This paper brings together the general standards and commonly used detailed node practices in the construction process of decorative projects. Through physical photos, simple illustrations and brief process descriptions, the construction process node practices of each section are introduced more intuitively and clearly to everyone. Long space, it is recommended to collect first!

– Wall installation works –

01

Slate wall mounting

1, stone should be processed in advance orders, to ensure that the block of blanks in the natural state has been placed for 3-4 months.

2, stone construction must be carried out before the brick design, should follow the principle of symmetry in the middle, horizontal vertical seam smooth, reasonable circle, beautiful and generous.

02

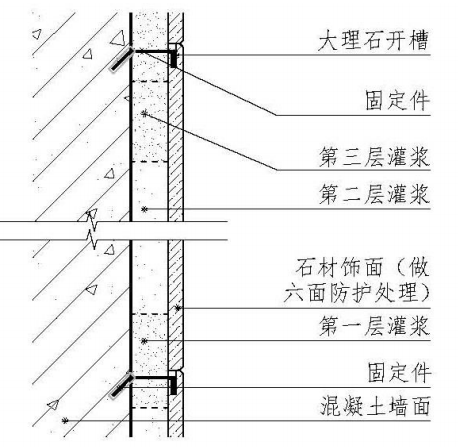

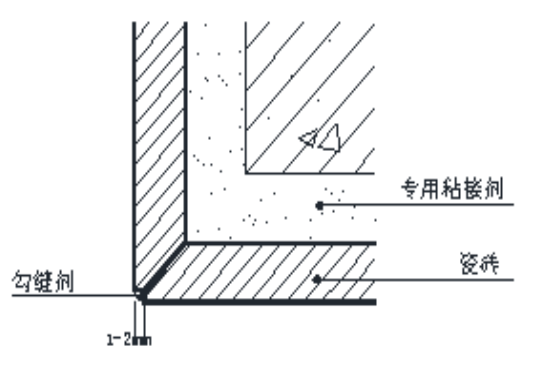

Slate wall mounting – wet paste

1, the surface is flat, allowing deviation of ≤2mm.

2, stone horizontal seam gap straight, tight stitching.

3, wall plate to seam.

03

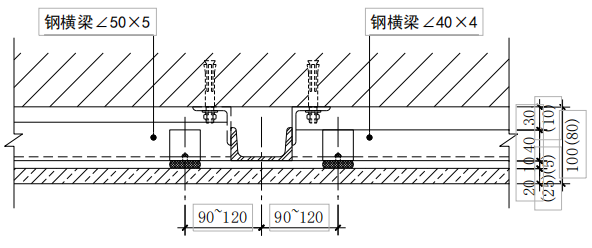

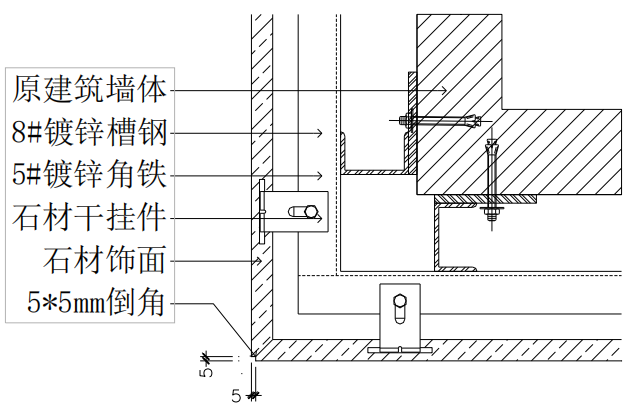

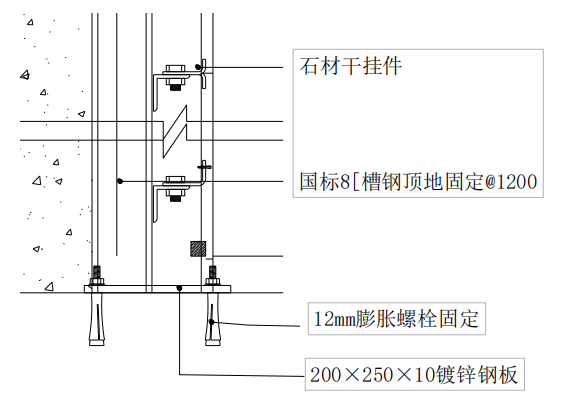

Slate wall mounting – dry hanging

1, the anchor firmware for decorative panels, connectors and dry hanging stone steel frame should be galvanized or rust-proof treatment.

2, marble, granite panel application stainless steel or aluminum pendants.

3, dry hanging stone steel frame must be connected with the main structure, anchor solid, the connection should meet the design requirements.

04

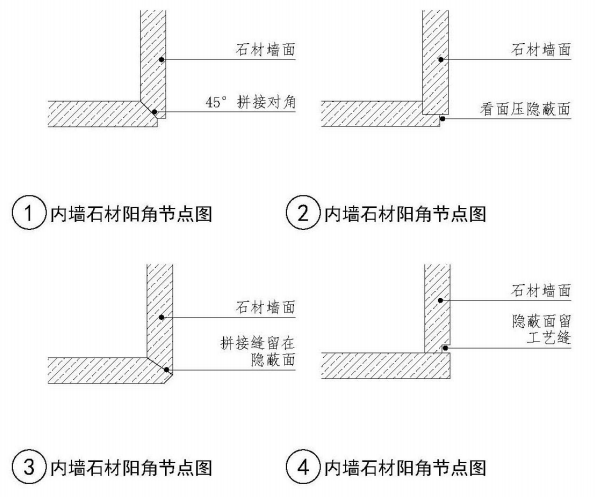

Slate wall mount — Yangjiao

1, yang angle square positive, allow deviation of ≤ 2mm.

2, Yangjiao enterprise mouth docking.

3, yang angle stitching straight.

When the dry hanging method is constructed, the yang angle is generally treated diagonally using the sea otter angle stitching.

05

Slate wall mount — yin angle

Yin angle generally uses a 45-degree angle-cutting pressure receiving port, there is a horizontal process seam of stone should use cross-outlet mode.

06

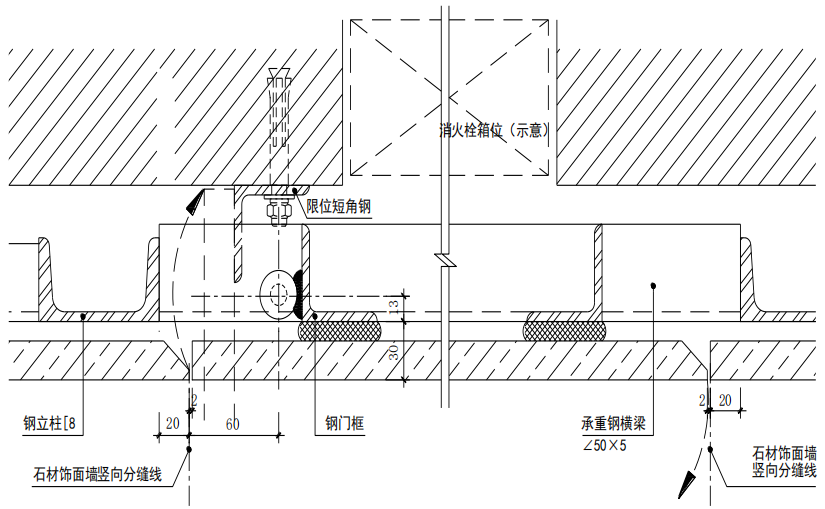

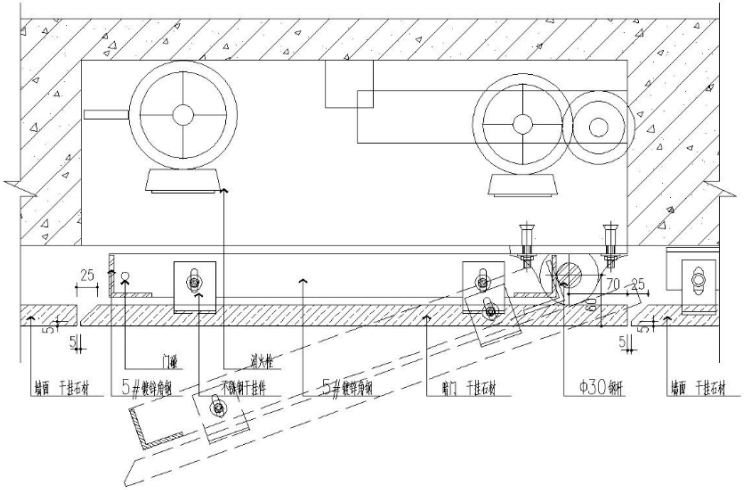

Slate wall mounting – fire hydrant door

1, the door frame at the separate set steel column and load-bearing steel beams.

2, the door shaft set the limit angle steel, to ensure that the fire hydrant door opening angle. 3, the door entrance and stone cross-seam flat.

1, fire hydrant door switch should be flexible, open angle is not less than 120 degrees,and ensure that “open door hydrant”.

2, the back of the access door skeleton, equipment and the gap around the wall should be closed treatment.

3, fire hydrant identification must be clear.

07

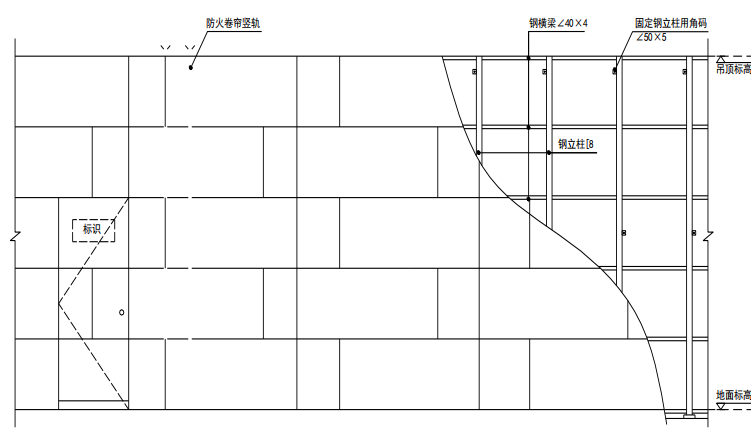

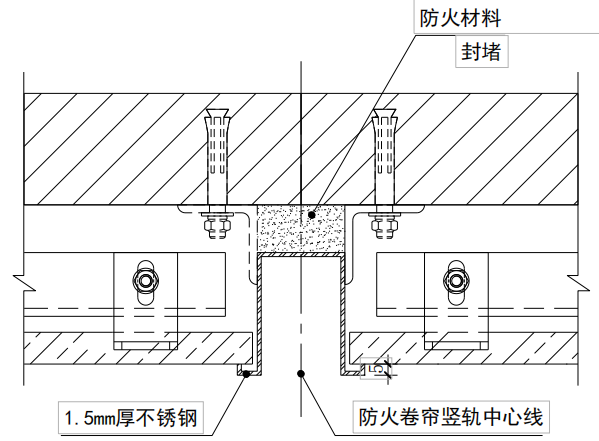

Slate wall mounting – fire curtain

1, in the construction of the fire curtain center line for accurate unified line, the vertical rail installation vertical deviation is not greater than 1mm.

2, the gap between the vertical rail and the structural wall application of fire-resistant materials sealed tightly, the fire resistance limit at the blocking area should be consistent with the curtain there.

08

Ceramic plate wall mounting

1, the main keel up and down the end with a thrombone fixed firmly.

2. Pre-buried parts (or rear buried parts), number of connectors, specifications, location, connection methods and anti-corrosion treatment of the trim panel installation works must meet the design requirements.

3, the rear buried parts of the site pull strength must meet the design requirements, trim panel installation must be solid.

4, the seams are uniform, the plates are smooth, the seams are dense, wide and narrow consistent, no misplacement.

09

Ceramic plate wall mounting — yang angle

1, the choice of curved plastic or stainless steel corner, face tile before the use of building adhesive fixed corner protection. The corners are stitched around the corner at 45 degrees, circled around the holes in the doors and windows.

2, block material Haitang Corner should be processed by manufacturers, Haitang Point should be glued treatment.

3, chamfer stitching, should be poured into 45 degrees stitching tight.

10

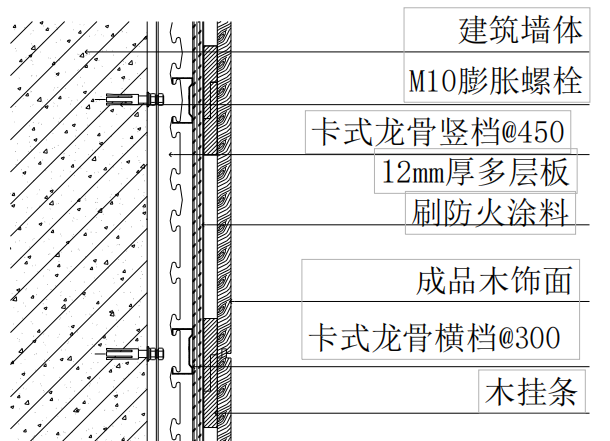

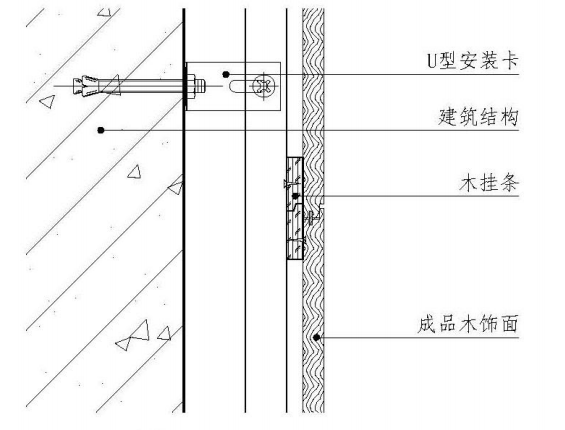

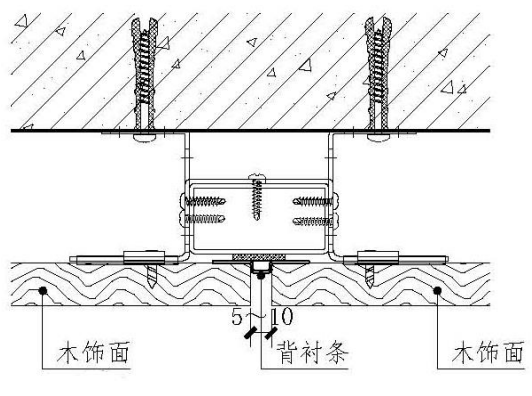

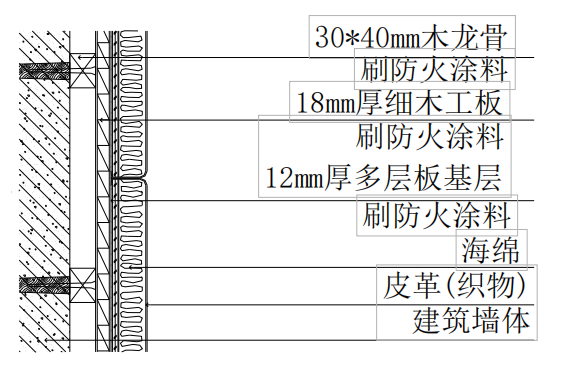

Plank wall mount

1, wood panel grass treatment should meet the requirements of fire protection design. The yang angle can be treated with yang angle bar, or it can be done in the form of one plate crimping another plate.

2, wood trim panel as far as possible in accordance with the standard plate size to split, the margin size by fine-tuning the plate seam to eliminate, installation should follow the principle from left to right, from bottom to top.

3, wood decoration panel should be consistent wood pattern, paint color uniform and meticulous, no color difference.

1, verticality of the façade ≤ 2mm.

2, surface flatness ≤ 1mm.

3, no cracks and defects on the surface, no nail eye.

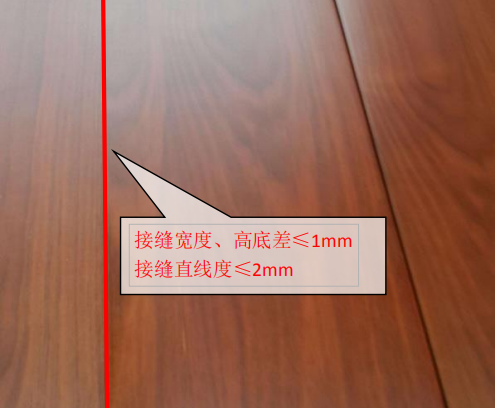

1, seam width, high bottom difference ≤1mm.

2, seam straightness ≤2mm.

3, the seams are dense and straight.

11

Board wall — Yangjiao

1, corner part of the use of the whole plate treatment, yang angle square, allowing deviation of ≤ 2mm.

2, wood decorative line groove straight, smooth, with the wall wood color consistent.

12

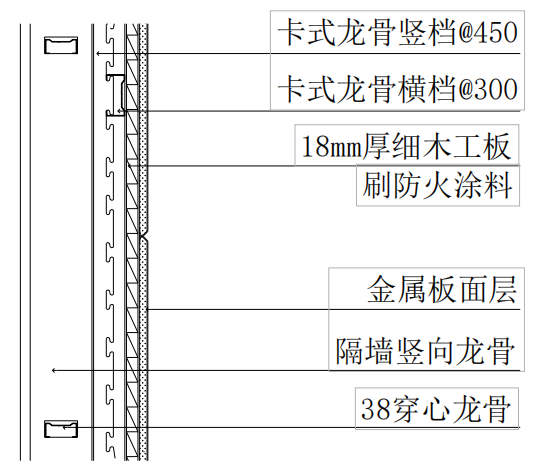

Metal plate wall

1, metal trim panel through the plate edge reserved fixed with steel keel, curved wall using straight plate folding line stitching can be fixed using the adjustment angle code. Keel and pendants should be hot galvanized parts, welds need to be rust-proof treatment.

2, should be accurate measurement of the scene, loft, fully consider the relationship with the ground, ceiling, so that the up and down echo, reasonable circle.

13

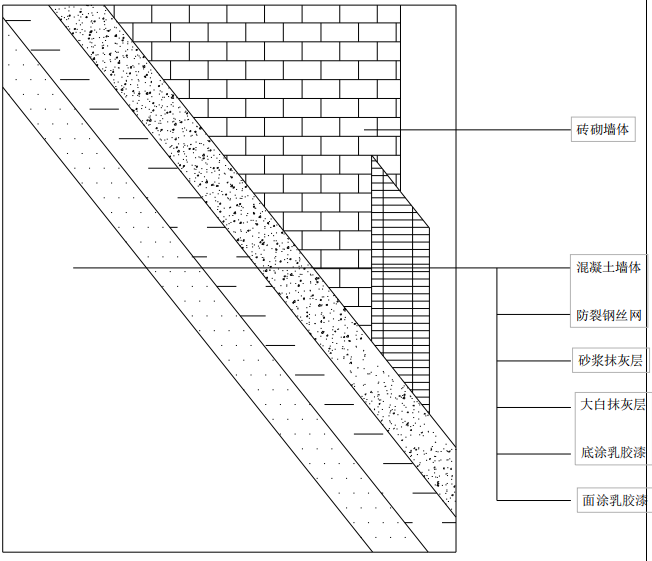

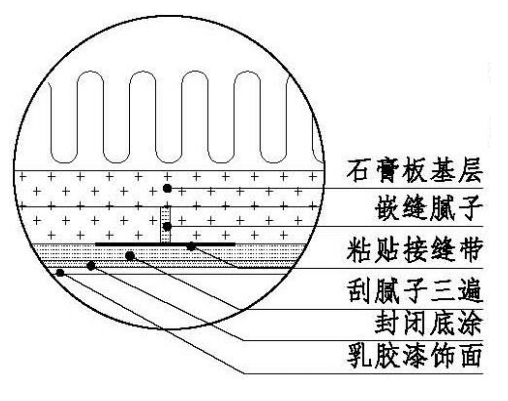

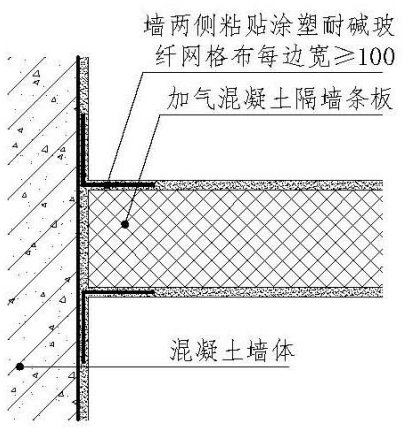

Paint the walls

1, the coating base should be flat, solid, solid, powder-free, peeling and cracks, water content is not greater than 8%.

2, evenly coated, bonded firmly, not to leak, seep through the bottom, cracking, peeling, powdering and rust.

3, paint color separation line should avoid yin and yang angle parts, evenly coated, clear contours, color separation line straight.

1, paint surface flat, allowing deviation of ≤2mm.

2, vertical façade, allowing deviation of ≤2mm.

3, the surface of the painted wall should be smooth, clean, uniform color, yin and yang angle square.

14

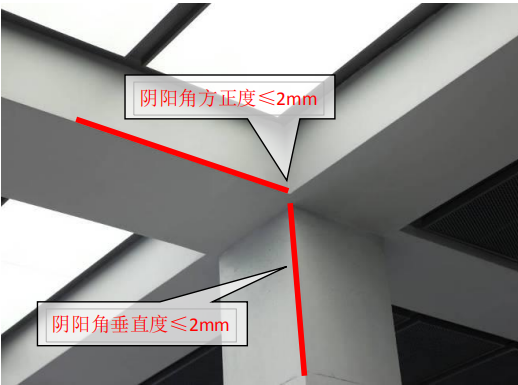

Painted wall — yin and yang angle

1, Yin and Yang angle square positiveness ≤ 2mm.

2, Yin and Yang angle verticality ≤ 2mm.

15

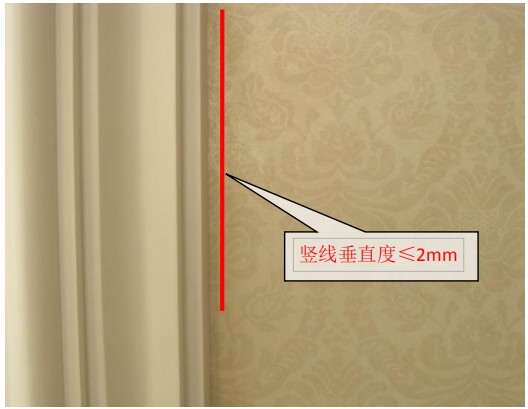

paste the wall

1, paste before the grass-roots moisture content shall not be greater than 8%. Grass-roots putty should be flat, solid, solid, should not have powder removal, peeling and cracks, and should be applied in accordance with the provisions of the closed base glue.

2, the surface of the wall cloth should be flat, consistent color, there must be no ripples, bubbles, cracks, creases and stains, yin corners should be connected to the light, yang corner should not have seams.

3, the wall paste after each piece of stitching should be horizontal vertical, stitching pattern should match, should not have off seams and obvious stitches, paste solid, there must be no missing paste, subsidies, off-layer, empty drum and cock edge.

4, paste decorative line straight with a variety of decorative lines, doorways, equipment boxes and different materials junction should be tight, straight, vertical vertical ≤ 2mm.

5, seam parts are not recommended to play glue, such as glue, glue color to be close to wallpaper color.

16

Paste wall – different material junctions

Different materials handover edge neat tight, straight hairless edge, flying thorns.

17

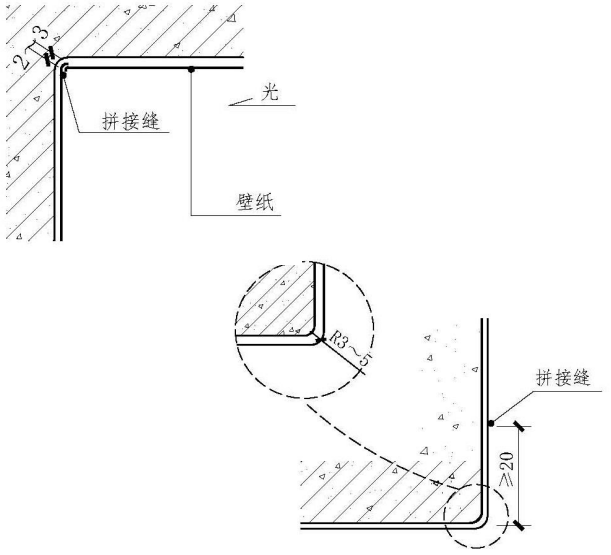

Paste wall — Yin and Yang angle

1, the yin and angle parts should be disconnected, smooth light hook.

2, yang corner parts should use the whole wallpaper, is strictly prohibited to build or stitch.

3, Yin and Yang angle to ensure straight.

18

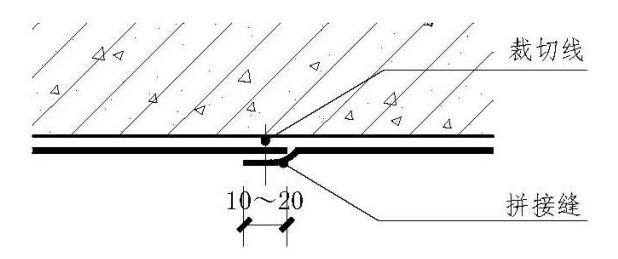

Paste the wall — stitching

1, wallpaper, wallpaper should be the whole paste, and unified pre-arranged to the flower stitching.

2, less than one should be paste in darker or less obvious parts.

3, seams should be horizontal vertical, stitch pattern should match, not to tie, and at 1m look up should not have off seams and obvious stitches.

19

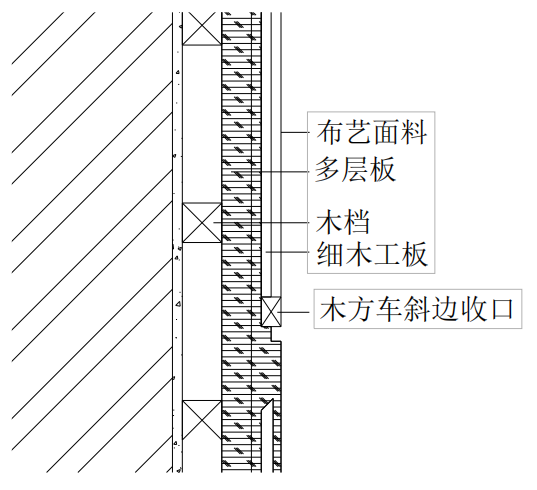

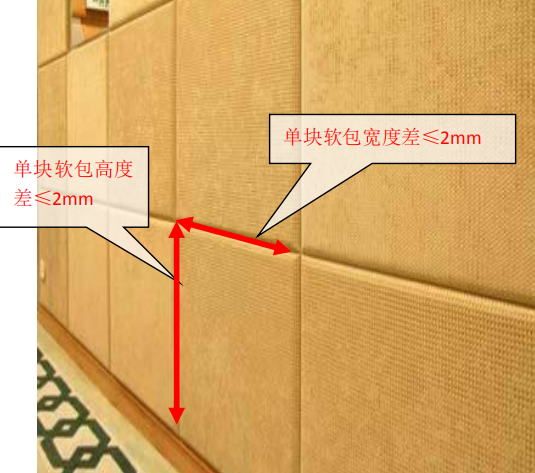

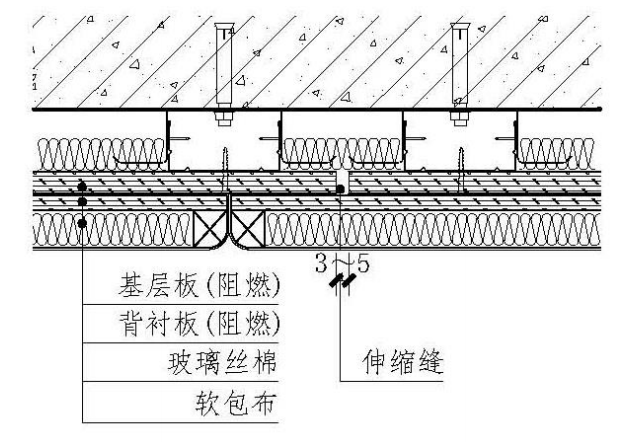

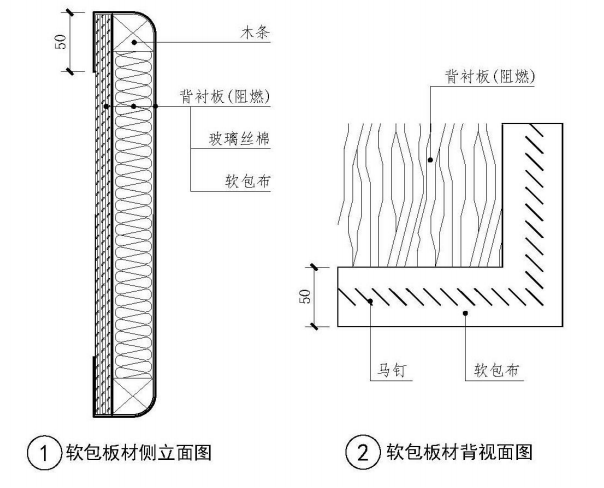

Soft-packed wall

1, soft bag engineering keel, lining, border installation should be solid, no warping, stitching should be straight. A single piece of soft-pack fabric should not have seams, around should be tightly pressurized.

2, soft package engineering surface should be flat, clean, there should be no bumps and creases. Patterns should be clear, colorless, the overall should be coordinated aesthetics. The filling material should be of the correct size, with a square angle, and the base bond is tight and firm. The border should be flat, straight, and seam-like. The colors and wood patterns of the varnish-coated wooden borders should be coordinated.

3, fabric surface should be flat without wrinkles, color consistent, the size is correct, tight moderate, the surface layer is quite beautiful, angular square, seam tight, group spelling end, complete.

1, single piece of soft bag width, height difference ≤2mm.

2, soft-pack fabric surface should be straight.

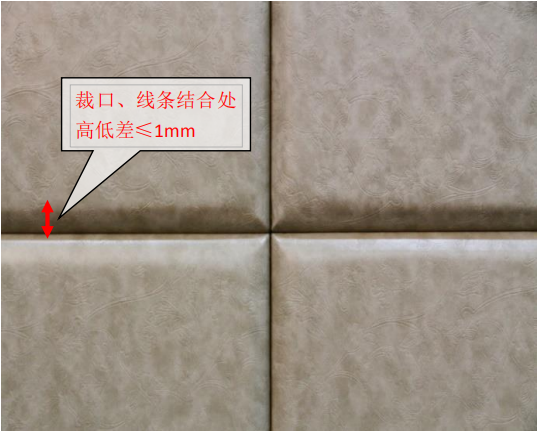

1, the thickness of the filler is consistent, cutting, line combination at the high and low difference ≤ 1mm.

2, fabric plug solid, corner line clear, smooth.

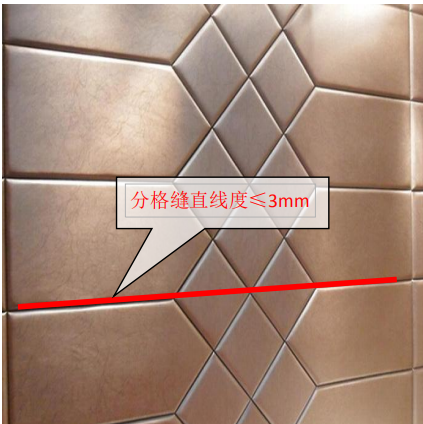

1, soft package layout stitching, grid seam straightness ≤ 3mm.

2, the surface should be flat, clean, straight lines, there should be no seams

– Roof and ceiling works –