Decorative project manager must know the 6 core management system, hardcover repair project management

The design plan of a decoration project is a prerequisite for the construction of construction, and it is necessary to formulate a realistic and well-designed project management plan before the construction of the decoration building.

Therefore, before the decoration construction, the relevant technical staff must fully understand the complex construction projects, and to the construction site to actively carry out field visits, in-depth study and analysis of the construction process may be various problems, for the construction process, construction environment, each procedure selected decoration materials, decoration equipment, and decoration methods are discussed and exchanged.

Today for hardcover repair projects in the construction process, project management characteristics, difficulties, such as analysis and summary, talk about how to do a good job of finishing project management.

01

Fine decoration process index

1.1

Grassroots section

Entry line: includes the cross-center axis, one-meter elevation line, wall finish face line, top ceiling line, top lamp positioning line, etc.

Ceiling finish project: grass-roots keel production, forced positioning, ceiling board, lamp opening.

Wall ground finish project: wall ribs to find flat, wall top primer finish.

Kitchen bathroom balcony grass-roots project: wall ribs to find flat, wall top primer finish.

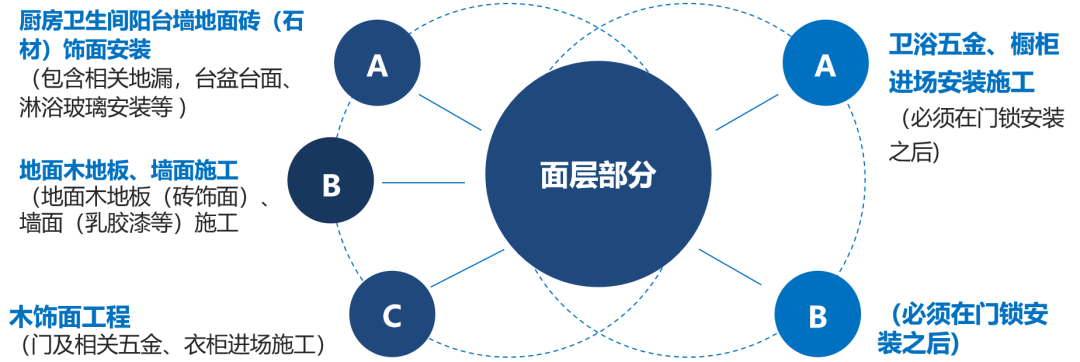

1.2

The portion of the surface layer

Kitchen bathroom balcony wall floor tile (stone) finish installation: including related floor leakage, basin countertop, shower glass installation, etc.

Groundwood flooring, wall construction: groundwood flooring (brick finish), wall (latex paint, etc.) construction.

Wood finish engineering: doors and related hardware, wardrobe entry construction.

Bathroom hardware, cabinet entry installation construction: must be installed after the door lock.

1.3

Closing, handing over parts

Sporadic closing: clothes rail, some electrical appliances finished.

Electrical and mechanical unit commissioning

Cleaning begins to hand over

Owner acceptance: property acceptance transfer

02

Fine decoration pre-entry precautions

2.1

Project perimeter, peripheral, construction environment inspection

Project surrounding environment: the project before entering the site to examine the project location (busy areas, suburban areas, surrounding facilities, etc.), affecting the transportation of materials, personnel accommodation, etc.

The peripheral environment of the site: the road conditions around the project, the operation of outdoor elevators, the time nodes of the ground road closure, the impact of material entry mode, vertical transportation of materials, and stacking location.

On-site construction environment: the site construction area windows have not been closed, underfloor heating and air conditioning equipment completion, civil site inspection. Need to consider the team material transportation mode, etc., with the construction of the regional surface division and other projects.

2.2

Notes on-site handover

We want to test the deviation of each wall, propose solutions, achieve the unity of size, for the completion of the household acceptance to do preparation.

Empty drums of civil wall painting layer We should carry out a careful inspection to ensure that the pass is followed by the handover, so as not to rework when we are surface construction, affecting the duration.

The closing handover with the façade decoration To put forward the closing plan in advance, as soon as possible to end the end with the outer wall, so as not to rain and other damage to our construction.

The handover with the installation unit should be comprehensive, such as every switch panel, every lamp should be carefully checked, the panel horizontal vertical, installation is solid, lighting installation meets the requirements, etc., confirmed qualified and then handed over, to avoid the completion of the handover and then found not in place, tearing each other.

2.3

Pre-targeted special planning

Need to be more early on the project inspection and the accumulation of construction experience over the years, the combination of the two, the preparation of special construction planning, and the team and owners to conduct comprehensive discussions.

03

Hardcover repair project control analysis

3.1

Material entry organization

Vertical transportation of large materials, before the demolition of construction elevators, large materials are all transported upstairs.

Statistical reporting of A-supply materials, acceptance of quantity and quality at the time of receipt, to avoid disputes at a later stage.

Materials to the scene test, due to large volume easy to early detection of problems and suppliers to communicate, such as stone (composite thickness), finished furniture, wallpaper, hardware (bathroom, door), lamps, taps.

3.2

The model gives directions in advance

The construction between the models is the project department’s understanding of the characteristics of the material, the confirmation process of the material brand.

The advance room of different household types is the understanding process of the project department on the whole construction process and the closing control.

A model of various materials and a one-to-one large-scale production, the end of the construction process model.

3.3

Insist on the implementation of the first inspection system

Workers in each process of the first construction, the project department personnel must be in place, unified standards, found problems resolved promptly, to later large-scale construction inspection. The items of the batch unified construction process must be first inspected, and the first inspection can be used for physical bottoming.

Raw materials into the scene, warehouse manager, construction staff to the scene inspection.

Before the material installation, the project department, team leader participate in the construction.

To be confirmed by the project department after the construction process to prepare the technical bottom and for the main construction personnel to cross the bottom (site bottom).

Technical bottoming (oral, written, physical) for the physical bottom of the project.

3.4

Bridge management with matching units

Curtain wall units: curtain wall closure time, interlayer blocking time, opening fan installation time, curtain wall aluminum frame and curtain box closing, ground and curtain wall aluminum frame closing, wall and curtain wall aluminum frame closing.

Strong and weak power units: the control of the elevation, according to the layout (brick, stone) wall centered control, the location of the hole, the size of the control, hidden pipeline layout requirements, some points although correct, but because of the covert pipeline impact elevation led to point displacement.

Water supply and drainage and fire units: up and down water point with the release line control, different surface level of the upper water point out of the wall distance size control, all pipe hidden direction control, pipe pressure, and water test requirements, I project department to participate in the protection of the requirements of the finished product.

Cabinet units: drawings of the deepening of the closing, unified household size control, entry time requirements, material stacking requirements, construction process Chinese management requirements, the installation process of our quality monitoring, construction order.

Floor units: installation control line and horizontal elevation line control, laying direction requirements, closing requirements (stone, wardrobe, door cover), floor reserved door hardware (door suction, folding door track) requirements, installation floor order requirements, construction process Chinese management requirements, finished product protection requirements.

3.5

Preemption process management

Increase the bottom of personnel, the bottom is a continuous process, workers are mobile, from the start to the end of the maintenance process personnel are constantly changing.

The tracking of orders, materials in the process of pre-emption is the first, can only appear materials and other people, but not people and other materials.

After the completion of the unit handed over to us, the transfer process requires gadgets need not be installed, pending door lock installation.

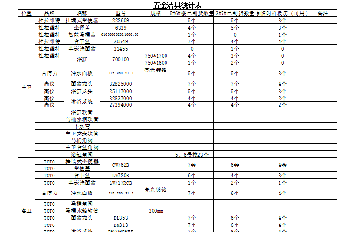

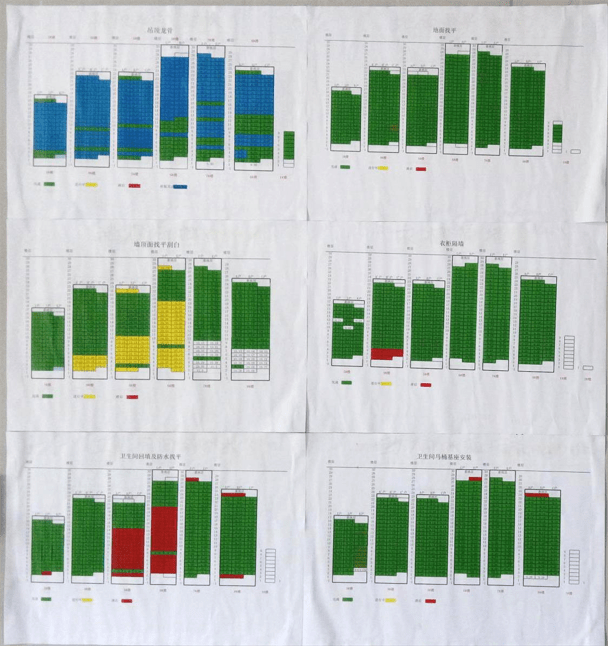

Progress comparison analysis, through comparative analysis, to find materials or labor shortage, timely communication with suppliers, teams.

On-site use of column analysis table to count the progress of fieldwork, according to real-time progress, to coordinate management.

3.6

Quality control points

Responsibility to the point to the person: construction situation to achieve the bottom of everyone’s hearts, at a glance, to reduce the quality of common diseases.

Control into the controller: is to require each manager to have a strong sense of responsibility, execution, and endurance over and over again to repeat the inspection of each process.

Management of material costs: adhere to the assessment of materials, reasonable arrangement of construction processes and construction processes, strengthen the awareness of the protection of finished products.

Technical bottom: on-site team mutual inspection and quality training.

The inspection system: Because of the number of floors, rooms, everyone can not carry out a comprehensive inspection every day, project staff to develop a touring floor, to ensure that the entire site’s everyday inspection does not leak layers every.

3.7

Control points for progress and workforce arrangements

Planning in place, strengthen the technical and technical standards of the bottom, in each process before the construction of special technical bottom.

Some grasp is not allowed to make small samples and large-scale production, as well as stone, wood finishes of raw materials and processing capacity control.

The focus is on the control of people, the main is to check and rectify, the construction site situation at good fingertips, timely detection of problems.

Strengthen the construction concept of doing a piece of the collection, really achieve the requirements of productization, after the completion of a large area of product packaging conditions.

On-site knowledge, especially of super-high-rise buildings, and constraints on workers’ commuting and material transportation (workers’ commute; material transportation).

The entry plan of the basic materials and the order plan of the main surface materials, the project department should control the follow-up implementation.

04

Fine decoration cost control analysis

4.1

Process practices unified bottoming and finished management

According to the quotation and the actual situation on site, the construction process to carry out the multi-scheme comparison, to ensure quality at the same time to minimize the cost, but in the implementation process, there will be deviations, mainly pay attention to the following points.

No full staff: in the process, there are still some workers who did not fully follow the project department’s delivery order for construction, the need to do this kind of work all workers and with classes together to hand over the bottom.

Inspection is not in place: when the deviation is found to be unable to rectify, should be at the beginning of each sub-project construction by a special focus inspection, to formerly rectified.

Productized construction attention points: the unity of the household surface layer, the unified exchange of materials, the standardization of size specifications, uniformization, standardization of packaging protection, and so on.

4.2

Material-related controls

Material Early warning line quantity determination: the process does not understand lead to measurement errors, this work must have construction staff, budget staff, with the monitor combined with the base drawings to participate in the calculation, and let the monitor sign confirmation.

Control of material loss: basic materials need to be fixed-scale processing, reduce losses, but pay attention to the bottom and unified ingredients, for the unified approach to take a centralized stacking of centralized processing, by the installation workers to lead semi-finished products to the site installation, such as door cover carpentry board grass-roots, curtain box woodworking board grass-roots, ceiling shape, wall tiles and so on.

Temporary facilities control: site special woodworking board usage is often far more than the settlement volume, a large piece is a team to do warehouse, dormitory bed board, dormitory table, including on-site utilities, to strictly control this piece.

4.3

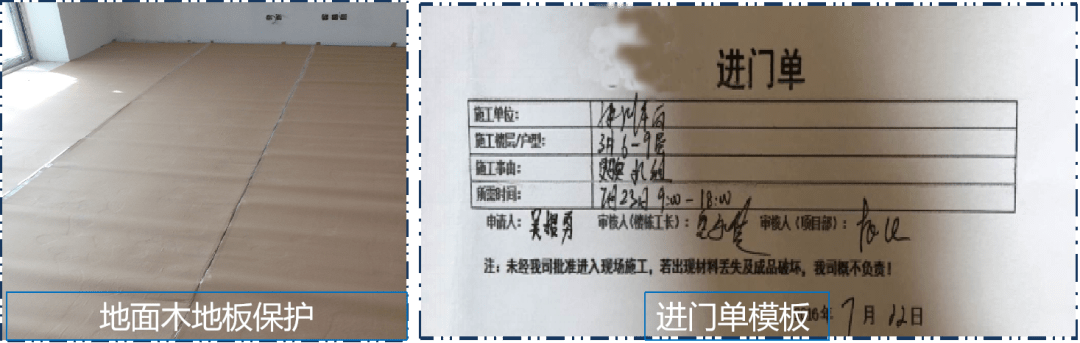

Control of finished product protection

Avoid damage to other installation units, especially hydropower, air-conditioning units, and give them written reminders in advance.

Avoid the loss and destruction of hardware, ware, etc. in the later period, and strengthen the implementation of the door opening system; Commissioner opens the door system, controls too many people flow activities, in and out of the indoor construction have the corresponding door.

Protection of cabinets, wardrobes, etc., and finished products such as wooden floors, wood finishes, stone, etc.

05

Fine decoration to avoid the key analysis

5.1

Latex paint anti-cracking control point

Wall cracking measures:

Different materials are flushed with the gypsum board using adhesive gypsum to tie 10CM

Window sleeve hard joint part cement painting

Top corner anti-cracking measures: top corner plus L-type plate, reinforced corner, to prevent cracking.

The corner base is connected with an edge keel

Corner sticker tape when batch gray

Corner first layer board needs “L” type overall gypsum, board

5.2

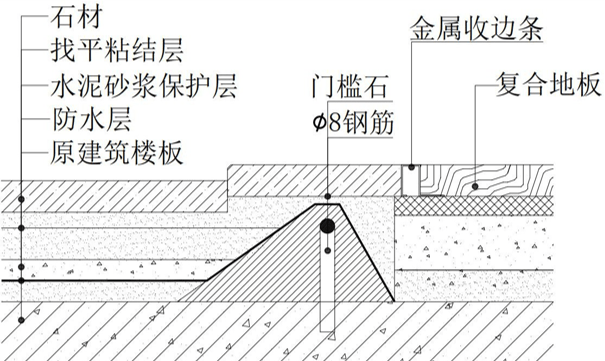

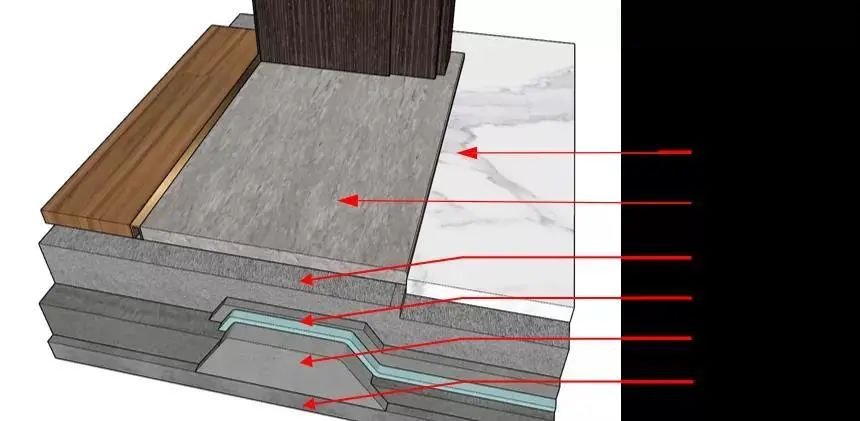

Waterproofing process and waterproof control points

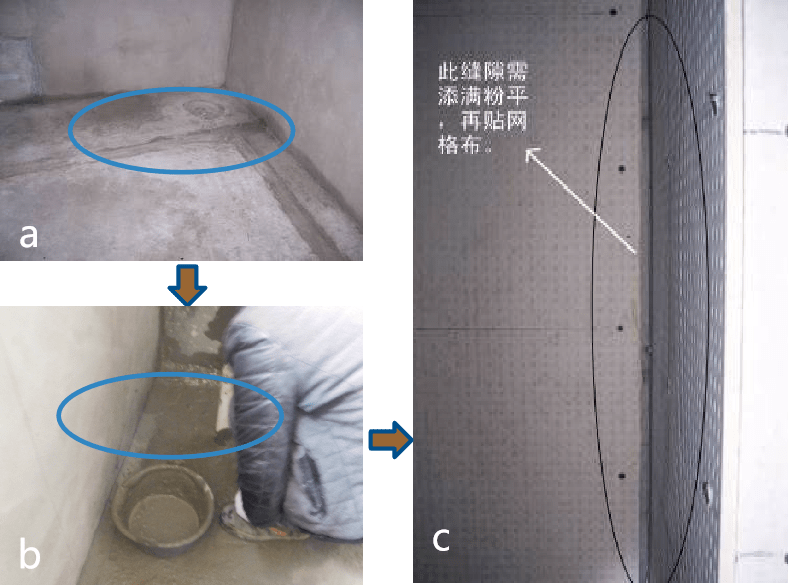

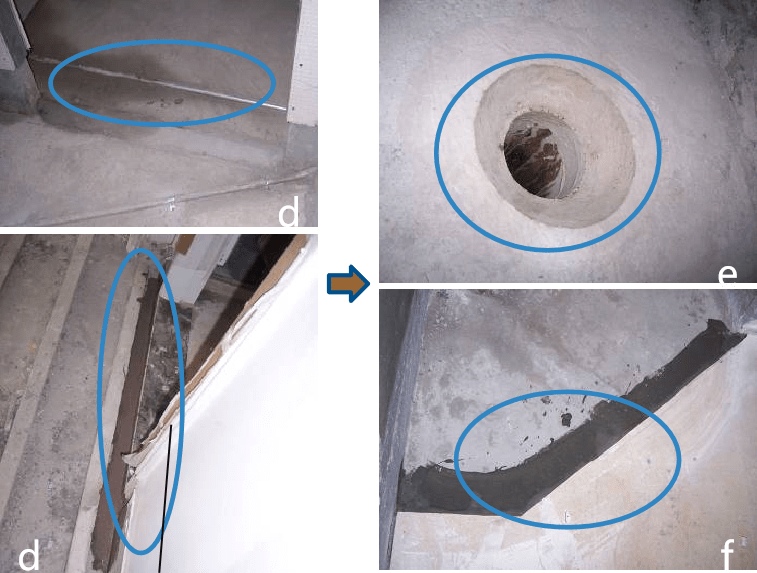

Waterproofing process requirements:

a grass-roots clean-up; b, yin angle need to do first arc treatment, water does not leak to block;c, new and old walls sewn mesh cloth.

Waterproof control point:

d, the threshold is waterproof with a water-stopping band brush, waterproof should be brushed to the dry area and turned over 30MM; e, ground leakage position is treated as a funnel;f, shower room water belt.

5.3

The main points of control of the anti-aircraft drum process

Before the construction, check the original wall for empty drums, fall off and other hidden dangers, must not blindly start work; If there is a corresponding situation, need timely feedback knock-out, repainting.

To prevent the glass brick empty drum and fall off, the glass brick before the spread of its full back glue treatment, so the back glue process is particularly important, the focus of inspection (inspection focus: back glue to the edge uniform not exposed bottom), Construction using special tile binder construction.

5.4

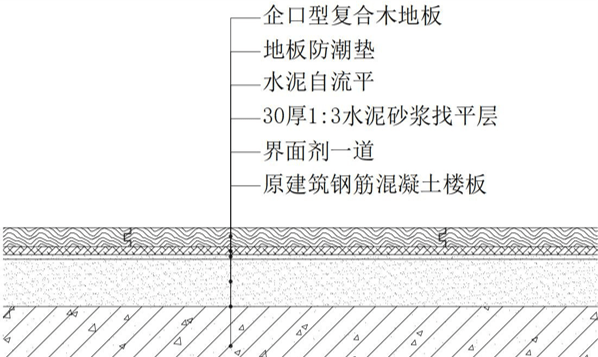

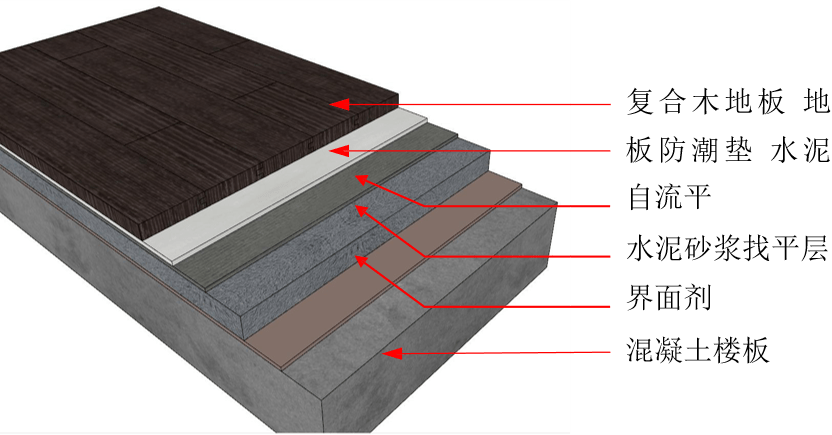

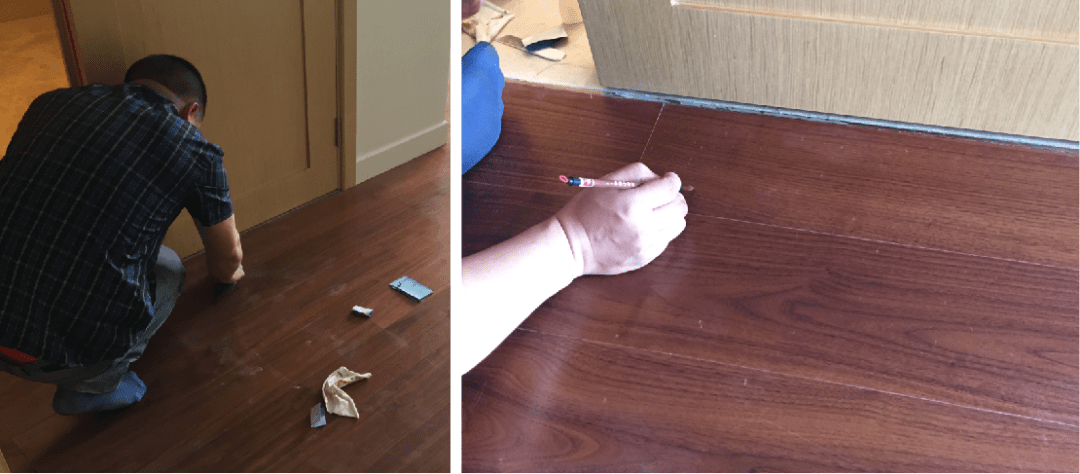

Wood flooring construction

Cement compacted surface requires a flat surface, dry, uneven surface with cement putty scraping flat, flatness ± 2mm.

When laying moisture-proof film, the direction of laying is perpendicular to the wooden floor, and the film join width is not less than 150to200mm.

The floor mounting plate is tightly sewn to the height difference between the two wooden floors, not more than 1mm, maintaining a 10mm gap with the wall, do not leak the floor glue.

5.5

Wet area threshold construction

Toilet threshold Stone base should be set up to stop the water belt, and with the ground to do unified waterproof.

The water-stopping belt should be higher than the waterproof area binding layer 5mm-8mm.

The threshold stone placement is carried out according to the finished surface of the wall and the height of the ground.

06

Notes for post-service points

6.1

wooden floors

Case description: ground wooden floor in the later stage of scratches and other conditions

Cause: The failure to clean the floor when the floor leather and corrugated boards result in many scratches on the wooden floor.

Avoidance measures: wood floor finished product protection must be vacuumed clean, and then wiped clean with a dry cloth, to do finished product protection.

Case description: the floor wood floor later part of the drum, there is a noise

Cause:(1), stainless steel opening strip reservation width is too narrow;(2), workers During the construction process, unsupervised in place, the wall around the telescopic seam reserved too small;(3), indoor wood Floor area is too large, there is no split shrink seam.

Avoidance measures: manufacturers must detect the deformation coefficient (especially 8MM thick laminate flooring) in advance, the floor should be reserved around less than 5MM telescopic seams, the site large area of the paving must be divided into areas reserved telescopic seams (more than 8M on-site). to reserve the telescopic seams).

6.2

Leaking

Case description: the late bathroom there is a wall root seepage situation

Cause:(1), threshold stone under the guide wall due to underfloor construction slotting, did not do waterproof treatment, resulting in toilet water seepage;(2), waterproofing of the ground The wall side of the door cover is not done.

Avoidance measures:(1), waterproof before the closed water test must be done, pipe and yin corner must be checked carefully;(2), the door to stop water can prevent damage, waterproof construction must do the outside of the wall, forming a whole waterproof;(3), through the door Stone must cross the bottom to do the wet paving process, to ensure that the bathroom area waterproof integrity.

6.3

Latex paint wall

Case description: there is a large area of cracking, peeling, and other conditions

Causes:(1), the previous wall flour brush ratio problem, not dry on putty treatment, late temperature changes lead to the mortar layer shrink into pieces, with the surface layer shedding together;(2), a secondary structure junction mishandled resulting in cracking.

Avoidance measures:(1), wall flour brush before handling a secondary structure junction, to ensure that the seams filled with full, with wire mesh for joint reinforcement;(2), wall flour brush mortar ratio must comply with the specification requirements, wall wetting after the whitewash processing, in the batch of putty to find a flat before the party must check the whitewash in advance Whether the wall is a hidden danger;(3), painted too thick place must supervise the construction process to prevent workers from forming once, to layer paint.

6.4

Fireproof roll curtain

Case description: Fire curtain and ceiling junction is not handled

Cause: The decoration unit and fire installation unit is not in place, in the fire curtain and ceiling junction, the construction process often does not pay attention to the internal sealing process.

Avoidance measures: Ceiling wire rod (or main keel) must not be close to or in contact with air conditioning ventilation ducts, let alone wrapped in one place.

6.5

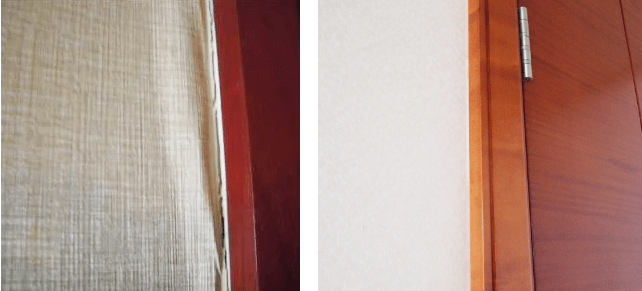

wallpaper

Case description: Empty drums appear on wall wallpaper near the door cover

Cause: Between the door cover edge and the adjacent finish material, due to the shrinkage of the base material easily cause cracks, the emergence of empty drums;

Avoidance measures: door frame and wall left empty parts, the use of cement mortar painting or with wood gypsum plate sealing, not to use foaming agent;

6.6

Soft and hard pack

Case description: soft and hard bags with gun nails fixed, the marks of nails obvious

Cause: Hard and soft packages generally do not use gun nails fixed, affect the perception, damage the surface layer. In special cases, it can only be used locally outside the normal line of sight.

Avoidance measures: the installation of soft and hard bags must be fixed with nails, can be hidden in the area or outside the normal line of sight of the person to be fixed, so that people in the normal line of sight observation range, can not see the use of gun nail traces.

How to control the quality of hardcover room as a whole, to avoid a large number of maintenance later, has become a very worthy of discussion of the problem, I hope this article can bring help to everyone.