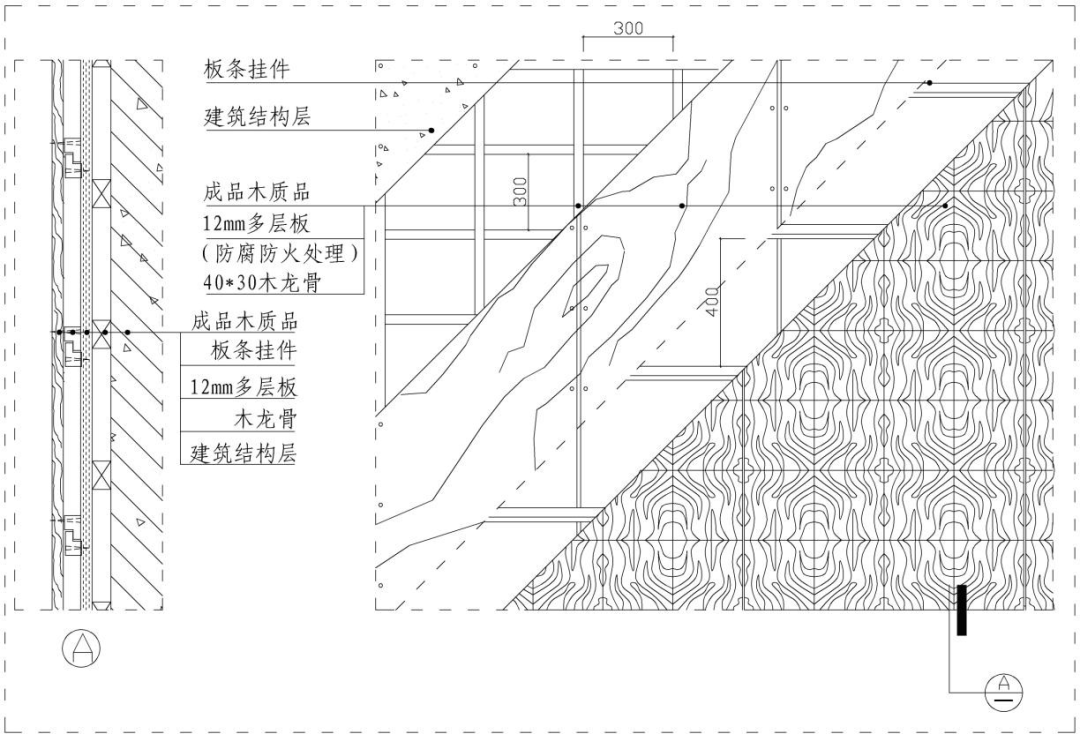

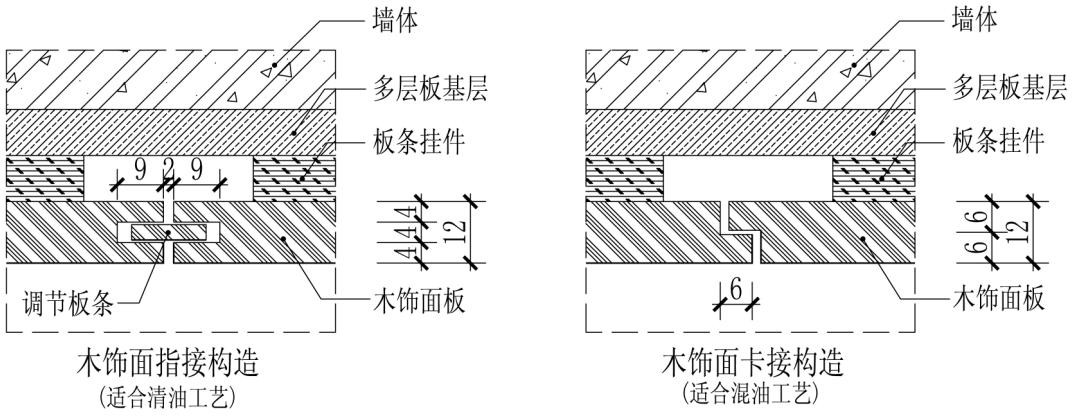

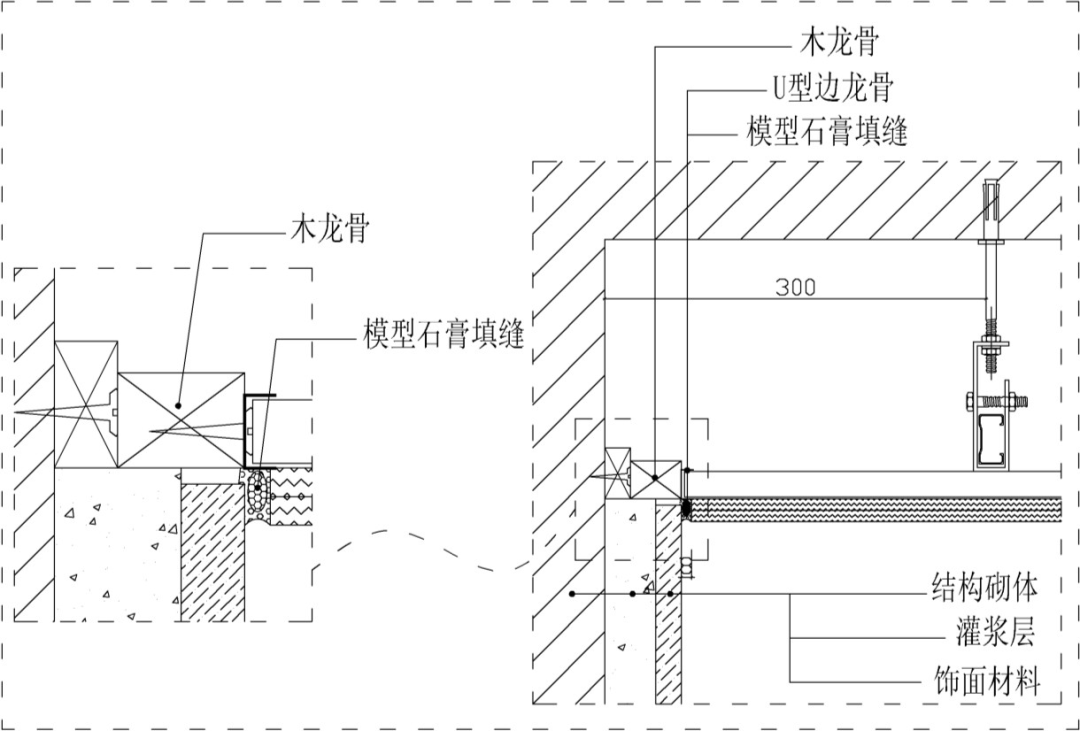

Wall straight board wood finish mount

1, wood finish surface flat, side light check no orange pattern phenomenon. Wood finish 2,seams should be used pointing or card-type process.

3, keel pick 40 x 30mm wood square, installation spacing 300 x 300mm.

4, fixed finish surface layer of the vertical spacing of the slat pendant should be 400mm.

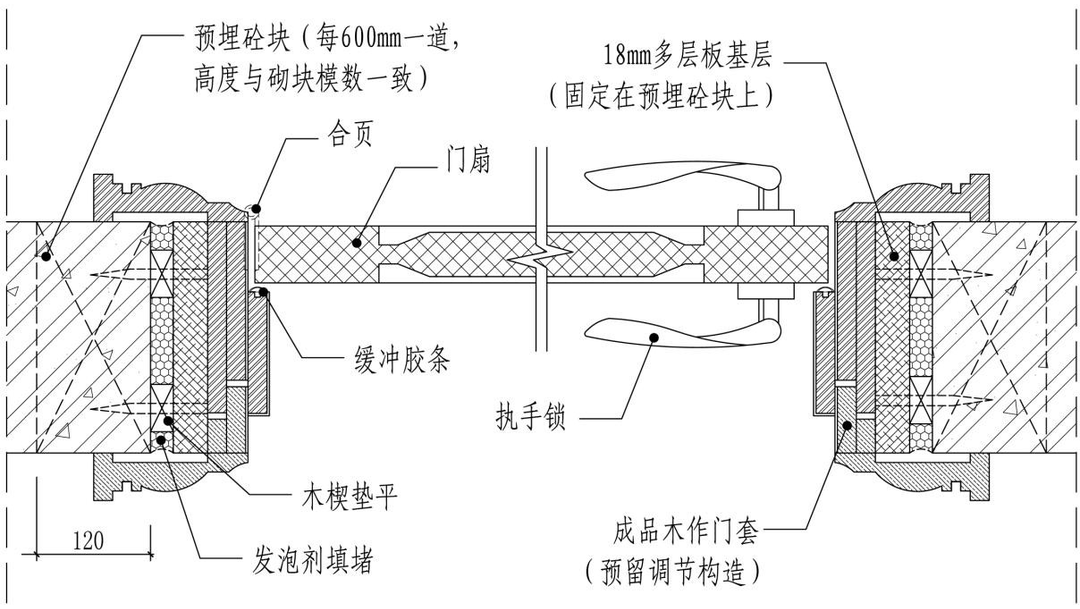

Finished door cover construction

1, masonry door hole, should be on both sides of the door vertical direction up and down not less than 150mm,the middle is not less than 500mm,pre-buried a 120mm wide block, the door frame grass should be fixed on the block.

2, the door frame grass-roots use of 18mm multi-layer board, and three anti-treatment.

Wood 3,the grass-roots board and the side gap of the door cover should be filled with foaming agent.

Bathroom door fan bottom off the threshold stone finish surface 8to12mm,room door fan bottomthreshold stone finish surface 5to8mm. Doors need to be equipped with door suction or door resistance, installation location is determined according to the actual location of the site.

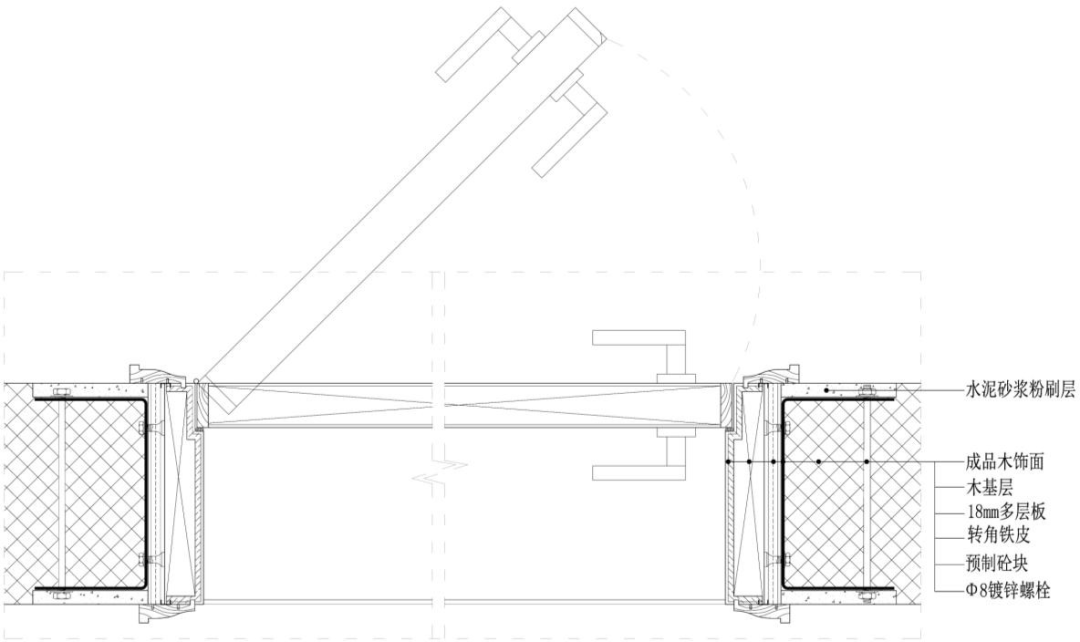

Finished door cover grass

1, lightweight wall using U-type galvanized pull iron sheet, through the wall screw fixed, pull iron sheet thickness should be 2mm,width should not be less than 30mm,door frame and door fan are in accordance with the design requirements.

2, wood floor board and door cover side clearance should be filled with foaming agent.

Bathroom door fan bottom off the threshold stone finish surface 8to12mm,room door fan bottomthreshold stone finish surface 5to8mm. Doors need to be equipped with door suction or door resistance, installation location is determined according to the actual location of the site.

Move the door

1, the door installation height should be higher than the door cover 10mm and ensure that the rail is not exposed, the door under the mouth should be equipped with positioning strip. The hidden door seam width should be greater than the widest point of the door 8to12mm.

2, push and pull door should be set track limiter.

3, the door track above the use of galvanized square pipe welding reinforcement. The door fan should be fitted with a buried handle.

4, two-fan moving door should be made of mother-to-child groove.

5, the door rail should be left with effective access space.

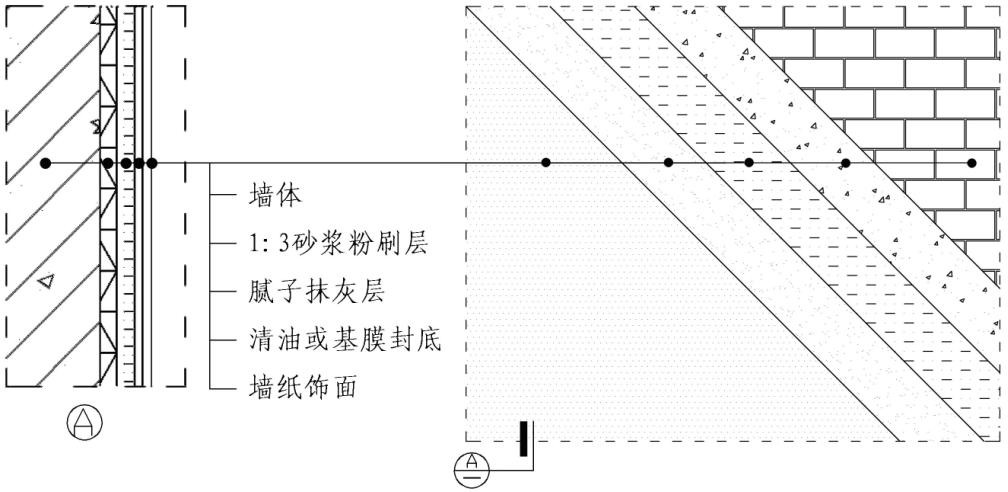

Wallpaper construction

Wallpaper seams, wallpaper and other finishes at the junction of the overflowing glue should be timely with sponge clean water scrub clean, do not apply a dry cloth direct wipe.

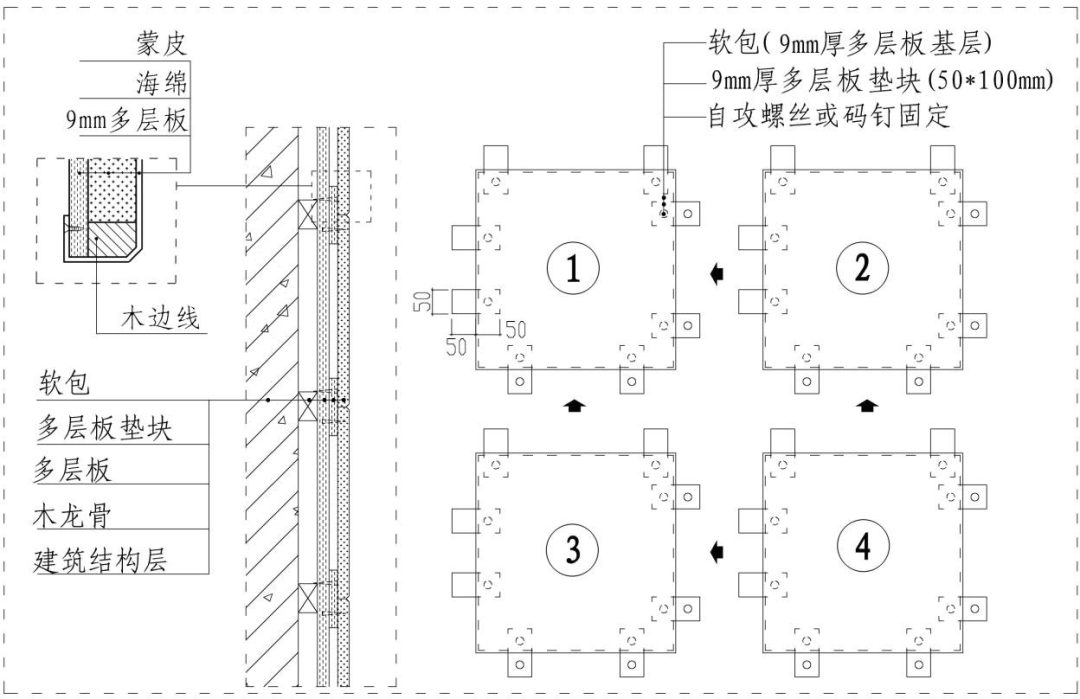

The soft-wrapped finish of the wall is constructed

1, before the soft package production, wall wood as the grass should be separated and numbered, the size of a single piece should not be greater than 800mm×800mm. The back of each soft-pack board should be marked with the number corresponding to the split position of the wall, and the number should be installed at the time of installation.

2, for the shape composed of multiple pieces of soft package, the installation order of the soft package should be carried out from one side to the other side in turn, not from the middle to the left and right (or up and down) sides of the installation. Each soft bag should be backed by 9mm thick multi-layer plate blocks(50×100mm)and installed in turn, as shown in the figure above.

3, soft and hard bag front does not allow the appearance of obvious nail marks, creases, folds.

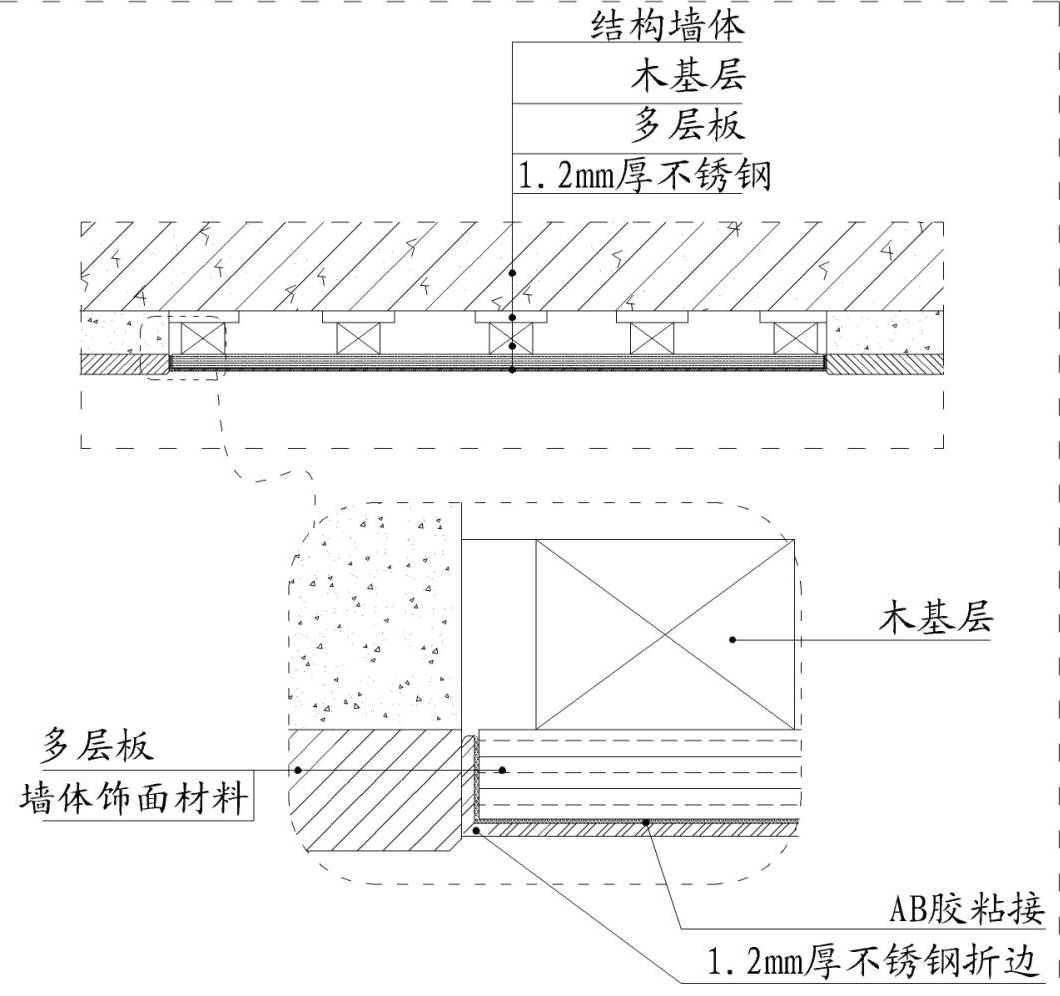

Wall stainless steel and stone outlet

1, wood base using wood square leveling, and sealed a layer of 12mm multi-layer board, wood square and multi-layer board should be fireproof, anti-corrosion treatment.

2, stainless steel should be used 304 , thickness is not less than 1.2mm,should be USED and multi-layer plate bonding fixed.

3, stainless steel finish surface should be slightly lower than tile (or stone) finish surface 1 to 2mm.

1.4

Roofing works

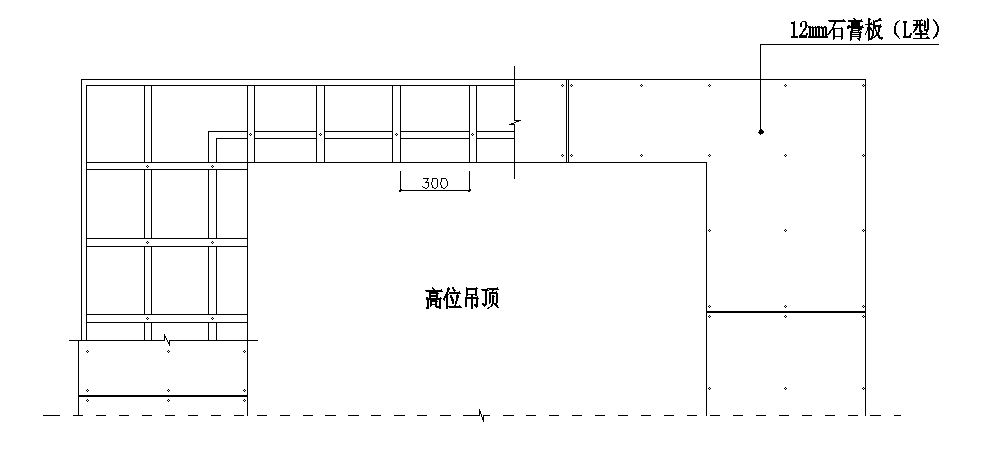

Single-layer gypsum board or calcium silicate plate ceiling construction

1, low ceiling sub-keel spacing should be 300mm,modeling border four corners should be increased oblique keel. At the corner of the low ceiling keel, the surface layer should be L-shaped gypsum plate, and the gypsum plate at the corner should not have seams.

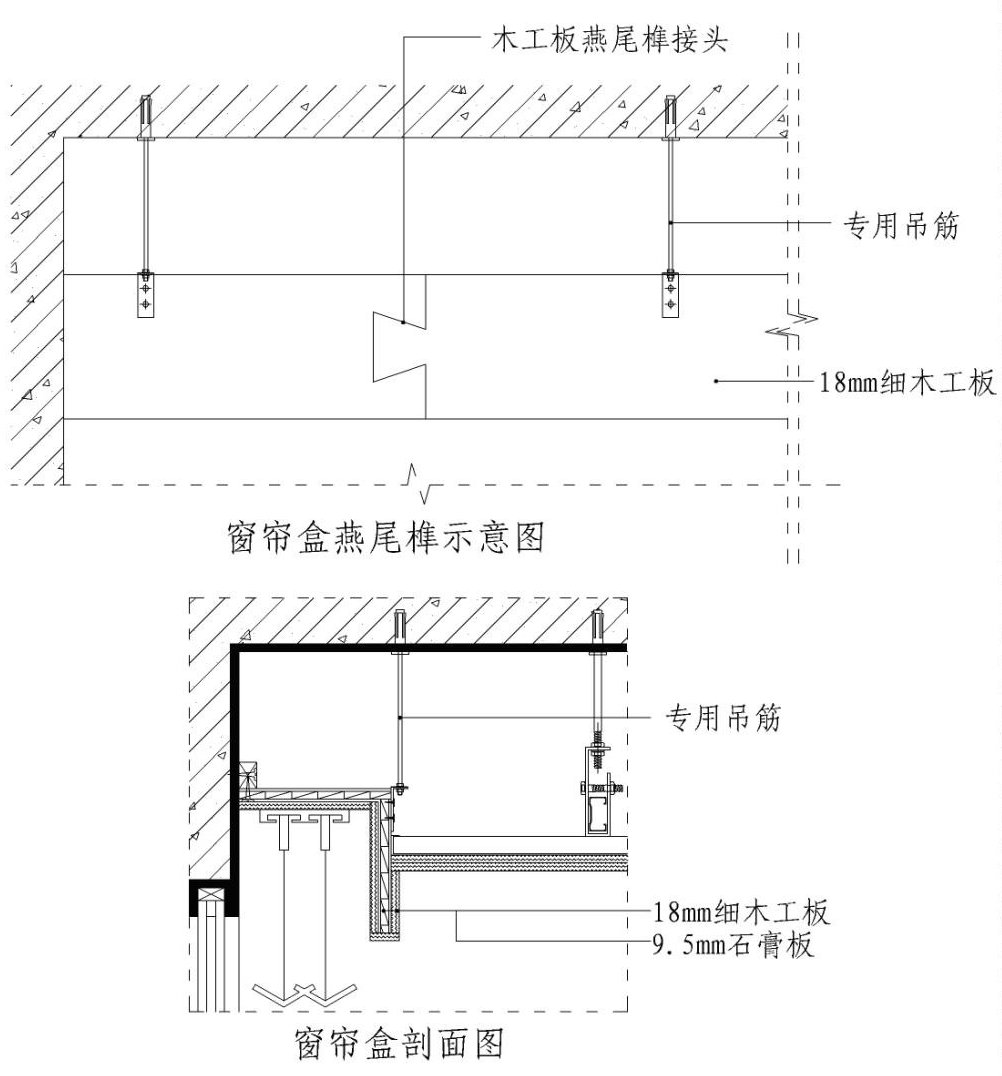

Ceiling wood base production

1, fixed wooden base structure of the boom spacing should not be greater than 600mm.

2, curtain box woodworking board docking application of swallowtails to connect, the back part of the use of carpentry board and covered with white latex for reinforcement, to enhance the overall rigidity of the curtain box, each section of the tie length is not less than 200mm, the use of self-tapping screw fixation.

3, carpentry board outside the grass-roots no other decorative materials construction, should be fire treatment.

4, down-level ceiling side seal height ≥ 200mm, should be set up swallowtail (refer to this practice).

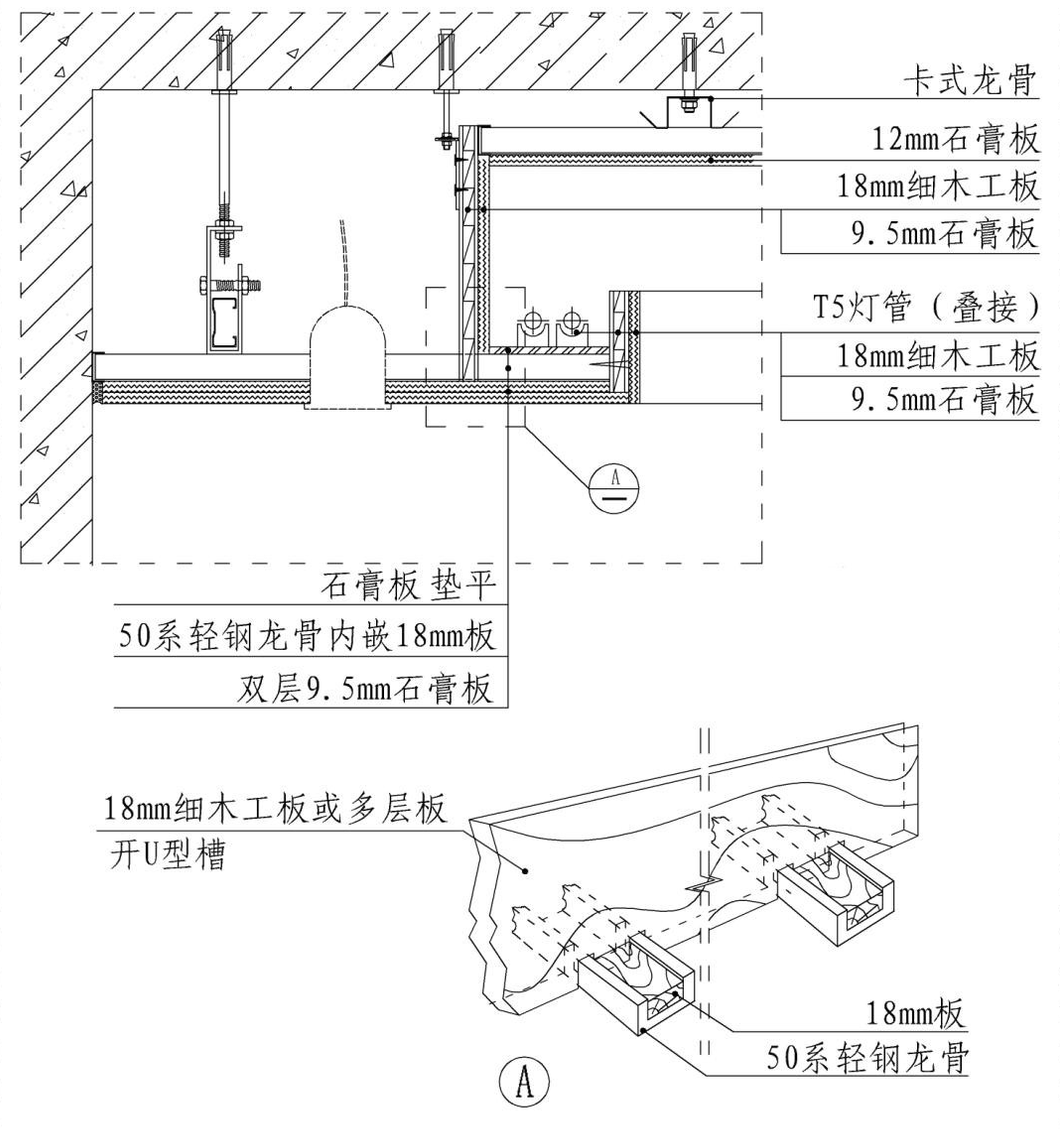

Falling ceiling dark light groove construction

1, smallpox lamp slot inner plate lower port should be U-shaped groove, and with the secondary keel flat, the back of the inner plate and then fixed with pendants. The secondary keel at the lamp slot should be embedded with the wooden keel to increase support.

2, wood base should be fire treatment.

3, the bottom of the lamp slot should be lined with a layer of gypsum board, lamp placed on the plaster board.

Ceiling access (not human).

Ceiling access port should be used finished gypsum access, specifications to meet the maintenance requirements, surrounding keel should be reinforced treatment.

Ceiling access (not up)(2).

Ceiling access port should be used finished aluminum alloy access, specifications to meet the maintenance requirements, aluminum alloy edge should be higher than the gypsum board ceiling 1to2mm,the surrounding keel should be reinforced treatment.

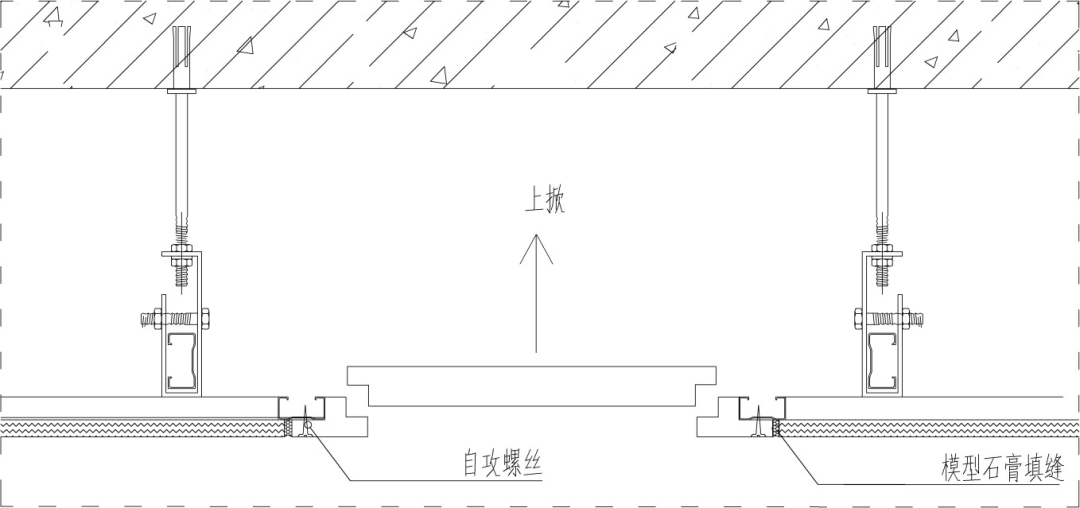

Ceiling telescopic seam construction

1, ceiling unilateral distance of more than 12 meters should be set telescopic seam.

2, single-layer gypsum board ceiling lined with fine carpentry board (fire treatment) and edge keel connection, the lower mouth left 10to20mm seam. The telescopic seams of the lower two layers of the double-layer gypsum board should be staggered 30to50mm,leaving 10to20mm seamsinthe lower mouth.